Doctors, upon receiving their first white coats, take an ethical oath to their patients. Often that oath is misquoted as including the phrase “First, do no harm” though the actual text reads “I will do no harm.” The sentiment is, essentially, the same. However, more recently many take a different kind of oath, one that calls on a more far-reaching goal of total care for a patient, including to prevent disease. Why does this matter? Because it’s about ethics and values.

That’s why Marlin Steel takes seriously the medical and pharmaceutical applications of its products. We understand that doctors, hospitals, medical equipment manufacturers, and pharmaceuticals are operating on those principles and, as a supplier of products for their industry, Marlin shares those goals. So, when the medical or pharmaceutical industries present a need, it’s the job of the Marlin team to deliver.

Quick Links

- Why You Should Choose Stainless Steel Trays for Medical and Pharmaceutical Applications

- 8 Uses for Stainless Steel Medical Trays in both Medical and Pharmaceutical Industries

- Case Study: Building Steel Trays for Pharmaceutical Power Washing

- Case Study: Building Steel Trays for a Medical Implant Manufacturer

- Let Marlin Steel Meet Your Stainless Steel Tray Needs

Why You Should Choose Stainless Steel Trays for Medical and Pharmaceutical Applications

When considering the importance of the application and the risks associated with bacterial infections in a hospital setting, it’s essential to provide materials that can adhere to the stringent hygienic standards set forth by medical and pharmaceutical industries. While many associate stainless steel with cleanliness due to its prevalence in industries with strict health codes, there are actually a lot of reasons stainless steel is ideally suited for these industries.

In short, it’s versatile and durable. Its elemental make-up, high chromium and nickel and low carbon, means it can be molded or cut into just about any shape you need. Its surface is remarkably hygienic and easily disinfected while being scratch- and corrosion-resistant. It’s affordable, cost-effective, and recyclable. These characteristics, above all other metals, make it the best option for environments that must adhere to strict industry standards in regards to cleanliness, but also value functionality, durability, and product longevity.

8 Uses for Stainless Steel Medical Trays in Both Medical and Pharmaceutical Industries

1: Autoclave Sterilization Pouch Holders

Stainless steel wire trays are often used to hold autoclave pouches through the sterilization process. The high durability and increased temperature resistance of stainless steel make these trays ideal for faster autoclave processes that require higher temperatures.

2: Hospital Overbed Tables

Stainless steel medical trays are often used in conjunction with hospital bedside tables or overbed tables to hold patient meals, medicines, and other items. The ease of sterilization for these steel surgical trays makes them easy to reuse over and over for patients for years. Further, their durability and cost-efficiency make them an excellent choice.

For some patients, having a tray they can grab from their medical bed table is simply more convenient than trying to move the whole table into position—which improves convenience for the patient as well.

3: Surgical Instrument Trays

Stainless steel trays are often used to hold surgical instruments during procedures. The fact that stainless steel (especially electropolished steel) is so easy to clean and can resist oxidation from exposure to blood and other bodily fluids makes it ideal for holding sterile tools. Further, because of its properties, stainless steel medical trays are easier to clean to maintain strict hygiene standards set forth by medical regulators and hospital standards.

4: Medical Sample Storage & Handling

Stainless steel surgical trays can be used to hold medical samples for study, and to sterilize the sample trays after they’ve been used. Again, because of the ease of cleaning, the oxidation and temperature resistance, and the durability, stainless steel trays are incredibly versatile, whether in a patient room, a surgical theatre, or a lab.

5: Holding Medical Implants Through Cleaning Processes

Because bacterial infections are so dangerous, particularly post-surgery, hospitals and medical product manufacturers need to ensure that medical implants used in patients are free of any and all contaminants. So, they often use stainless steel medical trays to hold their medical implants through cleaning processes and during the implant surgery.

Pharmaceutical Uses

Marlin Steel has made custom wire trays and baskets for this very purpose for major medical manufacturers and, much like the medical industry, the pharmaceutical industry has multiple applications for stainless steel trays as well.

