Medical and Pharmaceutical Baskets, Racks, and Trays

Custom Steel Wire Forms for Medical and Pharmaceutical Applications

Custom Steel Wire Forms for Medical and Pharmaceutical Applications

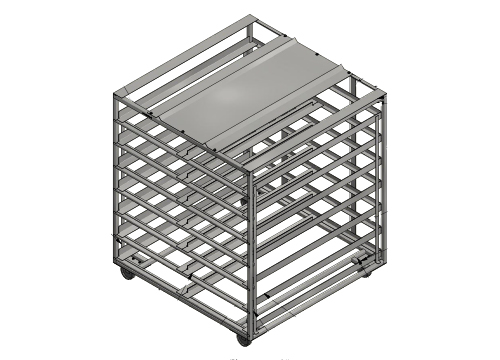

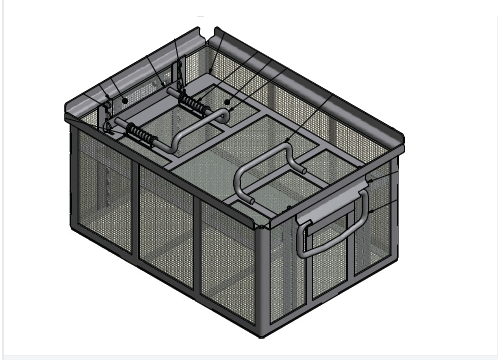

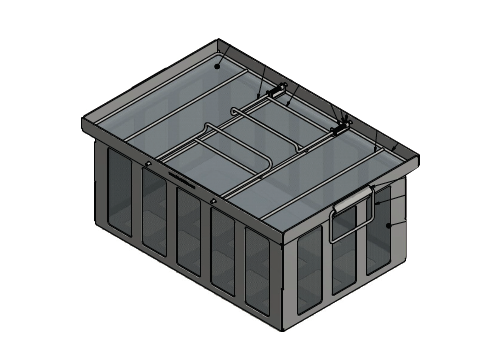

We manufacture stainless steel products for the medical and pharmaceutical industry, including a range of sanitary carts, trays, baskets, and equipment. These products can be electropolished to provide a microscopically-smooth surface for even more efficient sanitation. This electropolishing makes it incredibly easy to ensure cart/tray/basket sterility from one operation to the next.

