Selecting the Best Metal Basket for Your Aerospace Parts Cleaning Application

Most parts cleaning baskets are made of steel wire mesh, expanded metal, or sheet metal. Each type offers a variety of benefits and limitations depending on the type of aerospace parts they will carry. For example, expanded metal and wire mesh carriers offer plenty of open space that allows air to flow and liquids to drain from the basket. These designs make the drying process faster while keeping chemicals from remaining in the carrier and causing excessive corrosion or staining.

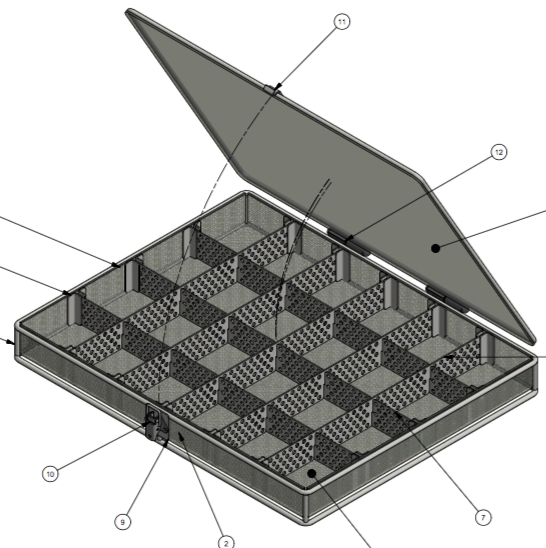

Sheet metal baskets offer an ideal solution for applications with small components, as this type of parts washing basket is constructed without openings to prevent items from falling out. Sheet metal carriers are stronger than expanded metal or wire mesh baskets of the same thickness.

Choosing the best basket material for the critical cleaning of aerospace parts depends on the parts washing process and type of application. Other factors that come into play when deciding on the best type of parts cleaning basket for an application include:

- Cost

- Weight of Basket

- Sharpness of Edges

- Drainage and Airflow

- Suitability for Rough Use

The chemical cleaning of aerospace engine components typically requires specialized equipment such as stainless steel or wire mesh carriers.