1: Product Sterilization Processes

Pharmaceutical companies often have to thoroughly sanitize their products or their containers to ensure sterility and safety. Stainless steel wire baskets and trays are an excellent choice for carrying or holding products and containers through both chemical and temperature-based sterilization processes.

In fact, the chemical resistance of most stainless steels make them long-lasting in such processes (particularly grade 316 stainless), while their high temperature tolerance means they can handle temperatures that would melt plastic sterilization trays.

Further, electropolishing the stainless steel eliminates microscopic surface flaws that could otherwise house microbes. Because sterilization is so crucial to much of the medical industry, stainless steel is often the best route to go.

2: Pharmaceutical Manufacturing Equipment

To help ensure sterility, many pharmaceutical manufacturers use electropolished stainless steel for their manufacturing equipment. The microscopically-smooth surface of electropolished stainless steel is incredibly resistant to corrosion and easy to clean, making it ideal for pharmaceutical manufacturing.

3: Cryogenic Storage Containers

Austenitic stainless steel alloys are noted for excellent performance at low temperatures. As noted by AZO Materials, “At cryogenic temperatures the tensile strengths of austenitic stainless steel are substantially higher than at ambient temperatures. They also maintain excellent toughness.”

This makes austenitic stainless steel alloys excellent for cold storage or cryogenic preservation equipment. However, this only applies to austenitic alloys, such as grade 304, 316, or 317 stainless steel. As AZO Materials states, “Ferritic, martensitic and precipitation hardening steels should not be used at sub-zero temperatures. The toughness of these grades drops significantly at low temperatures.

Case Study: Building Steel Trays for Pharmaceutical Power Washing

In any manufacturing application, fast and efficient parts washing is crucial as it impacts productivity. However, In the pharmaceutical industry, parts-washing procedures have to be both efficient and thorough. Otherwise, the manufacturer risks parts contamination that could render the medical instruments unsuitable in a sterile environment.

One medical instrument manufacturer recently reached out to Marlin Steel to create a set of stainless steel medical instrument trays to hold their parts through a high-pressure washing process that used hot water to blast surface contaminants off the parts and sterilize them.

The Challenge of Making Medical Instrument Trays for Pressure Washing

One of the biggest challenges in this stainless steel medical tray project was ensuring that the parts wouldn’t be blasted out of the tray by the pressure washing process. Small, delicate parts could be easily knocked around or even out of a shallow stainless steel tray if the enclosure had no top and, again, keeping parts sterile is paramount.

By using a heavy wire mesh lid, the mesh allowed the high-pressure water jets to pass through while keeping parts secure. By using electropolished grade 316 stainless steel, we ensured the product would be resistant to water corrosion and any corrosives that might be present on the medical instruments being cleaned by the client.

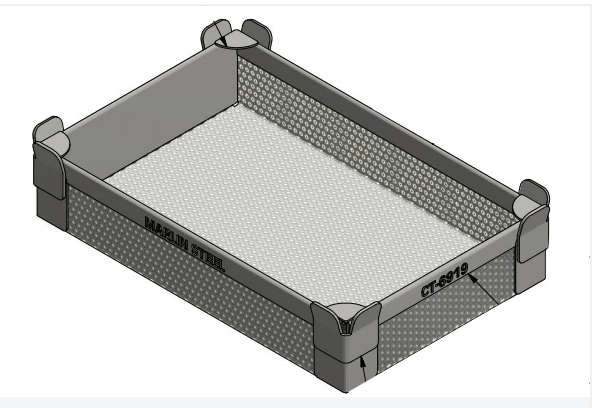

The bottom and sides of the medical instrument trays also use stainless steel wire mesh to allow water and air through the tray while keeping held parts inside. To accommodate a variety of instruments, no dividers or wire patterns were included; the interior remained open.

To keep the wires of the medical instrument trays easy to clean and free of corrosion after repeated use in hot water, they were made of stainless steel. Because of how strong stainless steel wires are, they could be made incredibly thin without impacting the tray’s ability to withstand the pressure washing process.

Testing the Medical Instrument Tray

While the stainless steel tray should have been able to withstand the client’s parts sterilization/washing process, a flaw could cost the client time and money, so testing was important.