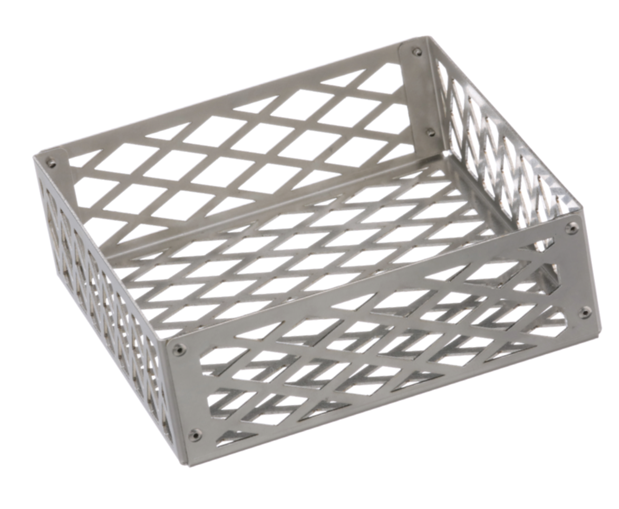

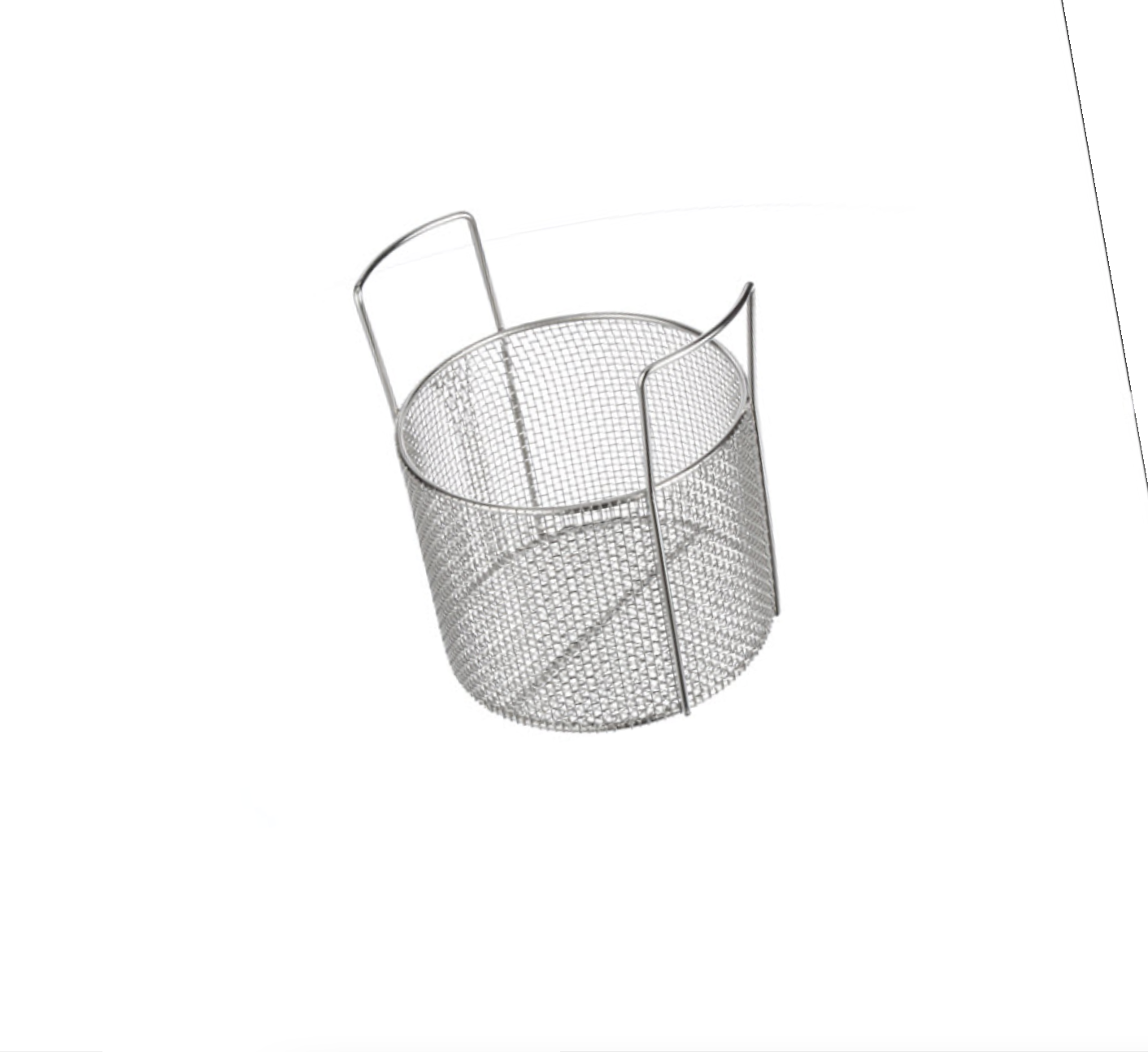

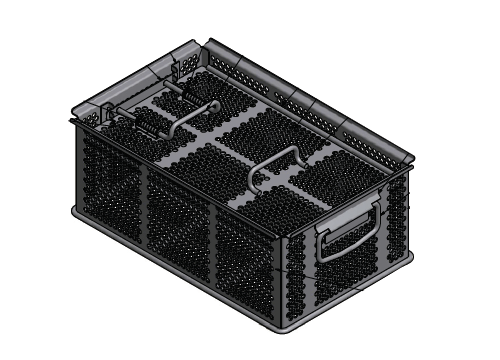

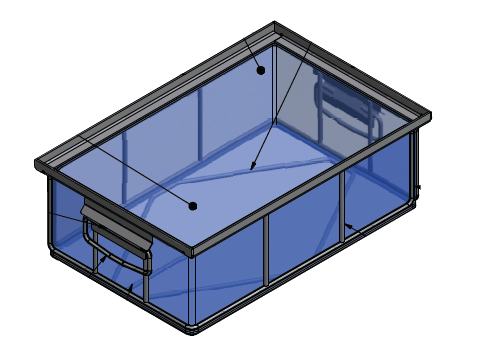

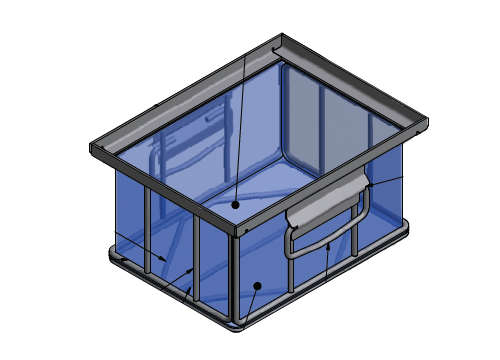

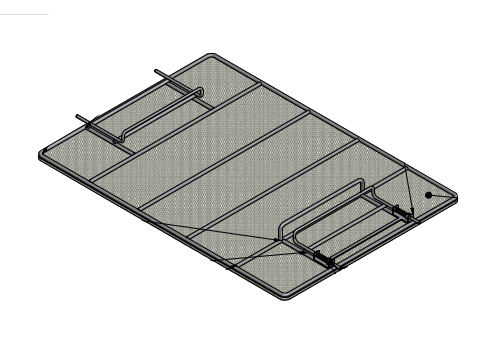

Here are some of our stainless steel wire, basket, and tray products, made from grade 304 and 316 stainless steel, that assist with a wide variety of medical and pharmaceutical procedures. If you have specific requirements for your wire form tray or wire form baskets, Marlin Steel’s team can create a custom wire form specifically for your needs.

