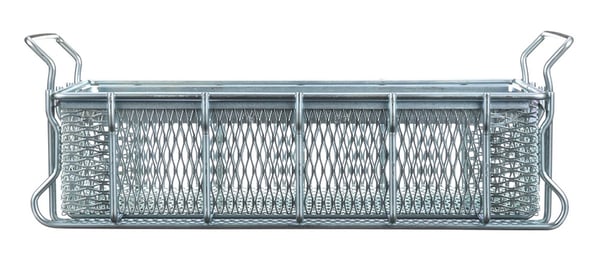

Expanded metal is sometimes considered an alternative to sheet metal or wire mesh. It combines some of the best features of both—providing a material that is stronger than thin wire mesh and has better air flow and drainage than sheet metal. In fact, it's an excellent option for custom wire baskets that need more tensile strength than wires can provide. Additionally, expanded metal cuts down on the need for extra welding operations compared to using individual steel wires, making it faster and easier to complete sturdy baskets.

Overall, stainless steel expanded metal baskets are incredibly tough and versatile—especially when made of highly-resistant metal alloys such as grade 316 stainless steel. They’ve got a variety of uses across just about every industry Marlin Steel works with and, for that reason, it’s worth exploring.

Quick Links

- What is Expanded Metal Mesh

- Expanded Metal Mesh Terms

- Measuring Expanded Metal Mesh

- Expanded Metal Mesh Uses

- Benefits of Expanded Metal Baskets

- Expanded Sheet Metal for a Custom Basket Designs

- Choosing The Right Stainless Steel Expanded Metal

What is Expanded Metal Mesh?

Stainless steel expanded metal mesh is made of a single solid sheet of compressed and stretched material. The expanded metal grating is useful for heavyweight custom parts washing applications, as well as providing open space for air flow and drainage.

Types of Expanded Metal Mesh

There are two distinct varieties of expanded stainless steel mesh used for baskets: standard and flattened. The term “standard expanded metal” refers to the metal as it comes out of the expanding machine. On the other hand, flattened expanded metal is what happens when standard expanded metal is put through a cold rolling steel mill to flatten the expanded stainless steel mesh.

How is Expanded Metal Made?

How is Expanded Metal Made?

How stainless steel expanded metal is made depends on the type.

In the process of making standard expanded metal, the expander and the sheet metal’s thickness determine the specific dimensions of the expanded metal, though thickness of the metal strands and the open space between them will be consistent and regular. Depending on the expanding equipment, standard expanded metal may have a slightly rounded appearance. This helps reduce any risk of wash process runoff collecting in the expanded metal basket.

Flattened expanded metal is put through a cold rolling steel to flatten the mesh. This makes the expanded metal grating thinner, flatter, and wider/longer. This type of expanded metal may have dimensions slightly different from any original estimates since it can be difficult to predict how much expansion will occur during the flattening process.

The choice between flattened and standard expanded metal mesh depends on the application. Standard expanded metal is often more useful for parts washing applications because the raised centers of the bonds prevent liquids from pooling in the basket. Flattened expanded metal, on the other hand, may be more useful for certain parts handling applications or for making larger custom mesh baskets slightly lighter by thinning out the metal mesh.

Expanded Metal Mesh Terms

Here is a brief list of useful stainless steel expanded metal terms:

- Strands. This is the term for the solid metal portions of the expanded metal grating. In the diagram at the top of the article, the strands are 0.107" wide.

- Bonds. This is the term for intersections of strands.

- Short Way of Design (SWD). The distance between the centers of bond strands in the mesh when measured along the short diamond diagonal. To illustrate this, in a diamond pattern shape like “<>,” the SWD would be measured from top to bottom. In the diagram above, the SWD would be approximately 0.372" (0.265" SWO plus 0.107" of strand thickness).

- Long Way of Design (LWD). The distance between the centers of bond strands in the mesh when measured along the long diamond diagonal. In a diamond pattern shape “<>,” LWD would be measured from right to left. In the diagram above, the LWD would be approximately 1.107" (1" LWO plus 0.107" of strand thickness).

- Short Way of Opening (SWO). The distance between the inside edges between bonds when measured across the short diamond diagonal. The difference from SWD is that SWO measures open space, while SWD measures the space from the center of one bond strand to the next. In the diagram above, the SWO would be 0.265".

- Long Way of Opening (LWO). The distance between the inside edges between bond strands when measured across the long diamond diagonal. Like with SWO, the difference between LWO and LWD is that LWO measures open space only, while LWD measures to the center of a bond strand. In the diagram above, the LWO would be 1".

