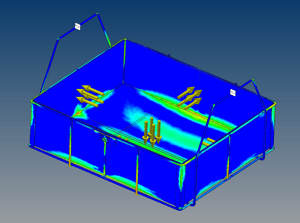

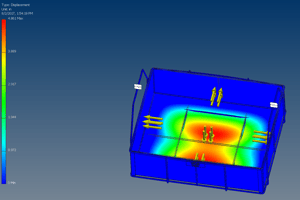

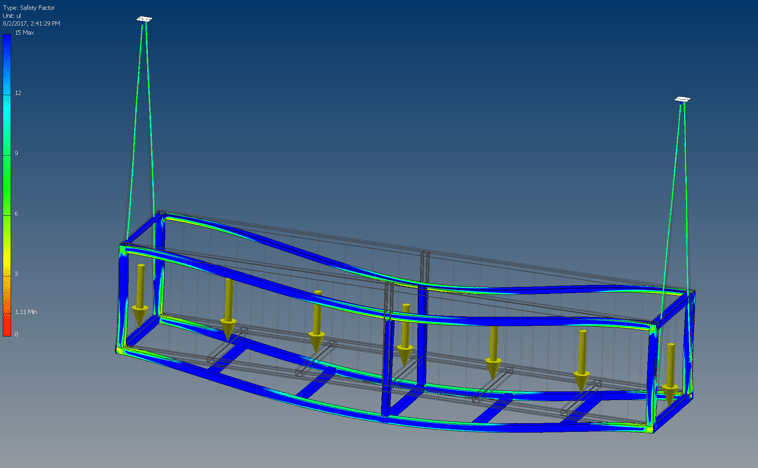

For years, Marlin Steel has used Autodesk physics simulation software to test custom basket designs against the manufacturing conditions the baskets will be used in. Doing this allowed Marlin to make sure that each and every basket design meets all of the client’s performance and durability requirements. It also minimized costs and delays associated with making a series of prototype baskets and retooling for each new prototype.

For years, Marlin Steel has used Autodesk physics simulation software to test custom basket designs against the manufacturing conditions the baskets will be used in. Doing this allowed Marlin to make sure that each and every basket design meets all of the client’s performance and durability requirements. It also minimized costs and delays associated with making a series of prototype baskets and retooling for each new prototype.

This analysis, or Finite Element Analysis (FEA), is a staple of the Marlin Steel manufacturing process.

What is FEA?

As noted on the Autodesk website, FEA is “a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects.”

As noted on the Autodesk website, FEA is “a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects.”

To perform a FEA analysis, the object to be tested is programmed into the computer as a 3D design file. This digital object is then broken down into thousands (or hundreds of thousands) of “finite” elements—such as cube shapes.

The Autodesk software then runs these finite elements through a comprehensive series of mathematical equations to simulate the effects different stresses on each element. The cumulative effects of these different stresses are tallied up on the computer that's running the software and applied to a simulation of the object as a whole.

Basically, the software takes a 3D object design file, breaks it into countless tiny pieces, stress tests each one against different kinds of force, and tracks how those stresses will affect the object as a whole. This allows for an incredibly reliable and accurate simulation of if/how an object would break under stress.

Why Marlin Uses Finite Element Analysis

Every custom wire basket or metal form that Marlin makes is put through a FEA for several reasons:

Every custom wire basket or metal form that Marlin makes is put through a FEA for several reasons:

- To Save Time. FEA on a computer takes mere minutes to program and test, while providing data on the effects of years of use in a specific environment. This eliminates weeks or months of prototype manufacturing and testing, massively improving time-to-delivery for a final product.

- To Cut Tooling Costs. In addition to saving time, FEAs help save money on tooling and production lines for manufacturing prototype “test” baskets. Instead of having to make a prototype for each revision of a design, only one final basket needs to be made.

- To Increase Thoroughness. It may sound counter-intuitive to some, but running a virtual simulation of the stresses that a basket design will be subjected to can actually increase the thoroughness of the test. This is because it is far faster and easier to simulate the cumulative effect of different stresses of years of use in a simulation than it is with a physical prototype. This allows the discovery of flaws that might normally take years of use to become apparent.

In short, FEA helps save time and money, while also being a more thorough way to test a design.

This is why Marlin Steel has made the Autodesk software a core part of the custom steel wire basket design process. Even “stock” baskets are checked using FEA against a customer’s use conditions before they’re made, just to guarantee quality.

It’s all just another part of how Marlin Steel delivers “Quality, Engineered Quick®” to manufacturers the world over.

.gif)