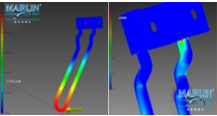

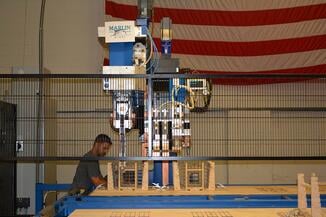

Before we start shaping metal, we run the design through our specialized software to detect faults early. This way, we can:

These simulations use virtual prototypes to determine how your product would hold up during actual use.

FEA software allows us to get a more complex, up close look at the wire basket structure so they can be further evaluated to make improvements. Through this process, Marlin Steel's mechanical engineers are able to enhance your wire forms and understand if they'll meet desired tolerances.

These virtual prototypes help you to:

By testing designs in a virtual simulation before putting wire through the shaping process, you avoid having to create redundant prototype units and waste time with real-world trials of unworkable designs. Fewer wasted prototypes translates into time and money saved, allowing your baskets to be designed, tested and put into production in hours or days instead of having to wait for weeks of design iterations and rejections.

The Occupation Safety & Health Administration (OSHA) has recognized Marlin Steel as a provider of safety insurance for the workplace. On May 18th, 2015 Marlin Steel became the fifth company in Maryland to receive the Safety and Health Achievement Recognition Program (SHARP) award.

Contact us today for all your engineering design service needs.

July 2015 - IDEAL Welder

July 2010 - Punch Press

Fall 2011 - Made in the USA TruLaser

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797