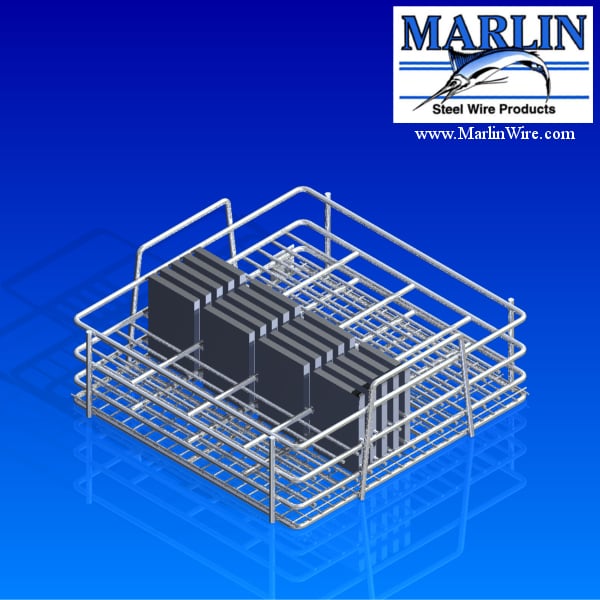

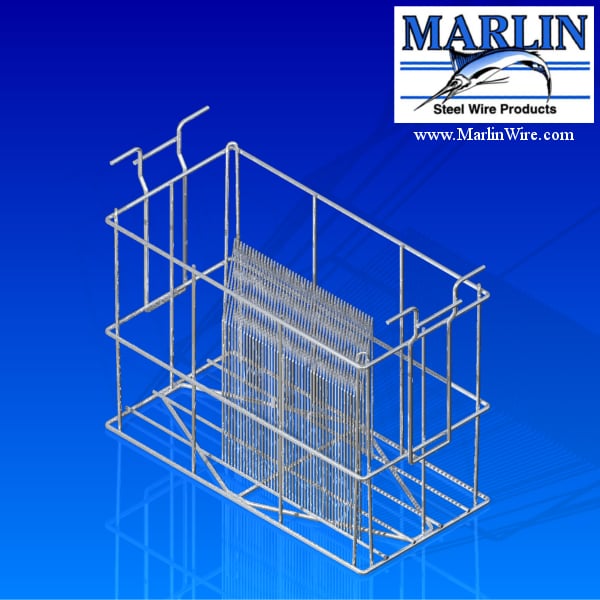

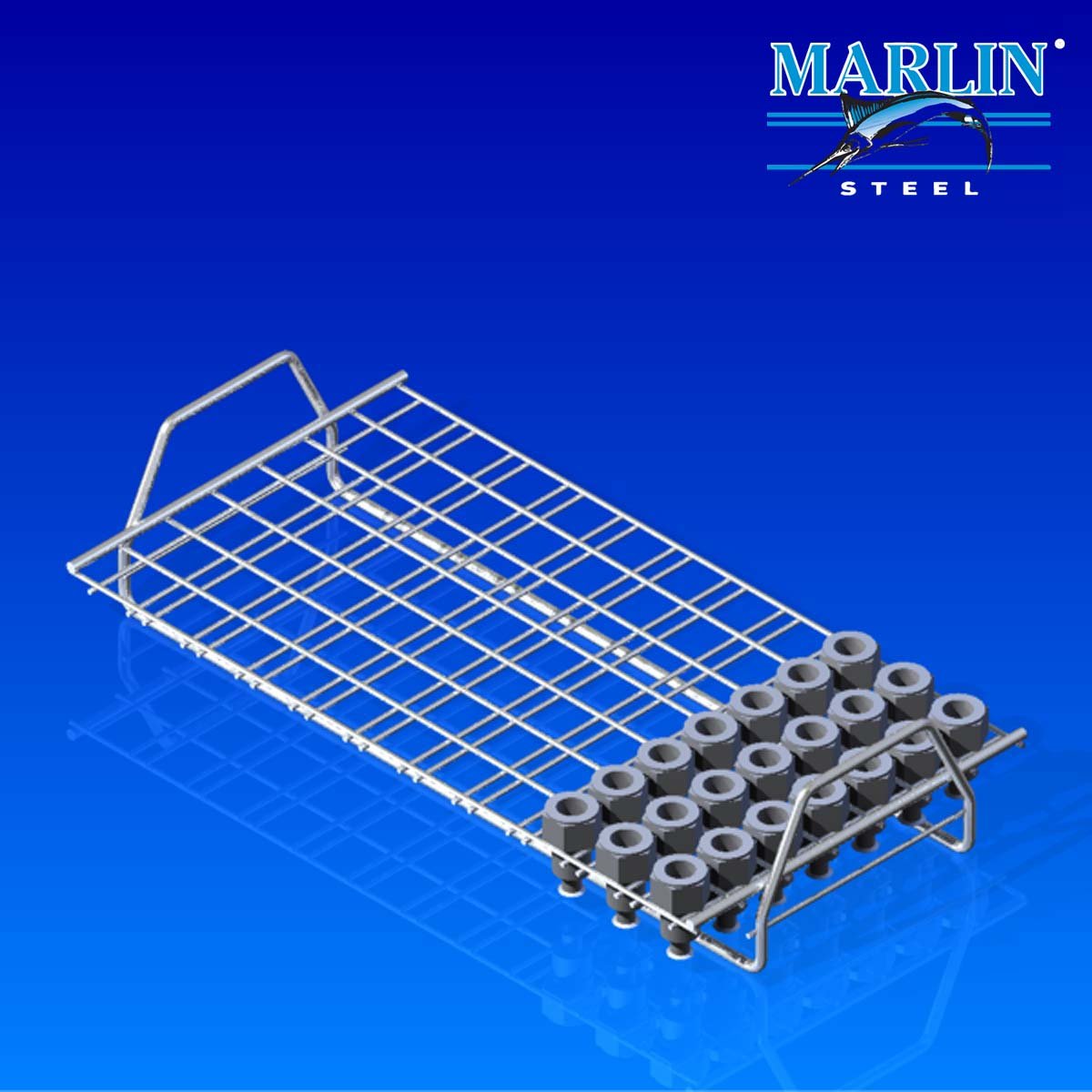

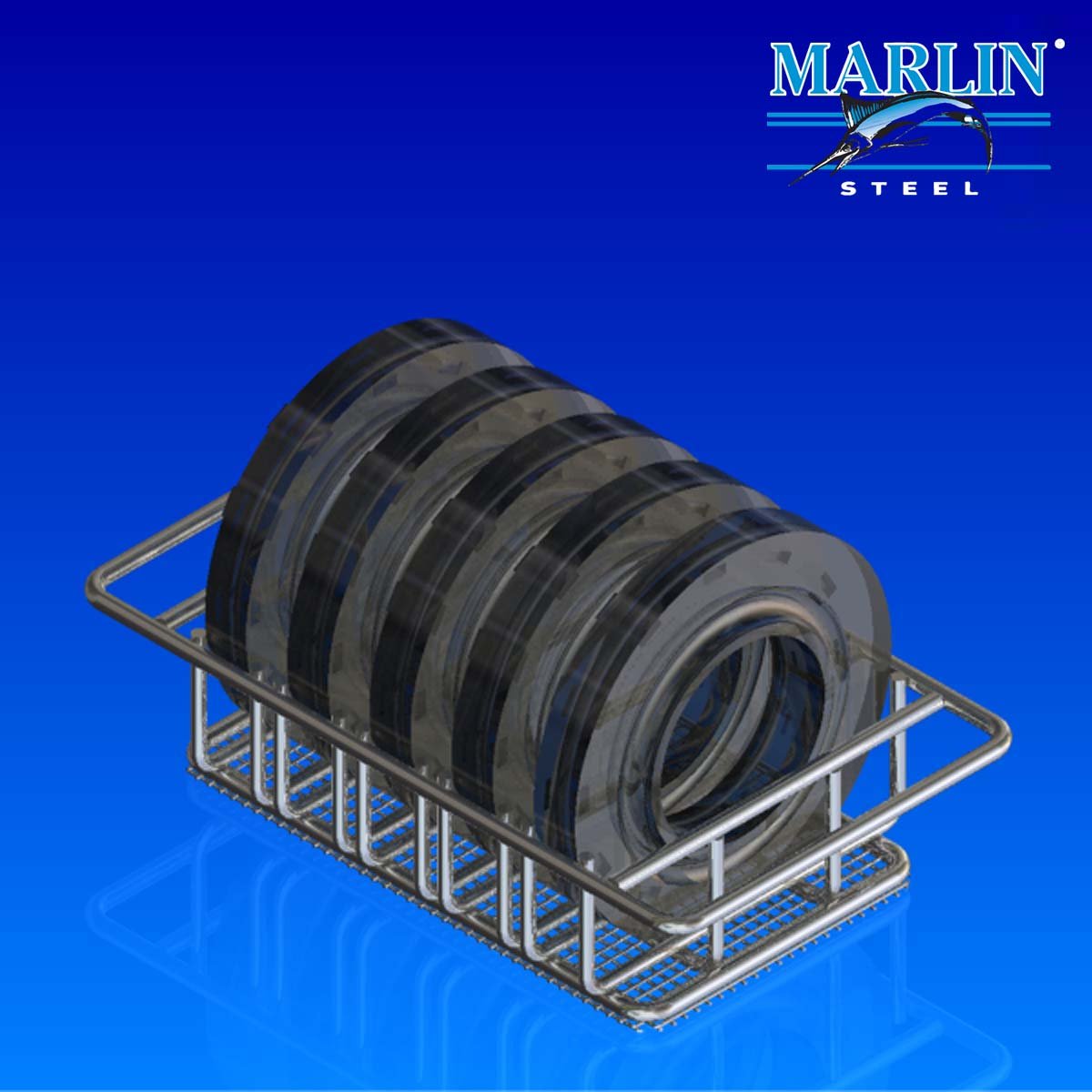

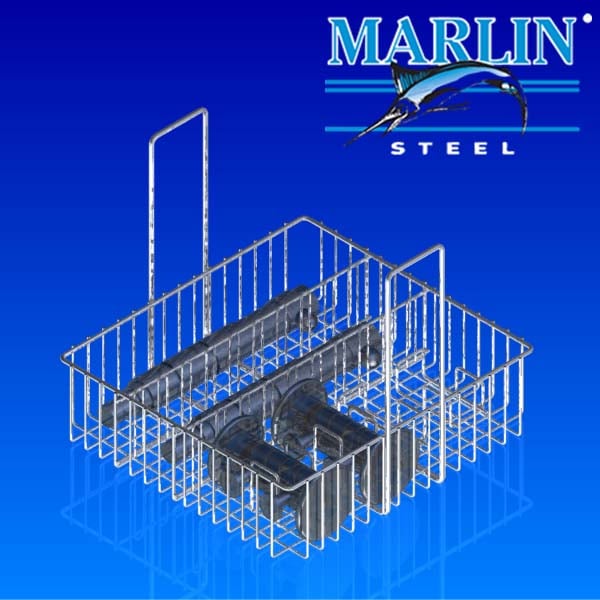

Since 1968, Marlin Steel has been a leading manufacturer of customized products made from sheet metal and steel wire. Regardless of your requirements, our experienced engineers can work with you to fabricate the ideal custom metal forms for your needs. With a strong commitment to innovation and engineering excellence, our expert team prides itself on providing Quality Engineered Quick®.

Overview & Advantages of Marlin Steel's Engineering Capabilities

With 10% of our team being degreed engineers and our ISO 9001:2015 certification, Marlin Steel has a full range of engineering capabilities, providing our valued clients with the following advantages:

