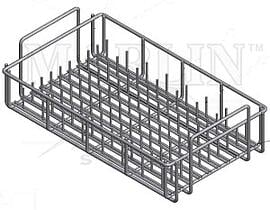

Marlin Steel designed a “pin rack” for a manufacturer of parts wash equipment, to wash oils and contaminants off newly fabricated fittings and valves. The racks were customized to accommodate the smaller wash stations that the facility used in place of a larger central wash station. The change reduced movement, improved efficiency and sped the flow of thousands of parts -- goals of a "lean" manufacturing facility. The pin system concept was an efficient way to secure various parts while protecting external part threads and allowing for thorough washing, rinsing and heat-dry.

Marlin Steel designed a “pin rack” for a manufacturer of parts wash equipment, to wash oils and contaminants off newly fabricated fittings and valves. The racks were customized to accommodate the smaller wash stations that the facility used in place of a larger central wash station. The change reduced movement, improved efficiency and sped the flow of thousands of parts -- goals of a "lean" manufacturing facility. The pin system concept was an efficient way to secure various parts while protecting external part threads and allowing for thorough washing, rinsing and heat-dry.How We Helped a Midwest Manufacturer Lean Out

July 11, 2013 | Lean Manufacturing, Stainless Steel Baskets, Marlin Steel Case Studies

.gif)