We do more than stock products. Contact us to see how our customization capabilities can help.

Marlin Steel fabricates custom sheet metal, wire forms, wire racks, and wire baskets using robotic welding processes. Our advanced capabilities deliver "Quality, Engineered Quick®" for an international customer base. Using the appropriate welding process is a key part of delivering the best services to our customers.

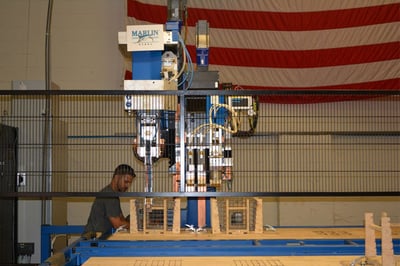

Our factory floor features numerous machines for robotic metal inert gas (MIG) welding, also known as gas metal arc welding (GMAW), and robotic tungsten inert gas (TIG) welding, also called gas tungsten arc welding (GTAW). Together, these machines enable us to provide our customers with efficient, high-quality metal fabrication services to their specifications.

Marlin Steel offers 100% USA Made galvanized wire bucket handles with plastic grips in a variety of sizes and shapes that can be purchased in bulk. We ship out of Maryland and Michigan.

Robotic welding offers several key advantages that manual welding services don't offer, including:

Tungsten inert gas (TIG) and metal inert gas (MIG) welding are the most popular welding methods today, but you must choose the right technique for your application. Marlin Steel can help determine which type of robotic welding method to use based on your needs. The right selection ensures that your component can withstand the stresses of its application.

To help select the ideal welding method, we use a virtual physics simulation tool to confirm the reliability of the end product's welded joints. The result will be a reliable, high-performance product using high-quality materials.

For example, we can use medium frequency direct current (MFDC) robotic welders to form wire baskets and racks according to customers’ unique specifications. Robotic TIG welding often works best for wire basket and rack products because it's optimal for joining thinner metal pieces. Robotic MIG welding is compatible with thicker metal pieces. Generally, TIG welding is best for intricate products where aesthetics are important, while MIG welding is best for heavy-duty welds.

Ultimately, choosing the right method for your project will depend on the compatible materials, specifications, and budget of your project.

Depending on our customers' needs, we use two main types of robotic welding systems to fabricate various metal sheet, wire, basket, and rack products.

This TIG and MIG welding machine model has a 1,100-pound capacity for parts, with the positioner moving in sync with the machine's welding robot arm. It also features a laser touch sensor system that automatically positions the workpiece and all welds in the correct locations.

This model is among the world's most technologically advanced robotic welding machines. It can complete each weld in just two milliseconds with high precision and consistency.

Marlin Steel’s Robotic Welding SpecsWhether your application needs robotic MIG or TIG welding, Marlin Steel can help select the right method for your custom metal welding solution. When you work with Marlin Steel, you’ll receive 100% USA-made products of the highest quality, delivered quickly. We are also ISO 9001:2015 certified, which ensures that we provide consistently high-quality solutions for all customers while meeting strict regulatory standards.

To learn more about our robotic welding solutions or to get started on a project with us, contact us today.

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797