Comprehensive Engineering Services

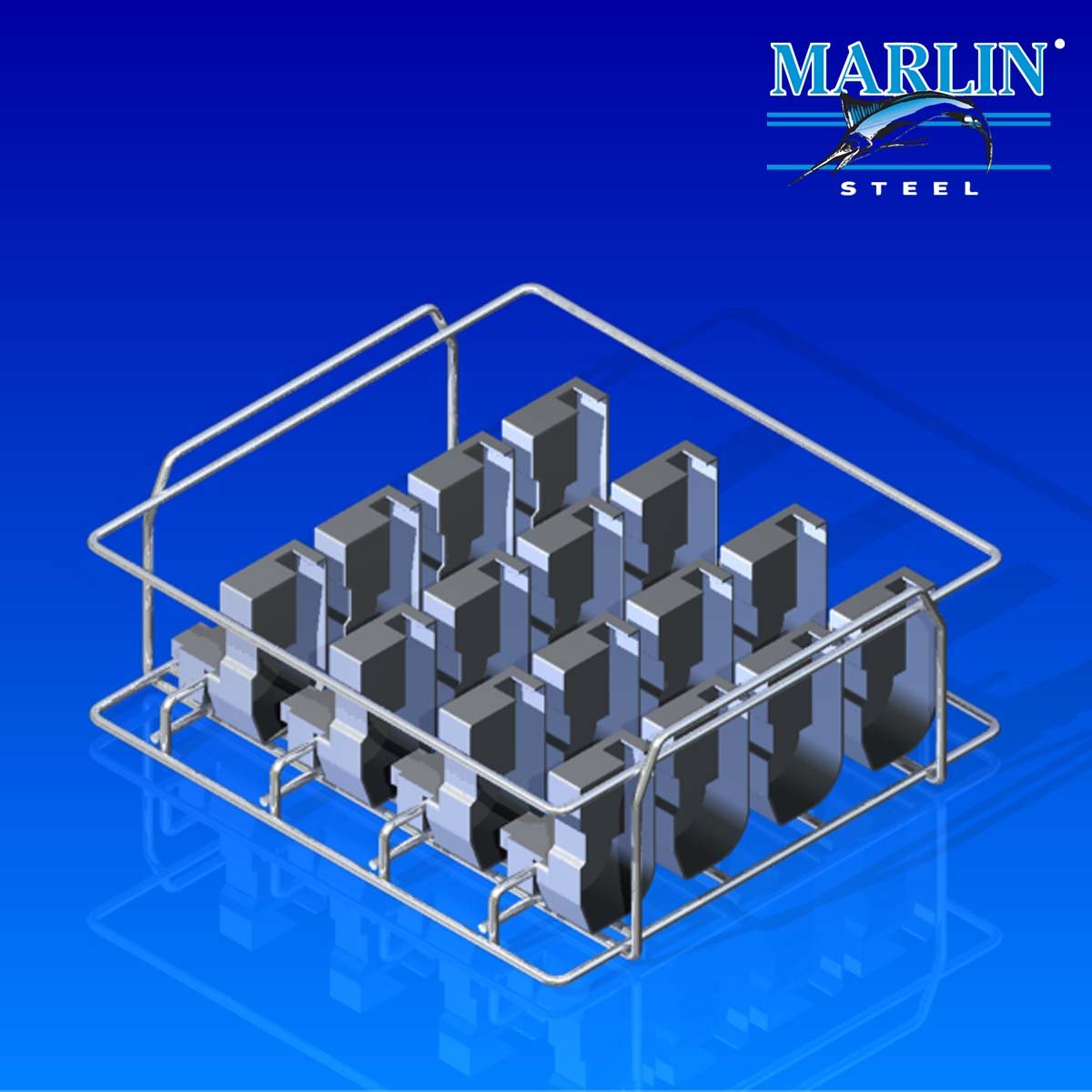

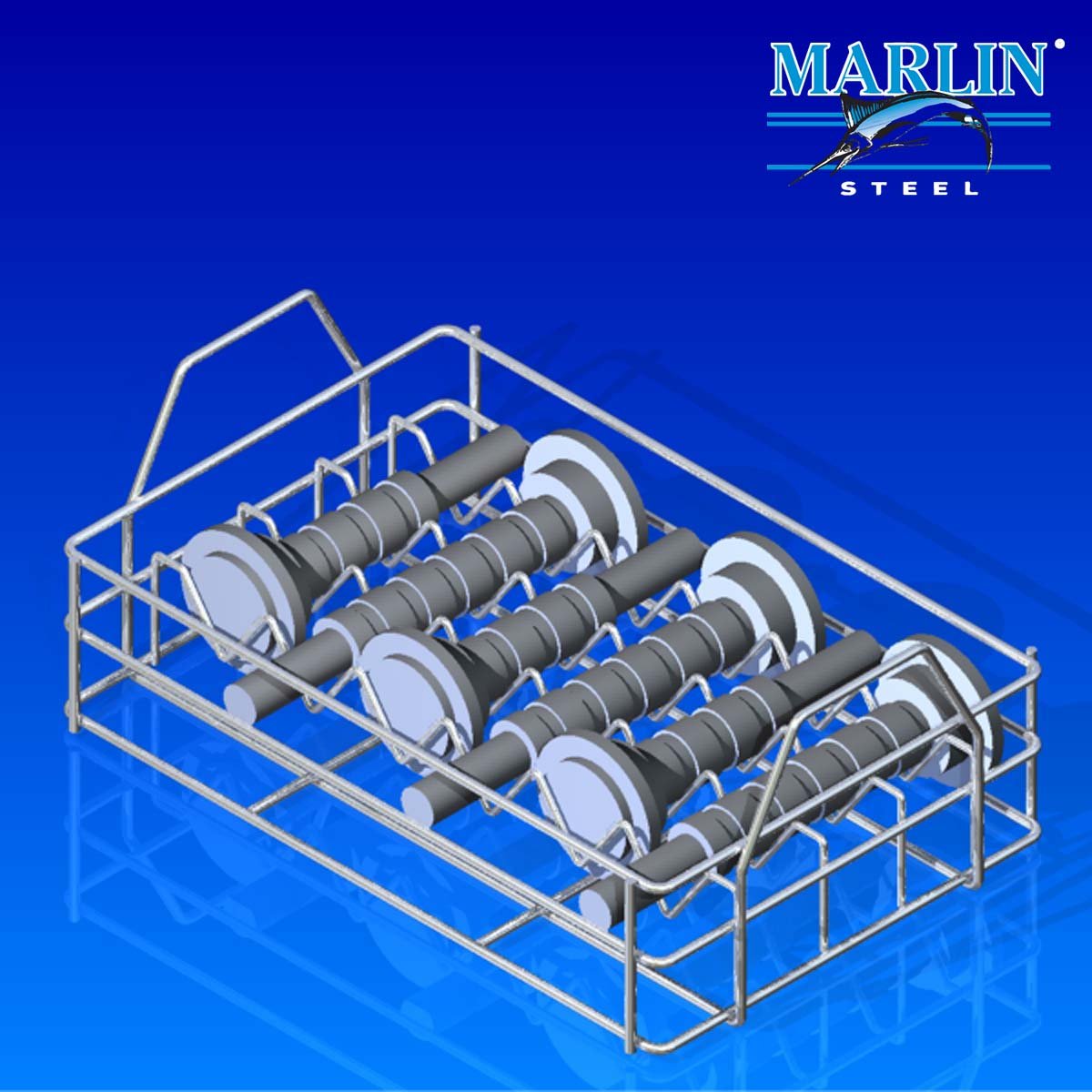

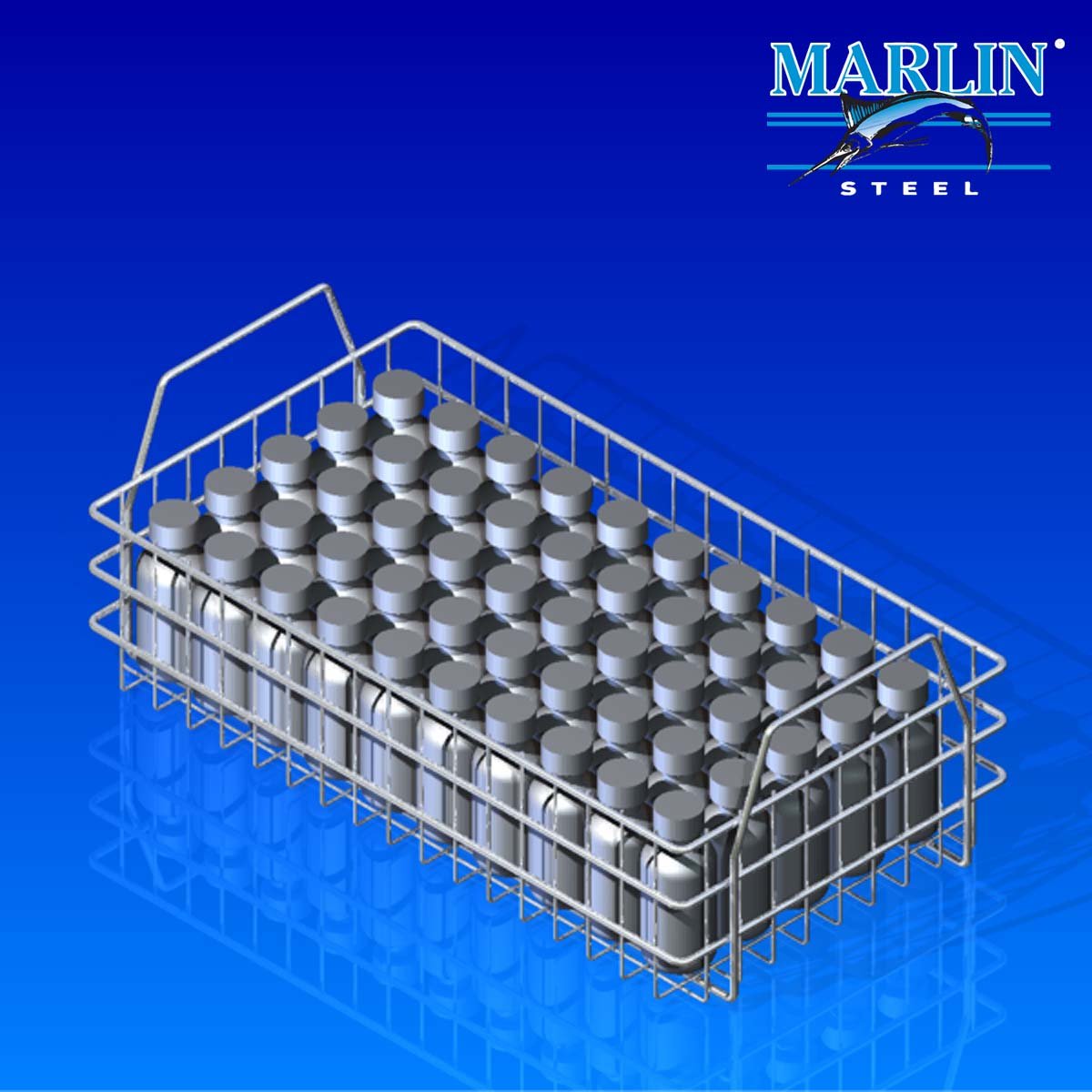

At Marlin Steel, we provide our clients with detailed prints and innovations to solve their engineering challenges, resulting in a significant return on investment in their facility operations. Our comprehensive range of engineering services helps our clients achieve:

- Improved workflow

- Enhanced cleaning processes

- Reduced scrap

- Improved safety practices

- Reduced costs

Client-Centric Approach

Before design work begins, our team must understand the attributes and scope of the proposed project. Providing our clients with a custom basket questionnaire supplies our engineers with the information they need to grasp the form, fit, and function requirements. At Marlin Steel, we work closely with our clients to dial in the right solutions, even making factory visits, to ensure project success.

Proven Success in Diverse Industries

Marlin Steel serves a diverse range of industries, some of which include:

- Food Processing: Marlin Steel is a prominent force in the food processing industry, shipping approximately $5 million of food processing racks annually.

