Any manufacturer worth their salt wants to be able to improve their productivity. The faster you can manufacture parts and products, the better you can fill demand and the more revenue your company can generate.

Any manufacturer worth their salt wants to be able to improve their productivity. The faster you can manufacture parts and products, the better you can fill demand and the more revenue your company can generate.

The trick is in finding safe and effective ways to speed up your manufacturing process. One common area for improvement is in the parts cleaning/finishing process where you apply the final touches to make your products perfect for distribution.

So, how can you streamline your cleaning process while adding useful life to your products, rather than compromising them?

Here are a few ideas to get you started.

#1: Reduce the Number of Times Parts Have to be Manually Handled during Cleaning

One of the less obvious time sinks in a production process is the time that parts spend being handled manually.

Take, for example, moving parts from an ultrasonic cleaning basket to a high-temp resistant heat treat basket. During this process, production of parts is held up as workers have to manually move parts from one basket to the next. Then, when the specialized process is finished, the parts are frequently moved to yet another basket for the next phase of the process.

Take, for example, moving parts from an ultrasonic cleaning basket to a high-temp resistant heat treat basket. During this process, production of parts is held up as workers have to manually move parts from one basket to the next. Then, when the specialized process is finished, the parts are frequently moved to yet another basket for the next phase of the process.

Each time parts have to change baskets, time is lost. Worse yet, when moving delicate parts by hand, there is an increased risk of an accident where a part may be dropped or damaged by accident. For sensitive and expensive parts that need a flawless finish, this could ruin the part, or require extra time and effort repairing the finish. This can even hold up production for a whole unit, as the other parts of a product have to wait for that one ruined part to be replaced or repaired to make a whole product.

By finding ways to eliminate manual handling, you are optimizing your parts cleaning process and making it more reliable.

#2: Keep Parts Separated during Cleaning

One of the most common sources of damage to delicate parts, especially during ultrasonic cleaning, is from part to part contact. Two parts made from identical materials will, naturally, have the same hardness, meaning that they can easily scratch or damage one another.

When running parts through a cleaning process, using a parts washing basket or other container that can keep the parts separated greatly reduces the chances that parts will get damaged.

There are several ways to accomplish this, such as:

- Using a custom-shaped basket or container that holds each part in place.

- Adding dividers to a larger basket cavity to keep parts from directly touching.

- Washing just one part at a time in the wash process.

The first option does a great job of keeping parts in place, but restricts that container to use for that specific part or set of parts. Using dividers is a great option for keeping parts safe while maintaining flexibility, as the spaces can accommodate any part that will fit. The third option is the least practical, except when dealing with very large parts, which are less likely to be washed in groups anyways.

Not only will keeping sensitive parts that need to have pristine surface conditioning separated prevent scratching and other minute flaws, it can help to prolong the useful life of the part. How so?

Say that you’re manufacturing a small, delicate part that needs a perfectly smooth surface finish. Any flaws in the surface of this part could become a stress point later on, contributing to the failure of the part. By minimizing flaws, you prevent the creation of these stress points and increase the useful life of the part, as well as the satisfaction of the end user, who won’t have to replace the part as quickly.

One Easy Way to Do Both

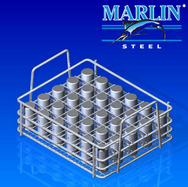

So, how can you reduce the number of times a part has to be manually handled and keep parts separated during the cleaning process? The easiest way is to use a well-designed custom steel wire basket that has been optimized to meet the demands of your parts washing process.

With the right basket, parts can stay in the basket as they’re moved from one phase of your process to the next, while custom wire fittings or dividers keep parts from rattling around and bumping together during even the most intense wash processes.

How can you get the perfect parts washing basket? Contacting an experienced precision basket manufacturer that serves high-demand industries is a good place to start. You can contact one of our expert engineers here.

.gif)