- Strand Thickness. A measure of the thickness of a strand of expanded metal.

- Strand Width. How wide a strand of expanded metal is.

Measuring Expanded Metal Mesh

When measuring expanded stainless steel metal mesh, it’s important to consider the overall size of the metal plate after it is expanded, its long and short way of opening, and its strand thickness and width. This is because each of these factors will affect the basket’s performance.

For example, larger LWOs and SWOs mean the holes in the mesh are larger, which improves air flow for the expanded stainless steel mesh basket. On the other hand, thicker and wider strands tend to be stronger than thinner strands.

Comparing LWO and SWO against LWD and SWD helps to confirm the width of metal strands and overall open space of the mesh. For example, if the SWD and LWD of the mesh is 0.5” and 1”, and the SWO and LWO is 0.4” and 0.8”, then the width of the bond should be approximately 0.2” x 0.4”. This would provide a strand width of 0.1”. This would also create an open space of roughly 0.5 inches squared for each opening in the mesh.

Expanded Metal Mesh Uses

As noted above, stainless steel expanded metal mesh has a wide variety of applications across several industries. Some applications companies have used these incredibly tough and resilient baskets include:

Storage of Heavy Metal Parts

Several automotive parts manufacturers and companies in the aerospace industry have used stainless steel expanded metal baskets to hold their heaviest metal components as they were moved from one process to the next.

Why use grade 316 stainless steel for parts storage? In these cases, the baskets were doing more than just holding the parts—most steel alloys would have enough tensile strength for that. Instead, the baskets would often need to be able to withstand exposure to chloride-based solutions or salt-enriched air. Here, the superior chemical resistance of grade 316 stainless was needed to ensure the long-term viability of the basket.

Shot Peening Parts

Shot peening is the process of shooting parts with small particles of glass, metal, or ceramic to alter the part’s surface characteristics. Obviously, this kind of high-impact process is going to be incredibly stressful on the baskets holding the parts through the shot peening process.

Using expanded metal for the basket allows the particulates used in the shot peening process to reach the parts being modified, but gives the basket itself enough strength to survive repeated exposure to the process—unlike a steel wire basket, where a single wire might break from the impact.

Shot Blasting Parts

Shot blasting is a similar process to shot peening, but may use smaller particulates to not only change the surface properties of a part, but also to strip it clean of contaminants and/or to polish it. Here, grade 316 expanded metal baskets are useful because of their incredible durability, which makes them able to survive prolonged use in this high-stress application.

Degreasing Components and Brackets

Many vapor degreasing processes use incredibly caustic solutions that are heated to the boiling point to break up stubborn contaminants, such as machine oil/grease, and liquefy them so they can drain away from the part being degreased.

Grade 316 stainless steel can withstand exposure to the caustic solutions used in vapor degreasing and many other parts cleaning processes—making it the ideal material for this particular application.

Part Organization/Stacking

Heavy-duty grade 316 stainless steel expanded metal baskets are incredibly durable compared to their wire mesh counterparts. When created with a nesting or stacking design in mind, fully-loaded expanded metal baskets can be stacked to save space on the factory floor.

Many companies use this ability to stack baskets to help organize their finished parts as they await delivery or to dry off between processes.

Fire Safes for Warehouses

Some users of expanded metal baskets have used them as a kind of fire safe to protect delicate parts or papers in case of a warehouse or factory fire. When designed for this purpose, the expanded metal baskets are usually built in layers, featuring an open outer frame to keep heavy debris from impacting the sealed containers held within.

With its high melting point and a layer of insulation between the expanded metal frame and the sealed container held within, these baskets can be surprisingly effective at protecting delicate items from the fury of a blaze and the incidental impacts that may occur.

Benefits of Expanded Metal Baskets

Today, more and more customers are requesting expanded metal baskets. So, what are the main benefits compared to other basket types? Here are five of the benefits of using expanded metal baskets for parts washing and materials handling applications:

Today, more and more customers are requesting expanded metal baskets. So, what are the main benefits compared to other basket types? Here are five of the benefits of using expanded metal baskets for parts washing and materials handling applications:

1. Expanded Metal is Often Less Expensive

Sheet metal baskets are expensive because they use more raw materials than other basket types. Perforated sheet metal has less material in the final product, but that material has to be cut out in the first place, so costs (and material waste) are higher than expanded metal. Steel wire baskets use less material, but they require more welding to make them strong, so costs may be higher than what expanded metal baskets cost (depending on how many wires are involved, the type of welds applied, and other factors).