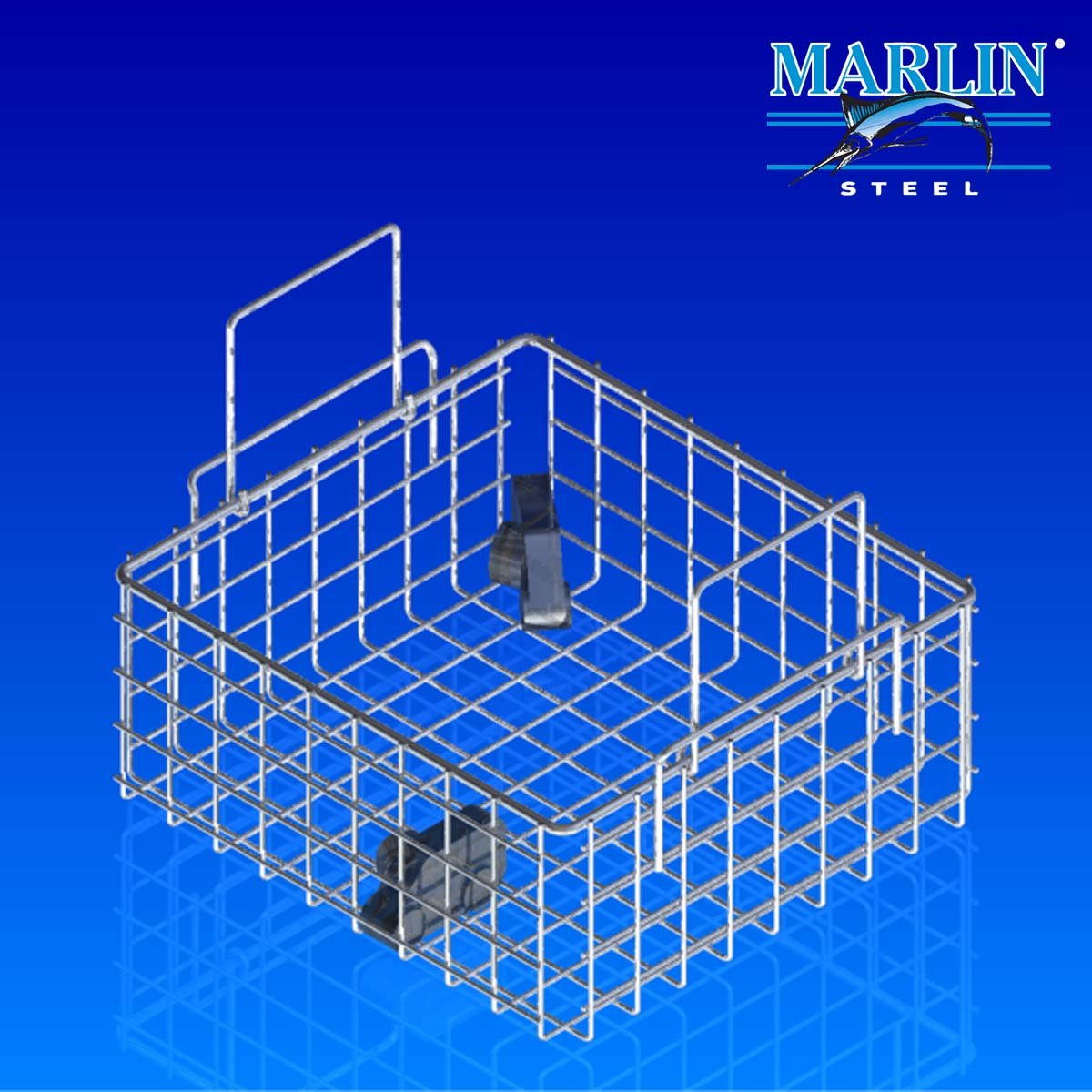

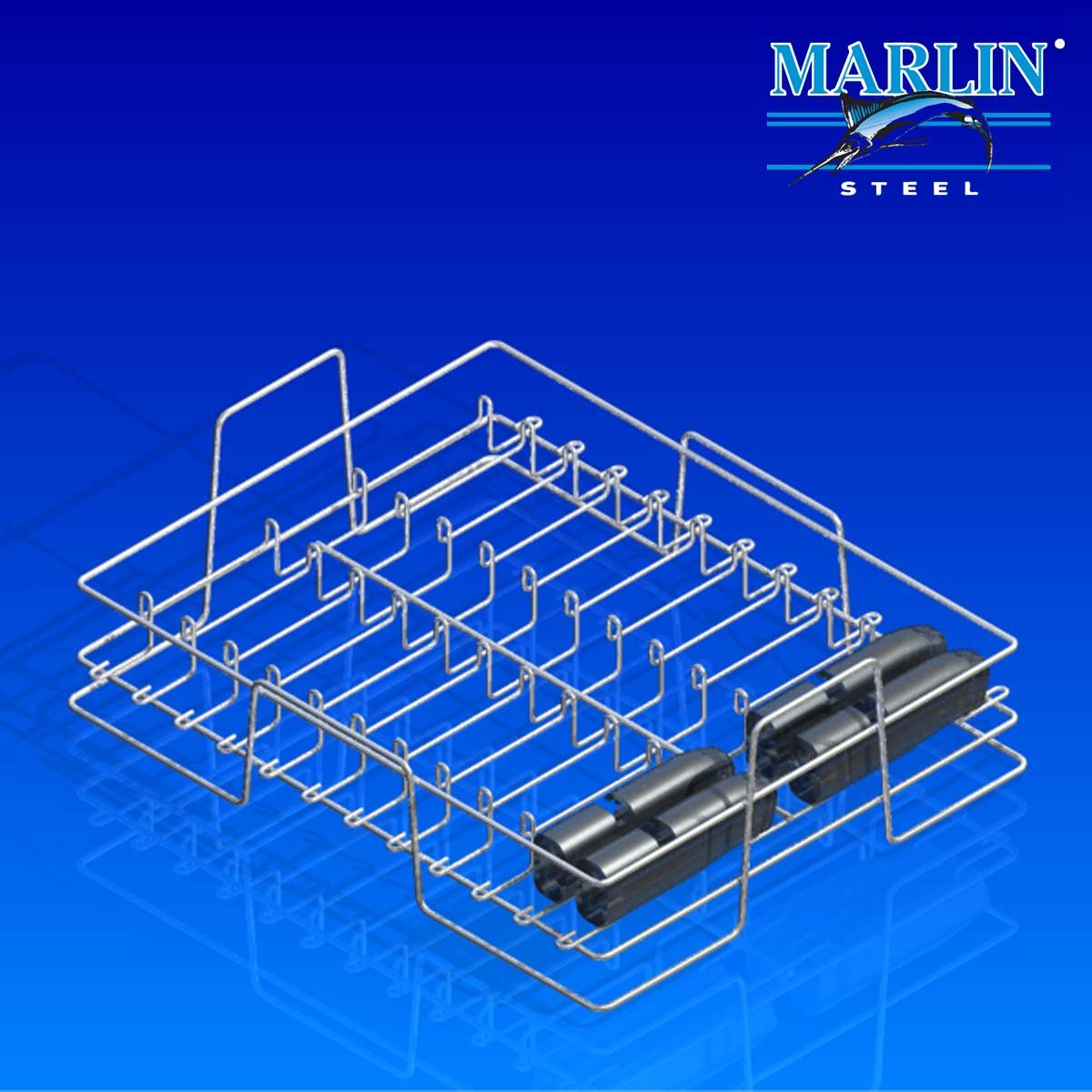

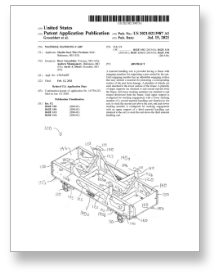

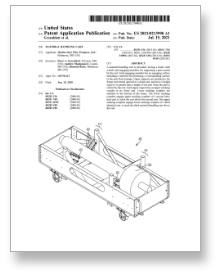

- Aerospace: Our aerospace racks, baskets, and wire forms carry several patents and represent a rapidly growing sector at Marlin Steel.

- Automotive: We are committed to quality and compliance.

- And more

Uncompromising Quality Assurance

Throughout every phase of manufacturing, our quality team meticulously scrutinizes each component and assembly. We are ISO-certified and employ precise fixtures to ensure uniformity, quality, and adherence to tight tolerances.

Cutting-Edge Tools and Technology

The Marlin Steel engineering team utilizes AutoCAD Inventor Software, which allows for seamless work in .DXF and .STP formats. This helps to ensure compatibility with various engineering workflows.

Streamlined Development and Prototyping Process

After client approval, Marlin Steel engineers create release prints that fully detail each process step for developing individual parts and components. The use of precise fixtures to constrain parts guarantees uniformity, and we can provide overnight samples for test fit checks before production starts.

Tailoring Solutions for Unique Challenges

At Marlin Steel, our highly experienced degreed engineers bring innovation and solutions, drawing on concepts from high-end projects produced for industry giants. Each custom solution incorporates refined elements derived from similar applications.

Unmatched Expertise and Capabilities

Marlin Steel has degreed engineers allowing us to deliver comprehensive solutions for a wide range of applications. We provide detailed prints with impeccable clarity and exhaustive details that include the following specs:

- Front view

- Top view

- Isometric view

- Side view

- Weld legends

- Tolerances

- Materials

- Finishes

Our prints provide process and manufacturing engineers with clear direction on how the part will be made. Marlin Steel stands out among the competition in expertise and capabilities, producing impeccable solutions that meet a client's fit, form, and function challenges.

