All across America, manufacturers both large and small are looking to expand their product lines or update their existing ones to stay current in changing markets. This frequently calls for the creation of new parts that are entirely different from previous ones.

All across America, manufacturers both large and small are looking to expand their product lines or update their existing ones to stay current in changing markets. This frequently calls for the creation of new parts that are entirely different from previous ones.

New parts, particularly ones that are significantly different in design than old ones, may require new wash processes to get clean. Sometimes, this may even require new parts washing baskets.

Why? There are a few reasons a new part might require new baskets, such as:

-

Old Baskets don’t fit. When the design of a new part is significantly different from the old part(s), the old basket design might not fit the dimensions of the new part.

-

Old Baskets cannot survive new Wash/Finish Process. Some new parts lines, or even just new finishing standards for existing parts, may require a new type of parts finishing or washing cycle. If the old baskets are not designed to survive the new process (perhaps because a more corrosive chemical is added to the process), then they won’t be useful for very long, even if the parts still fit.

-

Old Baskets are worn or damaged. Older baskets, particularly ones that weren’t built to the right specifications in the first place, will wear out over time. When baskets become deformed from years and years of stress, they need to be replaced, and the production of a new part may be just the right time to find a replacement.

In a recent custom steel basket order from a client who was beginning production on a new line of gears and assorted other parts for a new product, the above 3 factors all played a part in their decision to place an order for new custom steel baskets.

The Needs of the Customer

To properly identify the needs of the customer, we first had them fill out a custom basket questionnaire loaded with questions meant to reveal the details of what the baskets would be used for an the forces they would be exposed to. Knowing the specifics of the application(s) the baskets will be used for helps to better plan out the design of the basket as well as determine what features the basket should have.

For this particular customer, there was a need for two different custom-fitted basket designs, as more than one type of part was to be washed. Both baskets had several features in common, such as:

-

Lids. Both baskets were fitted with a hinged lid that would latch shut to hold parts securely in place. This would help to prevent parts from falling out of the basket during a wash or finish process.

-

Handles. Both baskets needed to be designed for ease of manual, bare-handed handling in between wash/finish processes. To accommodate easy handling, large handles were added to the exterior of both baskets for bare-handed gripping. Because of the need for bare-handed manual handling, the baskets also needed to be thoroughly deburred to prevent potential injuries.

-

Dividers. Both baskets are designed to hold six parts simultaneously, each one in its own little chamber inside the basket. To allow this, each basket had a divider permanently welded into it. By welding the dividers in place, their structural integrity is increased and the dividers themselves are less likely to fall out and get lost.

-

Materials. Both baskets were made entirely from natural finish, grade 304 stainless steel. This is a popular choice for many applications because 304 stainless steel has a good level of corrosion resistance and tensile strength, while being more cost effective than some other stainless steel alloys.

While many things about these two baskets are similar, there are also a few distinct differences between the two as well.

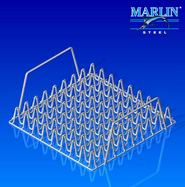

For example, the nature of the dividers is different in the two baskets. For basket #837013, the divider is made from cut sheet metal laid horizontally across the basket. There are six holes cut into the sheet metal, creating a 3 x 3 grid of slots for the parts to fit into. These slots can perfectly accommodate two sets of parts, one short set of parts and a tall set.

For example, the nature of the dividers is different in the two baskets. For basket #837013, the divider is made from cut sheet metal laid horizontally across the basket. There are six holes cut into the sheet metal, creating a 3 x 3 grid of slots for the parts to fit into. These slots can perfectly accommodate two sets of parts, one short set of parts and a tall set.

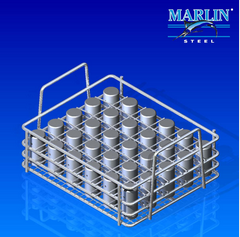

In basket #837016, on the other hand, the dividers are made from a simple set of steel wire bars laid across the inside of the basket, dividing it into six compartments that can accommodate rectangular parts.

Also, basket #837013 is covered in a fine wire mesh, whereas the other basket’s frame is left naked, with lots of open space. Part of the reason for this is that some of the parts to be held in basket #837013 are small, less than half as tall as the basket’s cavity. If these parts were to move during the wash cycle, they might fall out without such a complete enclosure. Basket #837016, however, is only holding one kind of part, a part whose dimensions fit perfectly within the enclosure, preventing the part from coming loose and falling from the basket.

Marlin Steel’s engineers have years of experience in creating custom metal parts washing baskets for a variety of applications. With this hard-earned knowledge, they can quickly identify the best way to create a steel basket that best suits your needs. By using advanced computer modeling software, they can test their designs to see if they’ll work before tooling for the basket even begins.

Learn more about how Marlin Steel builds a better basket that delivers quality engineered quick today!

.gif)