Get a Quote for Custom Wire and Steel Products

Marlin Steel is a leading manufacturer of custom-engineered products from steel wire and sheet metal. Request a quote for your custom products today.

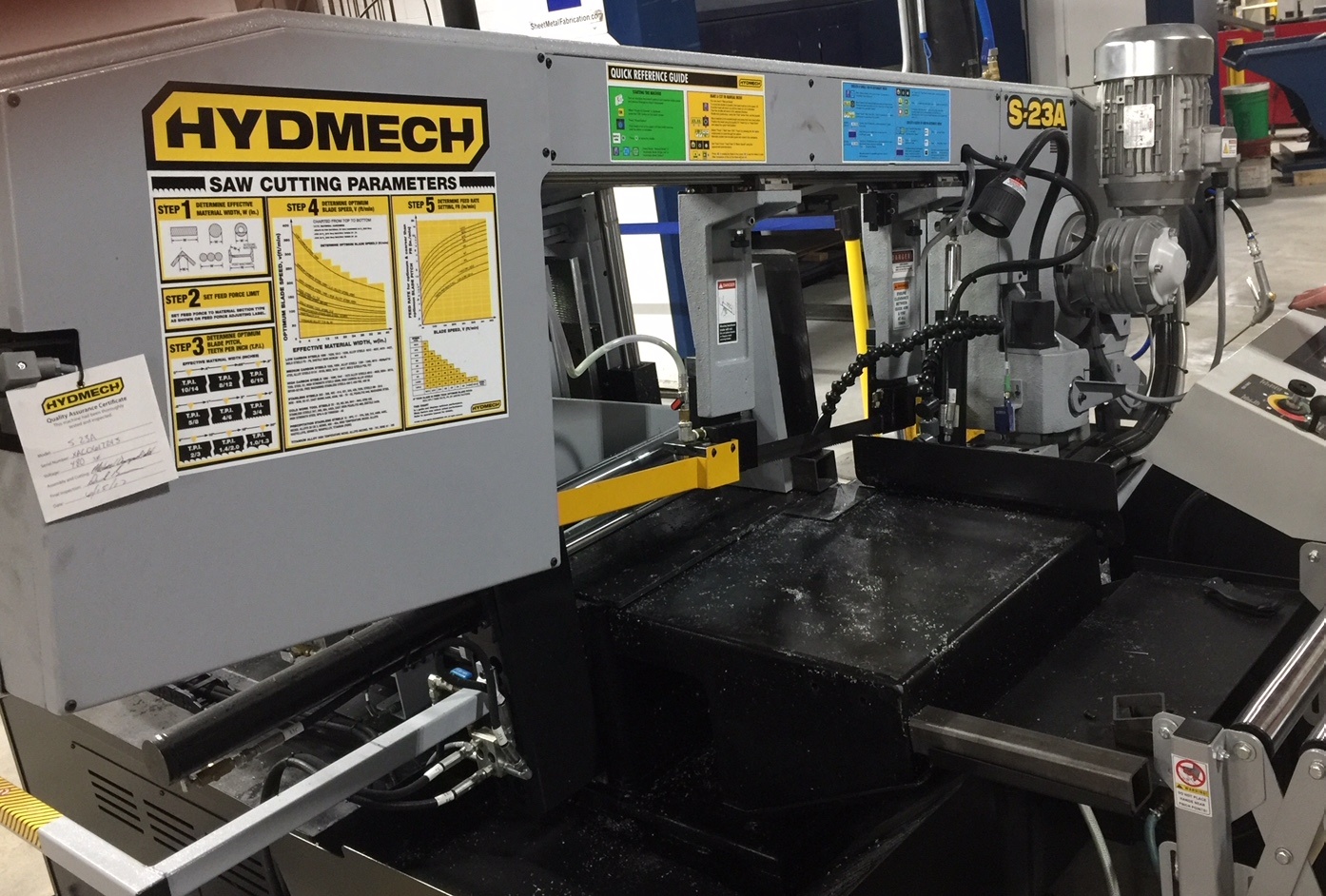

An automatic band saw with exceptional cutting capabilities.

Fixed with a heavy-duty cast iron saw head that can easily swing up to 60 degrees in one direction, the Hydmech S-23A is an automatic band saw that allows for making angular cuts easy and precise as possible. When combined with programmable cutting controls, the easy-swing saw head allows for the ability to make consistently-angled cuts in multiple consecutive parts with a precision unmatched by a manual cutting method.

The Hydemech band saw can create specifically-angled cuts from everything ranging from bars and tubes to wires with the tightest accuracy possible. In fact, the band saw can quickly cut quantity 50 1”x1” tubes with +-0.005” tight tolerances, allowing for the most accurate wire forming manufacturing for products such as hoist baskets and mobile carts. Meeting tights tolerances during custom material handling manufacturing is crucial for ensuring a smooth use of automation and preventing parts rejections.

Besides accurate CNC saw cutting, the addition of the Hydmech S-23A to Marlin’s factory floor operates as efficiently as possible so products are manufactured at quick volumes. For example, the saw’s blade chamber separates materials from the cut part so when a cut is finished, the blade stays in the down position while the shuttle vise retracts the cutting stock. A new length of material is then advanced automatically to repeat and continue the cutting operations. The end result is a more efficient assembly line production and the ability of the Hydemech band saw able to run almost completely unattended without concern about the blade catching on materials and causing parts damage.

With easily-replaced parts and internal regulatory systems, the Hydemech band saw provides an effortless ability to make precise cuts with minimal downtime. Most of the components subject to high-wear - such as the blade brush - are easily replaceable so there is less downtime when replacements are necessary. This allows Marlin’s degreed engineers to spend more time on producing high-quality products ready for delivery rather than waiting for machines to be fixed. Additionally, a flood coolant system regulates the saw blade’s temperature to prevent any heat stress that could further lead to damage and downtime.

For Marlin Steel to uphold its mission to deliver “Quality, Engineered Quick®”, the Marlin engineering team must be equipped with only the most advanced factory automation. A factory floor equipped with the most innovative factory automation tools allows for well-trained employees to collaborate with these automotive tools to deliver the most precise, high-quality products - quickly and efficiently.

One such factory automation tool, the Hydmech S-23A band saw, is used on Marlin Steel’s factory floor to bridge any gaps in production capabilities with its accurate cutting control. With tools like the Hydmech band saw, Marlin can deliver products with the most precise measurements at fast production speeds.

With the Hydmech S-23A saw, Marlin Steel’s engineering team can create specifically angled cuts in wire forms - increasing the capabilities available so that even better custom wire baskets can be formed.

Since the saw increases both the range of Marlin Steel’s manufacturing operations and overall production capacity, client specifications can be met for more custom wire baskets than ever before. Whether you’re looking for a heavy-duty material handling hoist basket or a custom-designed stainless steel wire forms, you can be confident you’re receiving a wide range of metal baskets manufactured with the utmost precision and delivered at speeds unheard of for foreign wire forms.

Marlin Steel is a leading manufacturer of custom-engineered products from steel wire and sheet metal. Request a quote for your custom products today.

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797