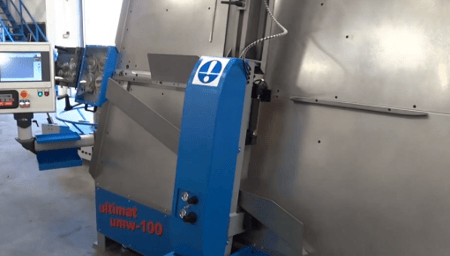

The Ultimat UMW-100

Wire Forming, Strip Forming and Welding Machine

Wire Forming, Strip Forming and Welding Machine

The Ultimat UMW-100 wire forming & welding machine can quickly assemble custom wire forms using CNC wire bending equipment and a medium-frequency direct current (MFDC) welding system.

This system’s MFDC welder, like the IDEAL welder before it, takes incoming 50/60 Hz Mains/Line power, inverts it to 1,000 Hz, and welds at that frequency. Not only does this draw less power than traditional electric welding equipment, it provides a more precisely controlled weld pulse and generates less spatter at the weld site.

Benefits of this system include:

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797