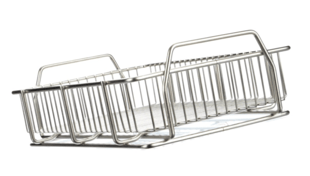

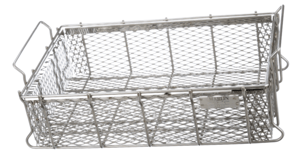

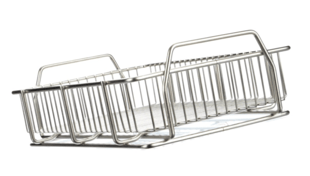

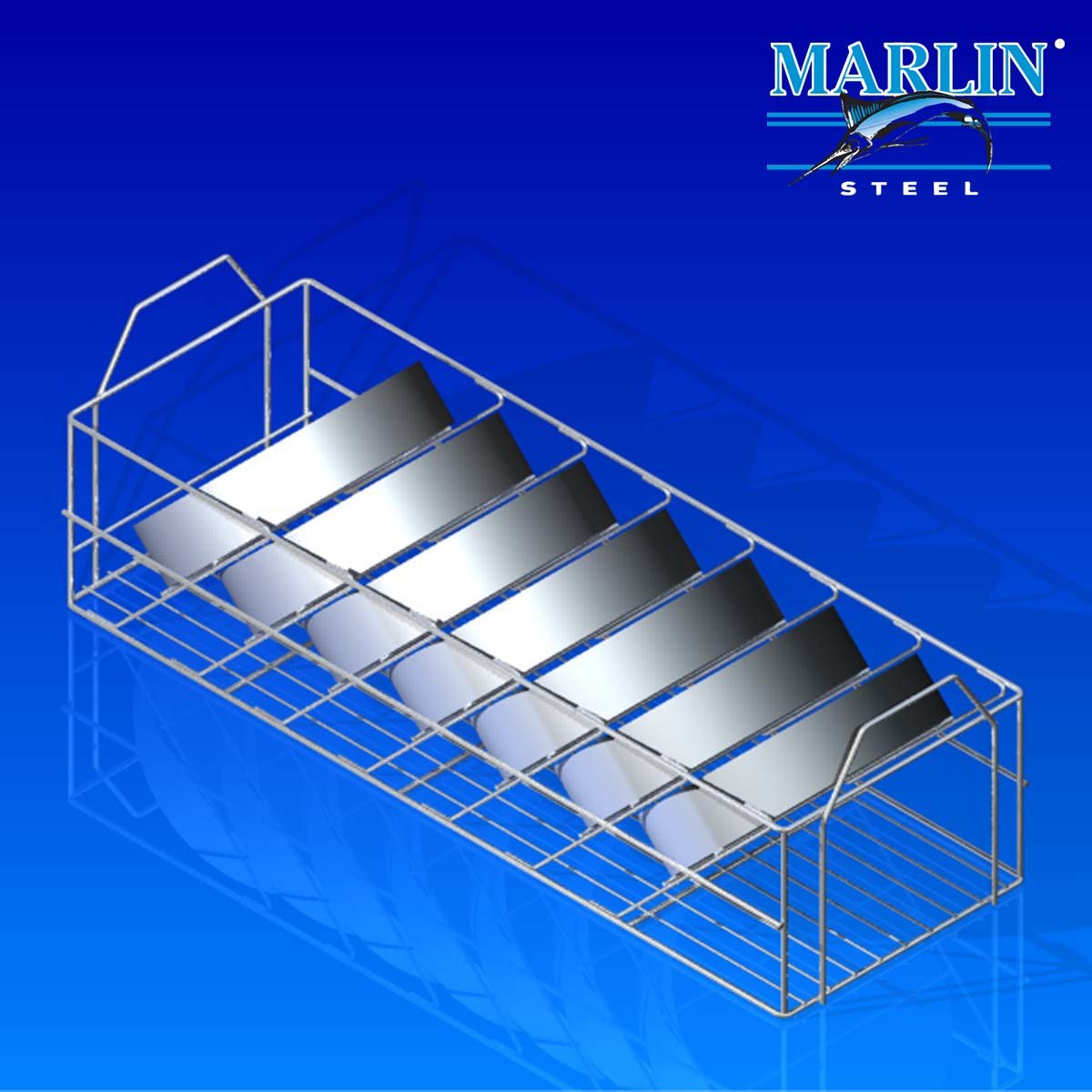

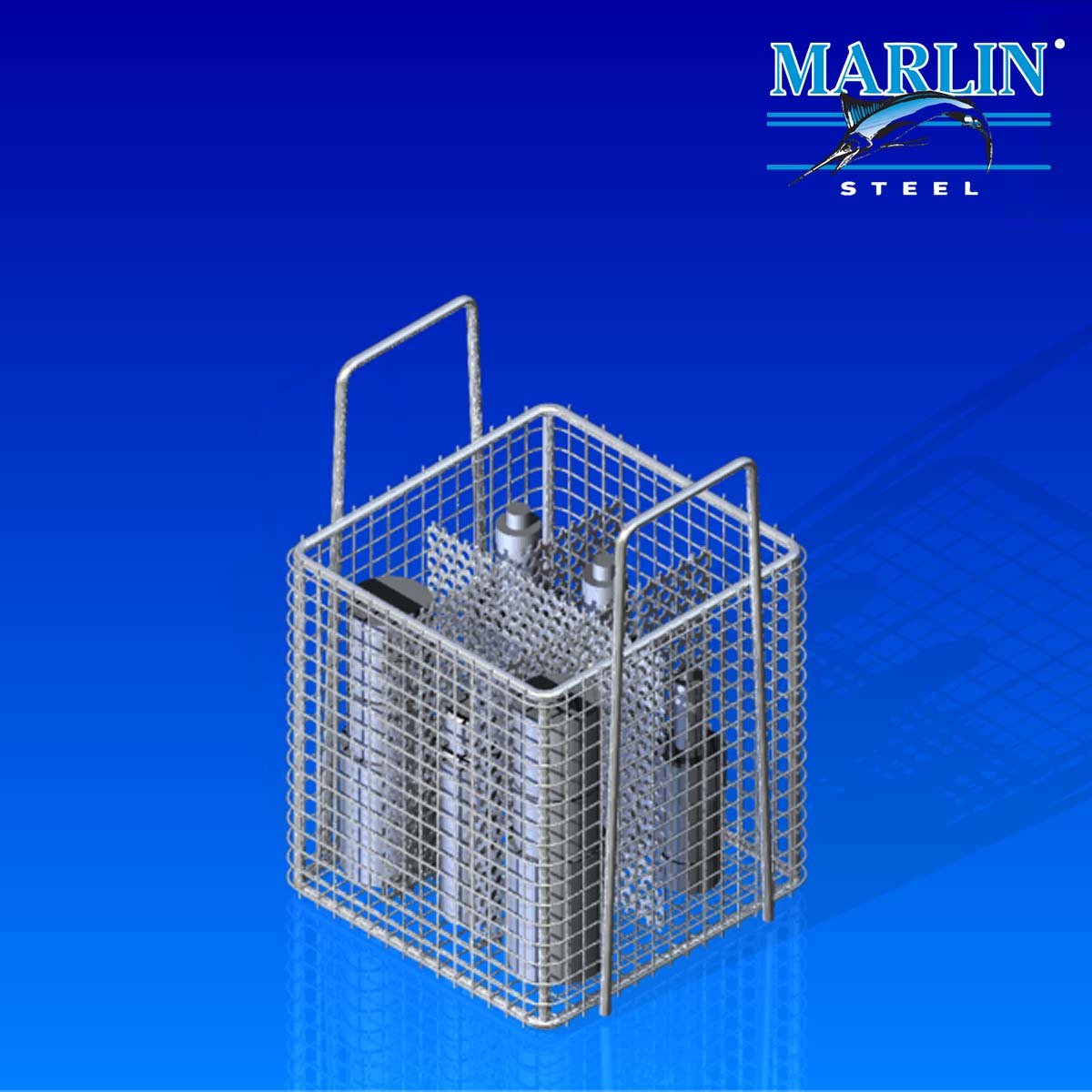

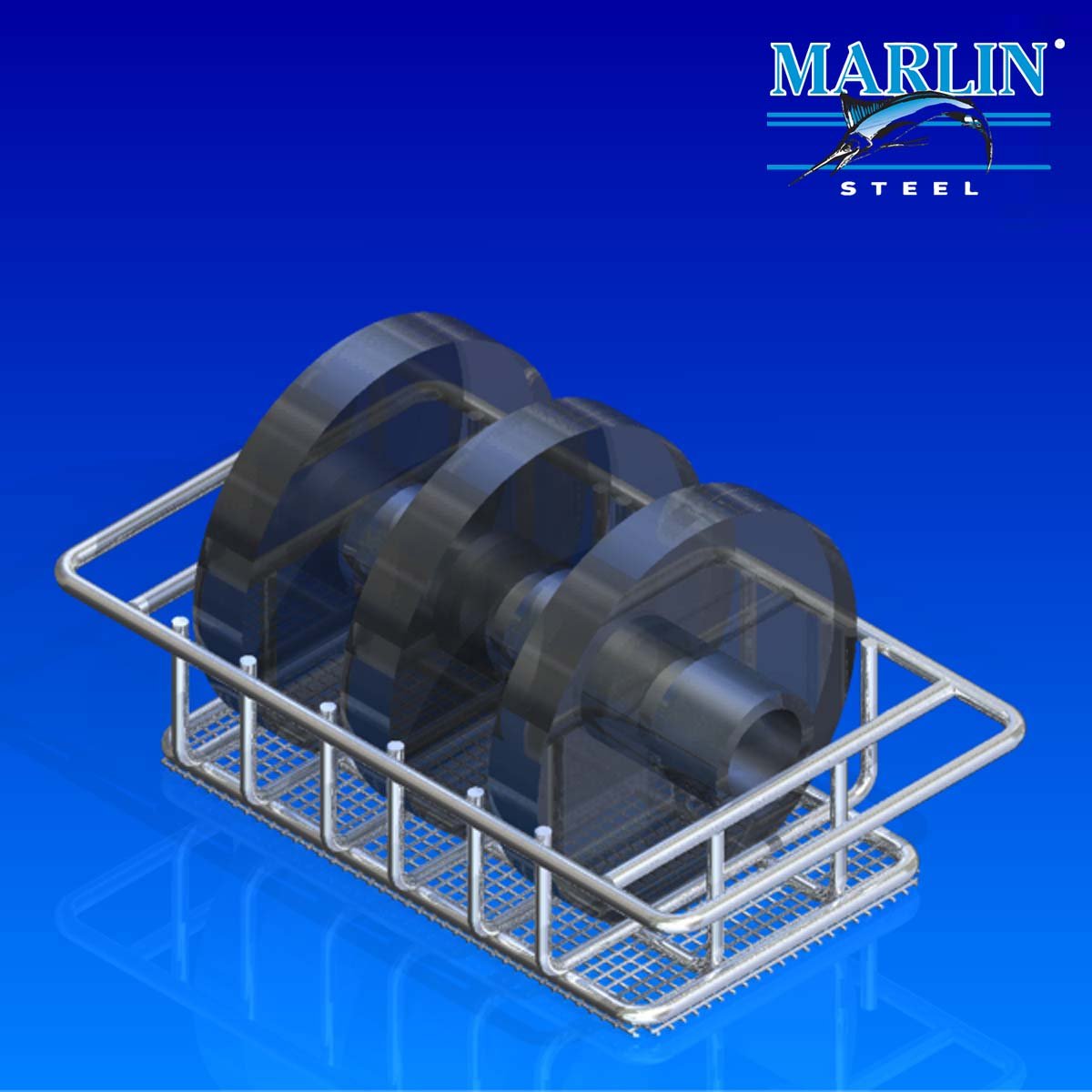

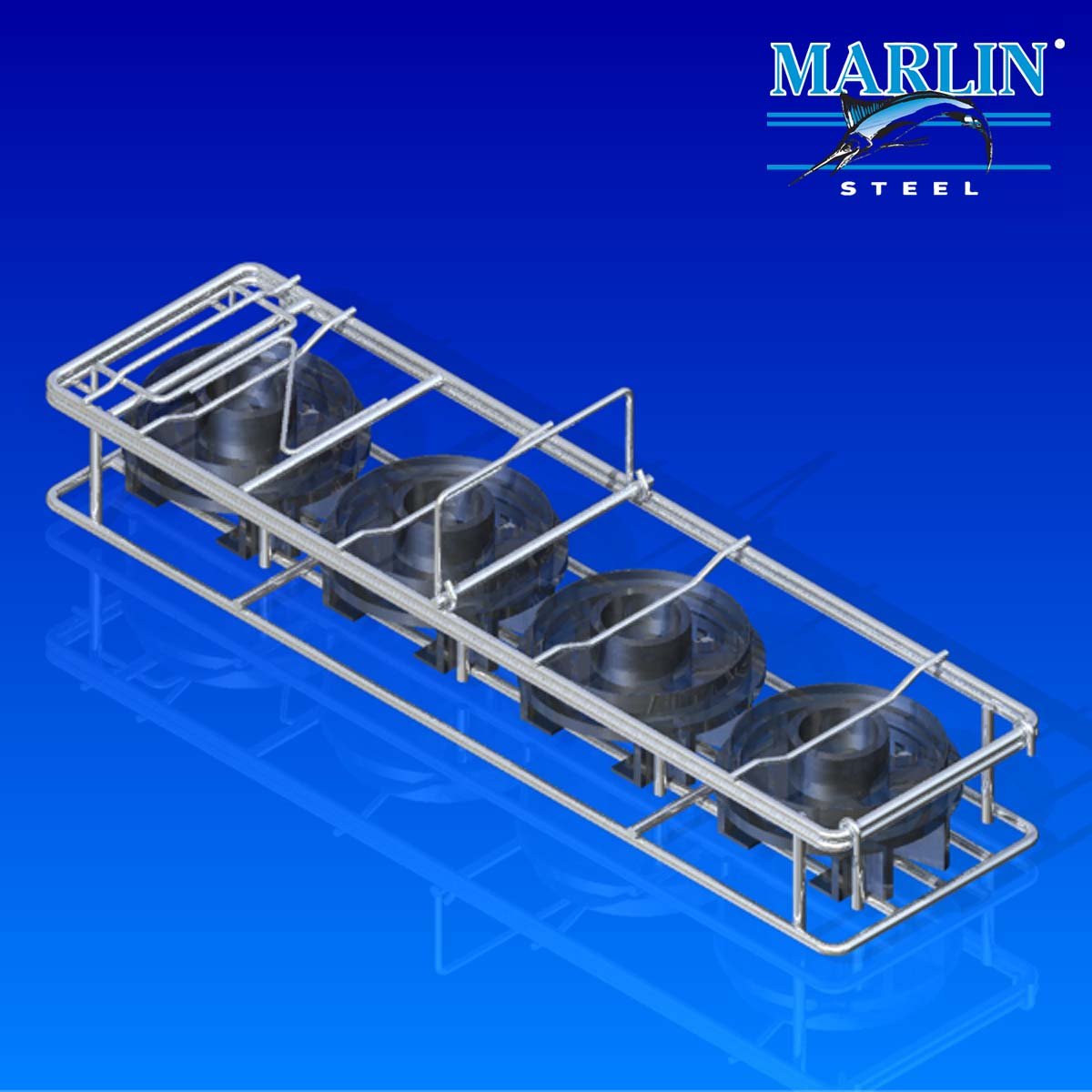

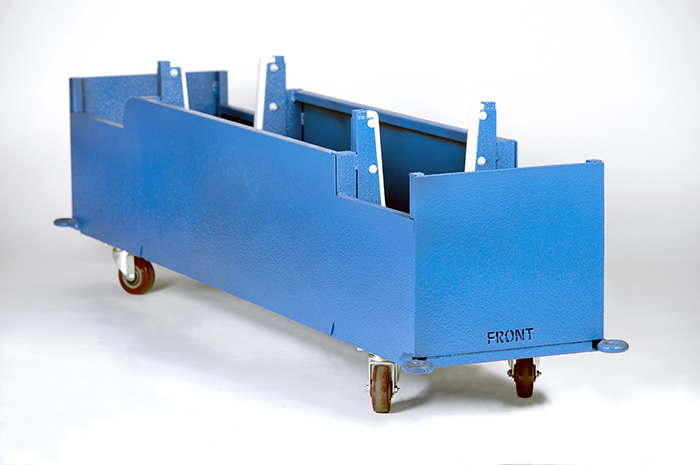

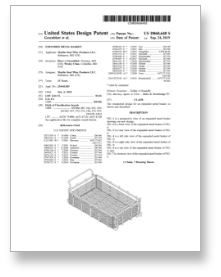

Novel Innovations – Our Patented Solutions

