Making Custom Metal Forms for Airplane Maintenance, Repair, and Overhaul

How Marlin Steel Engineers Wire Baskets for the Aerospace Industry

How Marlin Steel Engineers Wire Baskets for the Aerospace Industry

Marlin Steel makes custom metal baskets to fit any need, including the needs of the aerospace industry. For years, clients such as American Airlines, Delta, and United Airlines have relied on the precision engineering and quality of Marlin Steel’s custom-crafted wire and sheet metal baskets for their parts and materials handling needs.

From ultrasonic parts washing baskets for extra-delicate parts that must have a flawless finish, to rough and rugged materials handling baskets for moving large objects from point A to point B, Marlin Steel has what it takes to meet the needs of the aerospace industry’s toughest jobs.

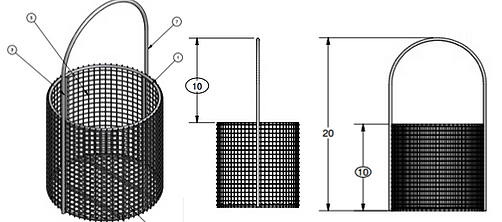

This material handling basket is used by American Airlines

This material handling basket is used by American Airlines

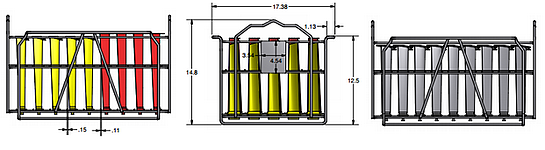

This is an engine blade basket designed by Marlin Steel for Delta Airlines

This is an engine blade basket designed by Marlin Steel for Delta Airlines

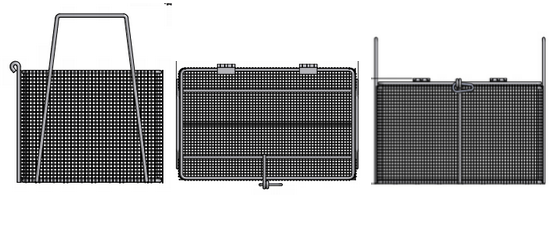

This material handling basket with a locking, hinged lid is used by United Airlines

How does Marlin Steel ensure that every basket is made to your exacting needs and specifications? It all begins with over $4 million in robotic manufacturing equipment that is used in every phase of the manufacturing process. This equipment includes:

Combined with the Marlin Steel engineering team’s years of experience in designing and building custom baskets, these marvels of factory automation allow Marlin Steel to deliver “quality, engineered quick” for companies involved in maintaining, repairing, or overhauling aircraft and their expensive, delicate parts.

When lives depend on the consistency and reliability of parts, you need the best materials handling baskets for the job, baskets that Marlin Steel provides with greater speed and consistency than cheap overseas competitors who rely only on manual labor that can’t meet your exacting tolerances. If you'd like to see what Marlin Steel can do for your business, contact us here.

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797