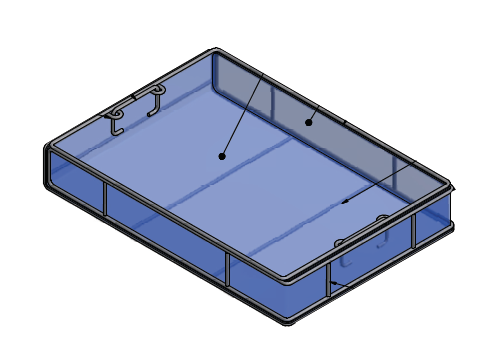

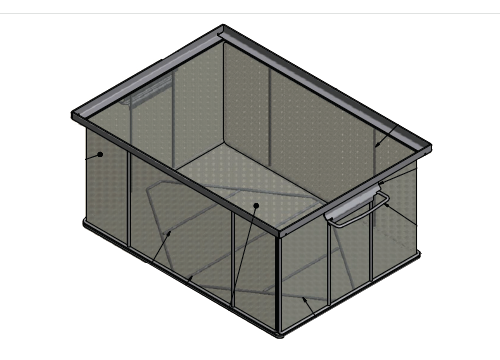

The right stainless steel medical trays can protect delicate medical instruments during parts cleaning and enhance the sterilization process. Whether in a hospital room, lab, or surgical theatre, stainless steel medical trays are cost-effective, durable, hygienic, and both temperature and corrosion-resistant. For example, Marlin Steel’s stainless steel medical instrument trays can be moved efficiently between processes, whether by hand or conveyor belt, and can be electropolished to ensure sterility.

Other medical tray applications include:

Whether you need an ultra-fine woven mesh basket to hold delicate small parts or a stackable frame for storage, Marlin Steel’s baskets and surgical steel wire forms help pharmaceutical and medical products meet their stringent standards for sanitation and sterility. The corrosion resistance properties of medical grade stainless steel make these products stronger than alternatives, such as plastic, and more resistant to damage.

Essentials for Disease Control

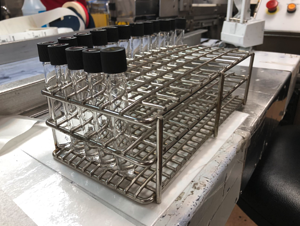

Essentials for Disease ControlMarlin Steel proudly manufactures products for infectious disease control, including ventilator parts, PPE, test tube racks, shields, and goggles.

During the COVID-19 pandemic, Marlin Steel’s degreed engineers created stainless steel test tube racks for a large healthcare provider to assist with viral testing, as highlighted by the Washington Post.

Marlin Steel Wire Products LLC does not use any animal-derived materials such as BSE/TSE, melamine, or latex in the manufacturing of our products. Marlin Steel products are made exclusively of Stainless Steel 304 grade or 316 grade material and then electropolished.

There are numerous benefits of custom wire forms for medical and pharmaceutical applications. Medical grade stainless steel is highly corrosion-resistant, which makes it ideal for applications with corrosive chemicals, such as blood, salt, and cleaning agents. The inherently sterile nature of stainless steel and the sanitation benefits of electropolishing, make this high-quality metal quintessential for pharmaceutical and medical environments.

When compared to alternatives, such as plastic, medical grade stainless steel has numerous advantages, including:

Where plastic may absorb contaminants and allow them to spread, steel is non-absorbent and allows for better sanitation control. When electropolished, those attributes are enhanced. Additionally, stainless steel can take extremely high temperatures without getting damaged.

Stainless steel is highly durable and stronger than alternatives. Even the “softest” stainless steel alloys are many times stronger than plastic. Further, stainless steel tends to resist scratching, handle drops, and withstand high temperatures far better than alternatives. Further, its corrosion resistance means chemicals will not compromise medical grade stainless steel.

A well-made stainless steel surgical tray will outlast cheaper alternatives and provide consistent protection to delicate and small medical parts that could be expensive to replace if damaged.

Stainless steel is incredibly easy to reuse and recycle compared to most polymers. Where plastic may end up in the dump or the ocean as pollution, steel can be re-used in countless other products with ease.

Medical grade stainless steels, like grades 304 and 316, are highly formable and offer durability and corrosion resistance. Grades 304 and 316 stainless steels have a chemical composition that includes high levels of nickel which make them resistant to extreme temperatures and receptive to sanitation. As a result, they’re highly suitable for the strict demands of the medical industry.

Cotter pins are a common tool for fastening objects that you may need to quickly disassemble later. In pharmaceutical and healthcare applications, ...

Read More >>

Medical and pharmaceutical product manufacturers and users both have to be very careful about how they store and wash their tools. Manufacturers need ...

Read More >>

Doctors, upon receiving their first white coats, take an ethical oath to their patients. Often that oath is misquoted as including the phrase “First, ...

Read More >>

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797