The absence of test tubes in 18th-century chemistry sets has led historians to believe that they were invented in the early 19th century (earlier texts suggest that tests were carried out in wine glasses!). Of course, once the test tube was invented, there needed to be a way to hold, store, and transport them, leading to the invention of the test tube rack.

Today, wire test tube racks, like those made by Marlin Steel, are the best type of tube racks for the medical and pharmaceutical industry.

QUICK LINKS

- What is a Test Tube Rack?

- Test Tube Rack vs. Test Tube Holder

- Types of Test Tube Racks

- Benefits of Steel Wire Test Tube Racks

- Test Tubes Racks for COVID-19 Testing

- Steel Wire Test Tube Racks from Marlin Steel

What is a Test Tube Rack?

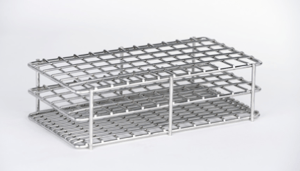

A test tube rack is a piece of laboratory equipment used to hold multiple test tubes upright at the same time. They are especially useful for organizing test tubes when different solutions are being worked on or collected at once. Test tube racks also provide protective storage for test tubes and make transporting and cleaning test tubes much easier.

A laboratory rack for test tubes is also very important in providing safe and efficient environments for physicians, researchers, and scientists to work in without risk of contamination or broken test tubes.

What's the Difference Between a Test Tube Rack and a Test Tube Holder?

While test tube rack and test tube holder are often used interchangeably, they’re very different. A test tube rack, sometimes called a test tube stand, ranges in color, size composition, and material used in manufacture. Test tube racks are made to hold multiple test tubes upright at one time for easy organization, transport, or washing, or for placement in an autoclave or refrigerator.

A test tube holder, on the other hand, is a tool used to hold one test tube. By squeezing the handle, the holder’s spring-loaded jaws open in order to grip the test tube. It’s most often employed when a test tube can’t be touched, such as when it’s being heated over a Bunsen burner or when it contains hazardous or dangerous material. They also put the user at a secure distance when pouring liquids from one test tube holder to another, offering protection from volatile reactions.

Five Types of Test Tube Racks

Test tube racks can be designed to be slanted, stackable, interlocking, or made specifically for drying. They’re also available made from a variety of different materials.

1. Wooden Test Tube Racks

1. Wooden Test Tube Racks

The first classic tube racks were made of wood. While they look neat on a shelf as a vintage item, they’re rarely used as they can become damaged during autoclave sterilization processes and are tough to sanitize, trapping bacteria.

2: Steel Test Tube Racks

2: Steel Test Tube Racks

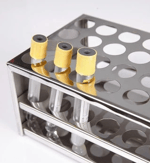

Stainless steel wire racks are highly effective as they are non-corrosive to bodily fluids, sterile, and can hold test tubes during autoclave sterilization processes without becoming damaged.

3: Aluminum Test Tube Racks

3: Aluminum Test Tube Racks

Aluminum may be less expensive than steel wire, however, it is not as strong and is more likely to warp, deform, or bend under weight, force, or heat.

4: Plastic Test Tube Racks

4: Plastic Test Tube Racks

Plastic test tube racks, such as polypropylene test tube racks, Nalgene tube racks, and acrylic test tube racks, were once thought to be the best solution for material handling due to perceived durability but they’re more easily damaged than American steel racks.

5: Foam Test Tube Racks

5: Foam Test Tube Racks

While they’re economical, flexible enough to accommodate many types of test tubes, and able to float in water baths, open-cell foam racks are easily damaged and are unable to be sterilized in an autoclave.

10 Benefits of Steel Wire Test Tube Racks

Here are 10 reasons why steel is ideal as a laboratory rack, holding your classic tubes, centrifuge tubes, microfuge tube, conical tubes, and others.

- Greater Temperature Resistance. With an operating range of -150 F to +1600 F (-101 C to +871 C) and the ability to withstand rapid or cyclic temperature fluctuations, stainless steel test tube racks easily outperform other types of racks.

- Better Corrosion Resistance. Stainless steel resists corrosion in atmospheric and pure water environments and in most acids, alkaline solutions, and chlorine environments.

- Cleaner. Industrial oils, grease, and solvents can stain other types of test tube racks, making them harder to keep clean. Medical-grade stainless steel surfaces are more likely to maintain their original appearance, and with electropolishing, they’re easier to sanitize and sterilize.

- Stronger. Steel has greater tensile strength and is more durable than other types of test tube racks. Ventilation holes designed for washing test tube racks also will not compromise the strength of a wire mesh or laser-cut sheet metal rack like it will plastic racks, for example.

- Greater Versatility. Steel can be coated with plastic to gain the benefits of both products. And, while plastics molding is limited, metal can be molded, shaped, cut, bent, welded, and assembled in a myriad of ways to meet specific needs.

- Greater Heat and Fire Resistance. American-made steel racks can handle autoclave practices that expose them to high temperatures and steam to kill microorganisms. Special high chromium and nickel-alloyed steels also resist scaling and retain strength even at high temperatures. In contrast, other types of test tubes like those made of plastic may melt when exposed to flames, potentially releasing harmful chemicals in the process.

- No Water Absorption: Steel does not absorb water like plastic, wood, or foam test tube racks. Water absorption can also lead to bacterial growth that can be a health hazard or compromise samples or solutions.

- Less Expensive to Manufacture: Marlin Steel uses simple forming methods to make steel products whereas most plastics require a custom mold, requiring a high up-front tooling cost, which often restricts plastic for only very high volume applications.

- Less Expensive Over Time. When total life cycle costs are considered, including initial tooling, stainless steel is often a less expensive material option and its durability makes it a good long-term investment.

- Greater Sustainability. Sure, plastic test tube racks break down faster than steel ones, but most are made from petroleum, a non-renewable, often imported resource. On the other hand, steel is recyclable and reusable with the ability to be melted down and repurposed. Because they can withstand cleaning and sterilization, steel test tube racks can be reused again and again, making them more sustainable and efficient than other means of holding test tubes.

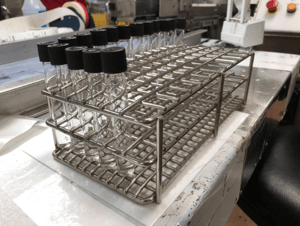

Test Tube Racks for COVID-19 Testing

What are test tube racks used for when it comes to COVID-19? Like most laboratory racks, they’re designed to hold, protect, and transport test samples and even vaccinations. As an American company that cares, Marlin Steel has prioritized contributing to the pandemic response in any way possible. Our high-quality products, including ventilator components and our stainless steel test tube racks, are available for hospitals, labs, and testing kit manufacturers quickly and reliably.

What are test tube racks used for when it comes to COVID-19? Like most laboratory racks, they’re designed to hold, protect, and transport test samples and even vaccinations. As an American company that cares, Marlin Steel has prioritized contributing to the pandemic response in any way possible. Our high-quality products, including ventilator components and our stainless steel test tube racks, are available for hospitals, labs, and testing kit manufacturers quickly and reliably.

As highlighted in the Washington Post and Baltimore Sun, Marlin Steel recently filled a large healthcare provider’s emergency orders for test tube racks that were needed to expedite testing, which helped combat the spread of COVID-19 and save lives. Marlin has also worked with other manufacturers to put together 17 vaccination events (check out the story from the National Association of Manufacturers here).

Steel Wire Test Tube Racks From Marlin Steel

Looking for a quote or have questions about our wire test tube racks? Tell us a little bit about your needs, and one of our experts will contact you shortly to discuss the solutions Marlin Steel can provide!

.gif)