Marlin Steel engineers work hard every day to create industry-leading innovations, as evidenced by our six patents. In addition to the patents listed below, we have several more pending:

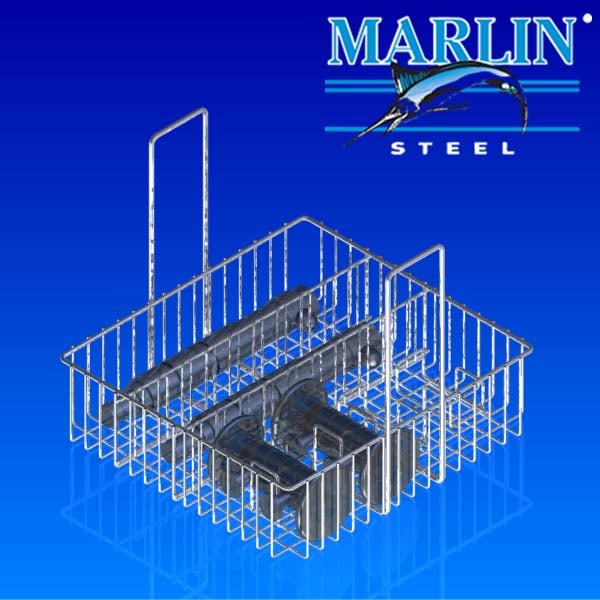

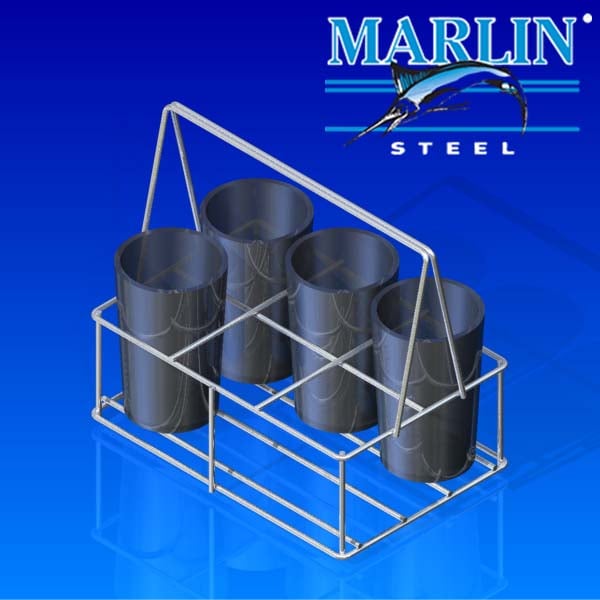

-1.webp?width=2000&height=1953&name=02320003-101-02-04-1%20(6)-1.webp)

-1.webp?width=2000&height=2000&name=02320003-101-02-04-1%20(2)-1.webp)

.webp?width=2000&height=1953&name=02320003-101-02-04-1%20(6).webp)

.webp?width=2000&height=2000&name=02320003-101-02-04-1%20(2).webp)

.jpg?width=2000&height=2000&name=circular%20float-1%20(1).jpg)

-1%20(3).jpg?width=2000&height=2000&name=02320003-101-02-04-1%20(2)-1%20(3).jpg)

.jpg?width=270&height=270&name=00837016%20(1).jpg)

.jpg?width=270&height=270&name=02016004%20(3).jpg)

-1.jpg?width=270&height=270&name=00938016%20(1)-1.jpg)

-1.webp?width=456&height=456&name=00-00363279-38-01-01%20(1)-1.webp)

.webp?width=456&height=456&name=00-00363276-14-01-01%20(1).webp)

.webp?width=456&height=456&name=00-00363279-38-01-01%20(1).webp)