Carbide cutting tools are well-regarded in a number of industries for withstanding high operating temperatures while retaining their cutting edge—and for having a long useful life overall. However, like with any tool, carbide cutting tools need to be carefully made to create the most useful end product.

Carbide cutting tools are well-regarded in a number of industries for withstanding high operating temperatures while retaining their cutting edge—and for having a long useful life overall. However, like with any tool, carbide cutting tools need to be carefully made to create the most useful end product.

One common step in the creation of the perfect cutting tools is the use of ultrasonic cleaning processes to eliminate any residual dirt or debris from the manufacturing process. Recently, a carbide cutting tool manufacturer reached out to Marlin Steel for a custom ultrasonic parts washing basket design to go with their latest line of cylindrical cutting tools.

Here’s how Marlin Made a better ultrasonic cleaning basket for their cylindrical carbide cutting tools:

Learning the Client’s Ultrasonic Cleaning Process

The first step in designing the best custom cleaning basket for the job is getting an understanding of the equipment the basket will be used with. To this end, Marlin’s production team sent out a custom ultrasonic cleaning basket questionnaire asking for details about:

- The cleaning equipment;

- All chemicals involved in the process;

- The severity of the ultrasonic cavitation process;

- Operating temperatures and durations;

- External dimensions of the parts to be cleaned;

- Details about how the parts needed to be held;

- Whether there was a “no scratch” requirement for the parts; and

- The weight of the parts to be held.

Having all of this information was crucial for making the best possible ultrasonic cleaning basket for the job.

For example, knowing the temperatures involved and whether the cutting tools had a no-scratch requirement would be crucial for determining if the basket would need to be coated. In this case, the carbide cutting tools were unlikely to be marred by contact with bare metal—in fact, they would likely damage a soft polymer coating—so no coating was applied to the basket.

Designing the Ultrasonic Cleaning Basket

One of the major challenges in this particular custom basket design wasn’t protecting the parts during the ultrasonic cavitation process—it was protecting the basket from the sharp cutting edges of the carbide tools. There was a concern that, over time and prolonged exposure to cutting edges being vibrated at ultrasonic frequencies, the wires of the basket could be worn down significantly.

Additionally, the ultrasonic cleaning solution used in the client’s parts cleaning process used an alcohol-based solution to help disinfect the tools being washed. So, the baskets needed to be highly durable and resistant to chemical attack even as potentially-sharp tools abraded their surface.

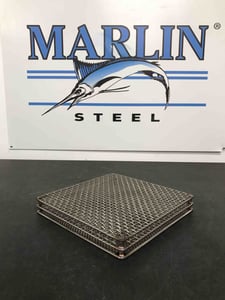

One way to reduce the risk of the cutting tools wearing through the baskets was to minimize the motion of the tools as much as possible. To accomplish this, the basket was given a three-layer design. The bottom layer would be a fine wire mesh for the base of the cutting tools to rest against, with a middle and top layer to keep the tools from moving side to side during the cavitation process.

To further ensure that the wires would last a long time, the wires for the middle and top layers were made from extra-thick steel wires—this would help protect against any incidental cutting or abrasion that may occur during the ultrasonic wash cycle.

Each layer of wire was welded directly to a thick frame supported by a metal pole at each corner of the basket. These poles and the thick wires would help ensure basket stability for the long term.

Once the design was finalized, it was tested using finite element analysis (FEA) software to ensure the stainless steel chosen for the basket could stand up to repeated exposure to the client’s alcohol-based solvent.

Making Heavy-Duty Wire Baskets More Reliably with Robots

After testing, the design was passed to the manufacturing team for assembly. Marlin’s manufacturing team took the design and used it to program a series of wire bending and welding robots that would pull the wires from the spools, bend them into shape, and weld them together with inhuman levels of precision.

The precision of these robots was crucial for ensuring the success of the basket design, as each layer would need to be absolutely consistent to achieve the best results. If any one layer was off by an inch, the cylindrical carbide cutting tools might not fit in the basket, or they might slip right through the bottom—which was kept as open as possible to ensure any runoff from the cleaning process wouldn’t stick to the basket or the parts being cleaned.

Thanks to the speed and exacting nature of automated manufacturing, Marlin’s team was able to rapidly finish the client’s custom wire basket order—shipping out in mere hours what would have taken days or weeks of labor to do by hand. Even better, the precision of factory automation prevented a lot of waste in the form of excess metal or rejected baskets—saving the client time and helping to make the process more eco-friendly.

Have a custom manufacturing challenge that requires a specially-engineered parts washing or handling solution? Reach out to the experts at Marlin Steel to get a custom basket quote ASAP!

.gif)