Why are expanded metal baskets often less costly? Because the plates used for the expanded metal are compressed and stretched out during the expansion process without wasting any material. This means, pound for pound, expanded metal will cover a larger basket area than sheet metal—and without the material waste of perforated sheet metal. The extra rigidity of expanded metal vs steel wires also means less welding is needed, so there is less time, labor, and money spent on welding.

2. Expanded Metal is Stronger Than Wire Baskets

With woven or welded steel wire, many weak individual wires are joined to create a basket. However, when the weight of a held part or material load falls on a particular wire, that wire has to support the weight by itself. Welding joins wires so the weight is distributed, but it isn’t as efficient as using a single, solid piece of metal to distribute the weight.

With expanded metal baskets, the expanded metal mesh is a single, solid piece of material that can efficiently spread out the weight of the materials it holds—making it able to take more weight than a wire mesh basket of the same general size, thickness, and open space.

Overall, expanded metal baskets are stronger than their steel wire equivalents—though not quite as strong as a sheet metal basket.

3. Expanded Metal Allows Good Air and Water Flow

Airflow is important for parts washing and finishing processes in manufacturing. If the airflow is restricted, parts may not get cleaned properly in the first place, parts may not dry quickly, and residue may be left from the washing process. This is one reason why steel wire baskets are a popular choice for parts-washing applications (particularly aqueous parts washing).

However, a close second choice for parts washing is expanded metal baskets. While the open space for an expanded metal basket isn’t as precisely controlled as for a wire mesh basket, they do offer plenty of open space between the strands of the metal to allow air or water to flow easily through the basket.

4. Expanded Metal Weighs Less Than Traditional Sheet Metal

Flattened stainless steel expanded metal has a flatter surface that may be better for materials-handling applications to help distribute weight or prevent parts from sticking to the expanded metal grating. When weight is an issue, flattened expanded metal is also lighter and slightly thinner.

5. Expanded Metal is Highly Durable

Because expanded metal strands are actually a single piece of material instead of a bunch of individual wires, expanded metal baskets tend to last longer than their wire mesh counterparts. The reasons for this improved longevity are twofold:

- The strands of expanded metal spread out impacts more efficiently than steel wires—reducing the effects of mechanical wear and tear on the basket.

- There are no welds to fail between the strands of an expanded metal basket—which further improves the basket’s durability compared to wire mesh.

While the difference probably shouldn’t be enormous between two well-designed and built custom baskets, the extra longevity of expanded metal can have a beneficial impact on the total cost of ownership over the years.

Why Should Expanded Sheet Metal Be Used for a Custom Wire Basket Design?

The applications listed above are just the start. One of Marlin Steel’s strengths is its ability to custom design according to the needs of a client, an industry, or an application. It’s why Marlin has patents on many of these designs, including USA Design patent # D860648 S and more. Understanding the numerous benefits to using expanded metal mesh for a custom basket design may help in the discovery of potential new applications. Expanded stainless steel wire baskets:

-

Provide better airflow than perforated sheet metal

-

Save money as it is less costly than sheet metal

-

Waste less material than perforated sheet metal

-

Are stronger than wire mesh

-

Weigh less than traditional sheet metal

-

Are easier to weld than wire mesh

For those reasons, expanded metal mesh is ideal for heavy-duty parts washing applications where sheet metal would prohibit air or fluids from flowing, but thin steel wires would not be strong enough to safely hold the parts.

Additionally, because expanded metal mesh is one solid piece of material, there’s no need to weld the individual strands together—which saves time and money on the manufacturing process while ensuring higher structural integrity.

Choosing The Right Stainless Steel Expanded Metal

The choice to determine which expanded metal grating to use will depend on your application. Since standard expanded metal has a slightly rounded surface, it may be more useful for part-washing applications where there needs to be no residue from runoff.

In comparison, flattened stainless steel expanded metal has a flatter surface that may be better for materials-handling applications to help distribute weight or prevent parts from sticking to the expanded metal grating. When weight is an issue, flattened expanded metal is lighter and slightly thinner.

It is important to note that if you’re working with flattened expanded metal, the LWO, SWO, LWD, and SWD measurements may vary somewhat depending on the direction that the metal was flattened. This introduces an element of variability that makes it harder to precisely control open space in the expanded metal basket. Flattening also makes the metal mesh thinner.

Standard stainless steel expanded metal mesh, on the other hand, has more consistent open space between strands—which is based on the machine used to expand the sheet metal.

Want to know more about expanded stainless steel mesh baskets? Reach out to the Marlin Steel team to learn more about the benefits of expanded metal mesh.

.gif)