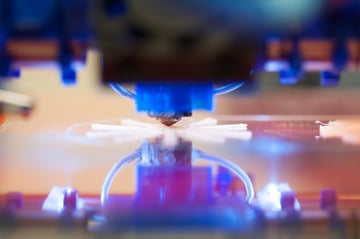

Additive manufacturing, or 3D printing as it’s more commonly known, is a technology that has been around for a while. In fact, according to pwc.com, the technology “has existed in some form since the 1980s.” Watch Marlin Steel's 3D printer in action below!

However, it wasn’t until fairly recently that 3D printing has begun to really catch on in the manufacturing industry. Even now, the primary use of 3D printing is to rapidly prototype parts or experiment with designs, as a 3D printer can easily make complicated shapes without the need for specialte tooling or setup.

Why? Well, there are several reasons, such as low manufacturing speed and limitations on useable materials in the process.

However, there are several new big breakthroughs in 3D printing that may just change it from a small, niche assembly method into the primary tool for many manufacturing companies. What are these breakthroughs, and how will they affect 3D printing?

Here’s a short list of some of the bigger breakthroughs in 3D printing technology:

More Efficient Assembly Technology

Early 3D printers had a major limitation in that to assemble anything, inkjet printer heads had to be used to sequentially deposit material onto a powder bed. This meant that if you were assembling an object in a printer that was 2’ wide by 3’ high, and your printer’s assembly chamber was 3’ wide and 3’ long, you would have to use up 36 cubic feet of powder bed material per part assembled (3’ x 3’ x 4’ = 36’).

Since then, newer technologies such as extrusion and sintering have been introduced which largely eliminate the need for a solid bed of powder material.

These techniques for adding material made additive manufacturing more cost effective, improving its viability as a manufacturing technique.

Multiple Extrusion Head Printing

Another major limitation of extrusion-style 3D printing was that there was only one extrusion head to deposit material, which imposed certain limitations on the printing process.

Another major limitation of extrusion-style 3D printing was that there was only one extrusion head to deposit material, which imposed certain limitations on the printing process.

For example, with one extrusion head, you were limited to using a single type of material in the printing process. Another limitation was that certain shapes would be impossible to make using a single extrusion head, as they would have you trying to “print” the edge of a shape onto open air.

The creation of dual-extrusion head printing technology helped to enable the creation of much more complicated parts and shapes.

For example, one extrusion head could be loaded with a “filler” material that could be dissolved with a simple solvent. This gives you something to lay the edge of a shape on so that printing of highly complicated parts can be completed.

Or, you could load two different kinds of polymer into the extrusion heads with different hardness and elasticity values, enabling you to create more complex parts to meet your needs.

Expansion of Usable Materials for Printing

For a long time, the materials that a 3D-printed object could be made out of were quite limited. In recent years, however, that has changed.

While the extrusion process still largely deals with polymer materials, the list of printable polymers has expanded greatly. The introduction of sintering, on the other hand, has expanded the list of printable materials to include certain metals as well.

However, one of the more exciting developments for 3D printing might be for medical manufacturers: the ability to create artificial organs from synthetically-crafted biological material.

As pointed out in a technologyreview.com article, there are researchers out there that are creating new “inks” that can give 3D printers the ability to print with a wider assortment of materials, “from living cells to semiconductors, mixing and matching the ‘inks’ with precision?”

In the article, the authors state that “Jennifer Lewis, a materials scientist at Harvard University, is developing the chemistry and machines to make that possible.” This technology could massively expand the market for 3D printing, and potentially save lives in the process.

Deltabot Printing Configurations

Here’s a major innovation that was highlighted in a pwc.com article on the subject of 3D printing.

Here’s a major innovation that was highlighted in a pwc.com article on the subject of 3D printing.

Most 3D printers use the older Cartesian architecture for printing. What is the Cartesian architecture? According to pwc.com, Cartesian printers “move a printhead in two dimensions on a plane.” Basically, these systems are limited to printing one layer at a time on the X and Y axes.

However, there’s a new printer configuration that might just overtake the popular Cartesian architecture: Deltabot printers.

These printers use a series of parallelograms in their printing arms similar to a robot. As pointed out in the pwc.com article, “the Delta printers are going to basically take over all the Cartesian printers, because the have some significant benefits, one of which is speed.” The use of more fluid, complicated arm motions enhance the flexibility of the printing machine greatly, and enable vertical printing over simple layer-by-layer printing.

What else does the future of 3D printing hold? Who knows?

The only thing that is certain is that, as time goes on and more resources are put into researching and improving this technology, it will become more capable and efficient, making it an ever-more-attractive option for manufacturers in many different industries.

.gif)