From Drew Greenblatt's latest column on Inc.com on why safety and sustainability go hand in hand as important objectives for business -- with help from the American Society of Safety Engineers. Thanks, ASSE:

I recently Googled the word “sustainability” and these are the headlines I found: “Global Environmental Change and Sustainability,” “5 Traits Essential for Sustainability Leadership,” and “Top 10 Cities Leading in Urban Sustainability.”

Then I Googled the word “safety” for the same period and a dominant story was “Pittsburgh Steelers Score in 3 Seconds on Titans Opening-Kickoff Safety.”

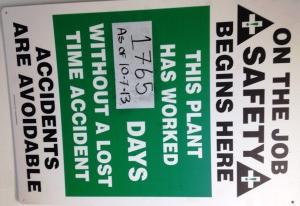

We're now at 1,765 consecutive days without a lost-time accident at Marlin Steel

We're now at 1,765 consecutive days without a lost-time accident at Marlin SteelSafety — that is, preventing injury or worse — isn’t the hip, eco-friendly topic that sustainability has become in recent years. But in workplaces like ours sustainability and safety are both essential and in fact go together: Sustainable practices seek to avoid waste, and the risk of injury is greater in places where mess and waste fester.

Many companies have gotten religion on sustainability. They realize it’s good for their mission, their operation, and of course their public image. Safety might seem an objective less easy to rally around. But I think smart companies grasp its importance and go above and beyond what is required.

David Coble, who runs a safety consultancy in North Carolina and chairs the Manufacturing Practice Specialty Group of the American Society of Safety Engineers, points out that safety and sustainability have gone hand in hand for a long time. The general industry standards of OSHA, the Occupational Safety and Health Administration, he notes, include dozens of references to “housekeeping.” And they were written in 1910, long before the concept of sustainability had the cachet it does now.

“I think ‘green’ is a term more associated with controlling wastes and protecting the environment,” he said. “We safety folks haven't used the word ‘sustainable,’ but that is what has been meant. Safety and health management systems are effective when they are continuous, prevent injuries and illnesses (a type of waste), and are continuously improving.”

http://youtu.be/QAzW1FoMXg4

In our business, the increased use of technology and automation has fueled a revolution in both safety and sustainable, lean manufacturing practices. Better automation has certainly made Marlin Steel a safer environment since many of the more physical, repetitive, “boring” tasks like moving heavy steel coils, bending steel wire, and cutting sheet metal are now performed by automation. At our factory and at industrial clients we’ve visited, lean manufacturing principles have also led to redesigns of the factory floor to improve ergonomics and reduce unnecessary movement. The dramatic rise in health care and insurance costs has also propelled safety in manufacturing environments.

The message is breaking through. The Bureau of Labor Statistics recently reported a preliminary number of fatal work injuries in 2012 of 4,383 --– a frightening number, yes, but also the second lowest total in 20 years.

Michael Coleman, a safety manager for Tyson Foods and administrator of the ASSE Manufacturing Practice Specialty, told me he thinks it’s only a matter of time before a safety focus finds its way to operations in third-world countries where high-risk conditions suppress cost. Indeed, practices that improve safety and sustainability should be goals for business, and for mankind, the world over.

.gif)