Marlin ran the basket through finite element analysis (FEA) software to test it in a virtual environment. With FEA software, years of use could be tested virtually in minutes—without committing a single piece of wire to a physical prototype.

If the basket failed the test, the cause of the failure would be automatically noted so that we could correct that flaw. Because of the detailed report and the speed of the test, our team could evaluate multiple iterations of the tray in hours. Compare this to physical prototype testing, which could take weeks to move from version A to version B.

Thanks to Marlin’s use of FEA software, our team was able to perfect the stainless steel medical trays for the client in two days and move to full-scale production without wasting time or materials. This sped up the delivery of the finished trays—helping the client stay on schedule for its own production.

Case Study: Building Steel Trays for a Medical Implant Manufacturer

The consequences of a contaminated medical or surgical implant are significant and dangerous. While the operation itself may be compromised and the hospital held responsible, the patient might also experience chronic inflammation, or worse, at the surgical site. Therefore, medical implant manufacturers often obsess over the sanitary conditions of their manufacturing process. From initial assembly to the final assembly/packaging, everything must be meticulous.

So, when a medical manufacturer called Marlin Steel for a parts handling tray for their medical implants for femur assemblies, including cannulated screws, hitting the standards set by both the Marlin team and the medical manufacturer was crucial.

Keeping it All Together

One of the biggest challenges for this job was that under no circumstances could any part fall out of the tray and hit another surface. Yet, at the same time, each part had to be easy to access for handling in a precise layout.

The need for easy access precluded the use of a lid or total wire mesh enclosure since both of these structures would impede access. Instead, each tray would fit up to three units high inside of a separate catch basin to trap fallen parts.

This, along with the inclusion of handles, would help ensure the trays would be easy to handle throughout the wash process and in between other processes.

Stacking for Efficiency

Because handling a single tray of parts would be an inefficient way to process these parts, the tray was made to be stackable. Not only did this help maximize productivity, but it afforded plenty of clearance between each layer of parts. As a result, more parts could be moved and processed simultaneously and the extra space facilitated drying after the aqueous wash/sanitation process was completed.

Encasing for Sanitation

The capture bin for the trays served a dual purpose—during the wash process, it would capture fallen parts so they wouldn’t hit the floor. Once finished, the bin would enclose the trays on all but two sides (top and front) thereby limiting the exposure of parts in the bins to potential contaminants.

Ensuring Chemical Resistance

By many manufacturing standards, the chemicals used in this medical company’s parts cleaning/sterilization process were pretty mild. The parts and basket would be hosed down with a chemical bath containing a fluorescent penetrant, dry powder penetrant, and water at room temperature for 15 minutes.

While these chemicals are minor by some standards, continuous prolonged exposure to water and chemical penetrants can adversely affect plain steel. So, to ensure the trays would be able to withstand near-constant exposure, they were made of a stainless steel alloy.

Whereas plain, untreated steel would quickly form rust after just a few wash cycles, the enhanced resistance of stainless steel keeps the trays from rusting after prolonged exposure to water—maintaining sanitary conditions for the parts held within.

The Results

Through careful consideration of the client’s application and unique needs, Marlin’s team was able to craft a perfect parts-handling solution to ensure streamlined productivity while maintaining sanitary conditions from start to finish.

Even better, Marlin was able to complete the entire basket order from conception to final assembly and shipping in mere days—not weeks or months.

Let Marlin Steel Meet Your Stainless Steel Tray Needs

The medical industry chooses stainless steel because it’s long-lasting, versatile, and able to effectively and efficiently meet the industry’s strict requirements. That’s the same reason you choose Marlin for your stainless steel tray needs. Whether you’re in the medical or pharmaceutical space, or any other that has a need for stainless steel’s qualities, you want to choose a manufacturer that not only has experience in the field, but a qualified and dedicated team backed by that experience.

Marlin understands your industry. Marlin understands steel. If you need a manufacturing partner that can envision how to make your stainless steel tray needs a reality, get in touch with our team today.

.gif)