Over the years, Marlin Steel’s engineers have worked on many different custom parts washing wire basket designs. Some customers need an all-new basket design to be made from scratch to hold a new type of part, while others simply need to replace existing baskets that are becoming too worn to be used safely.

Over the years, Marlin Steel’s engineers have worked on many different custom parts washing wire basket designs. Some customers need an all-new basket design to be made from scratch to hold a new type of part, while others simply need to replace existing baskets that are becoming too worn to be used safely.

When a customer needs to replace an existing basket with a new one, they often send us their design files of the old basket to use to replicate the old design. Sometimes, however, there is a fatal flaw in the old basket design that caused it to fail prematurely. Because of this possibility, Marlin Steel’s engineers will test existing basket designs just as rigorously as they would a new basket.

Testing Existing Designs

How do Marlin Steel engineers test a custom wire basket design? By processing the design into an autoCAD file and running the design through virtual testing using the Autodesk simulation software that they would use for a new basket design.

Through the Autodesk software, the design can be tested for weaknesses or flaws that would otherwise only be revealed after hundreds of uses in real-world testing. When such flaws are found, Marlin Steel engineers are alerted to the failure and its cause so that they can formulate a solution.

Improving on Existing Designs

In a recent custom parts basket order, the customer sent Marlin’s engineers a basket and a .STEP file for reference to use to aid the design process. The existing basket design worked for the washing of the customer’s part, but the dimensions of the existing basket were slightly off of what was optimal. This small flaw resulted in an increased risk of damage to the parts being washed and basket failure.

In a recent custom parts basket order, the customer sent Marlin’s engineers a basket and a .STEP file for reference to use to aid the design process. The existing basket design worked for the washing of the customer’s part, but the dimensions of the existing basket were slightly off of what was optimal. This small flaw resulted in an increased risk of damage to the parts being washed and basket failure.

So, with this minor flaw having been identified, Marlin’s engineers adjusted the dimensions of the parts washing basket to reduce the risk of parts rattling loose during the wash process and getting damaged.

Naturally, part of the inspection process was to ensure that the revised dimensions for the parts washing basket would not cause a problem for loading or unloading the basket and its contents. After all, fixing a design flaw that could cause damage to the basket’s contents would do no good if the revised design kept the basket from fitting into the parts washing machine itself.

The customer was notified of the change and the reason for it, and the new basket design was approved.

Design Features of This Basket

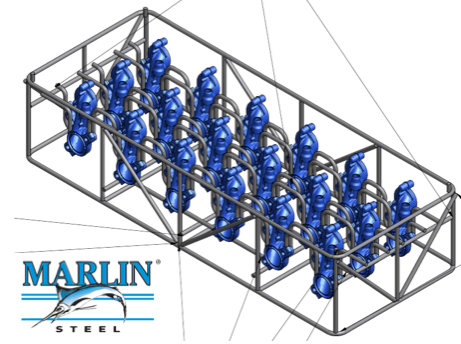

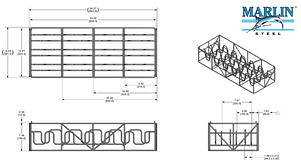

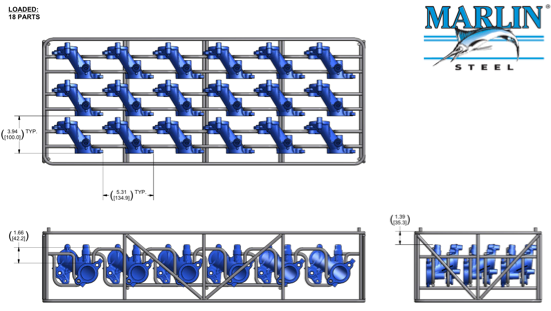

This basket, titled part #02016004, uses 43 different lengths of 0.313” thick grade 304 stainless steel wire. The basket is 34.01” long, 13.43” wide, and 7.48” deep, and weighs in at just under 20 lbs., making it one heavy-duty basket.

This basket, titled part #02016004, uses 43 different lengths of 0.313” thick grade 304 stainless steel wire. The basket is 34.01” long, 13.43” wide, and 7.48” deep, and weighs in at just under 20 lbs., making it one heavy-duty basket.

Why such a heavy duty design? The parts being held in this particular basket are large, complicated pieces, and the basket is meant to hold 18 parts at a time through the wash/finish process. On top of that, the baskets needed to be able to stack with one another, as well as the existing baskets. To help hold baskets in place, four small extrusions were set into the top of each basket to act as a guide.

By using thick grade 304 stainless steel, the basket benefits from both high corrosion resistance and superb tensile strength. The tensile strength of the basket is further boosted by using several crossbars and T-bars throughout the frame to reinforce it and prevent deformation when under heavy loads.

For this customer’s application, a natural finish was deemed sufficient to prevent corrosion, as grade 304 stainless is already highly resistant to corrosion. By using a natural finish, costs for the basket were kept down, keeping the design economical while still meeting the customer’s performance requirements.

Using advanced manufacturing robots, the Marlin Steel team was able to take the finalized design and put it into production with incredible consistency and precision. The end result was a fast delivery of an improved basket design that would meet the customer’s needs better than their old basket designs.

Learn more about how Marlin Steel can help you build a better custom metal basket for your parts washing and finishing processes today!

.gif)