At Marlin Steel, we work to provide industrial clients with precision-manufactured metal forms, but our specialty is in providing clients with what they need to produce the highest quality work in the safest way. In a recent project, a client of ours had just landed one of America’s biggest car manufacturers, which came with significant risk. The OEM had large volume demands requiring investing in new and durable equipment and capabilities. Their requirements included precision tolerances for delivering parts that had to be pristinely washed. There was no margin for error, which our engineering team realized right away.

The client couldn’t afford anything less than the best at that final stage

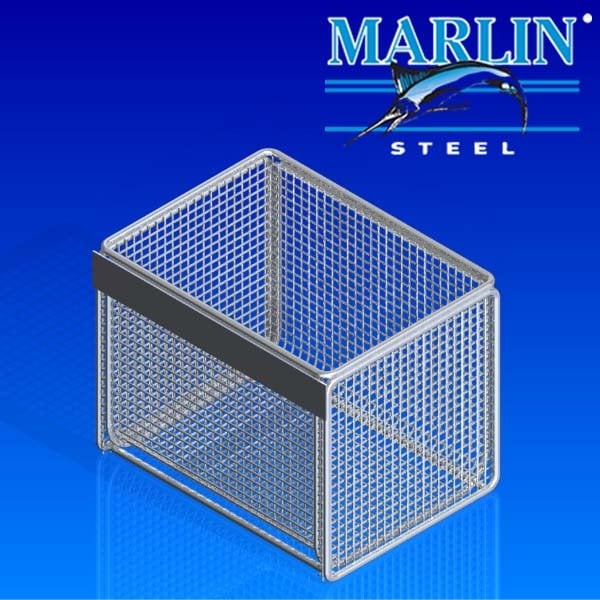

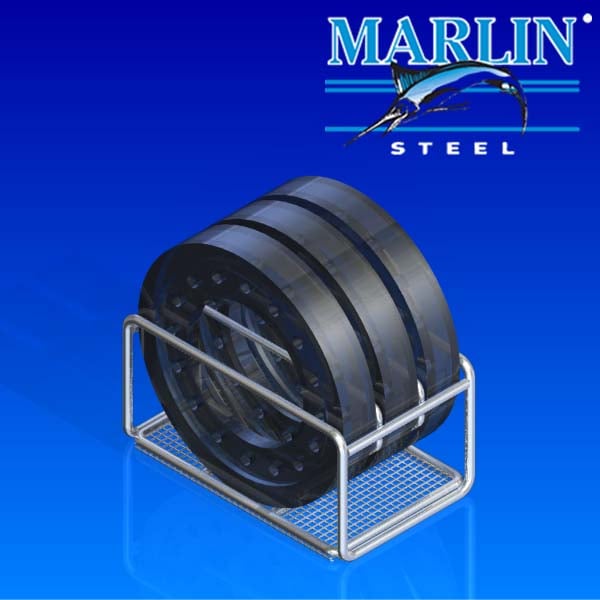

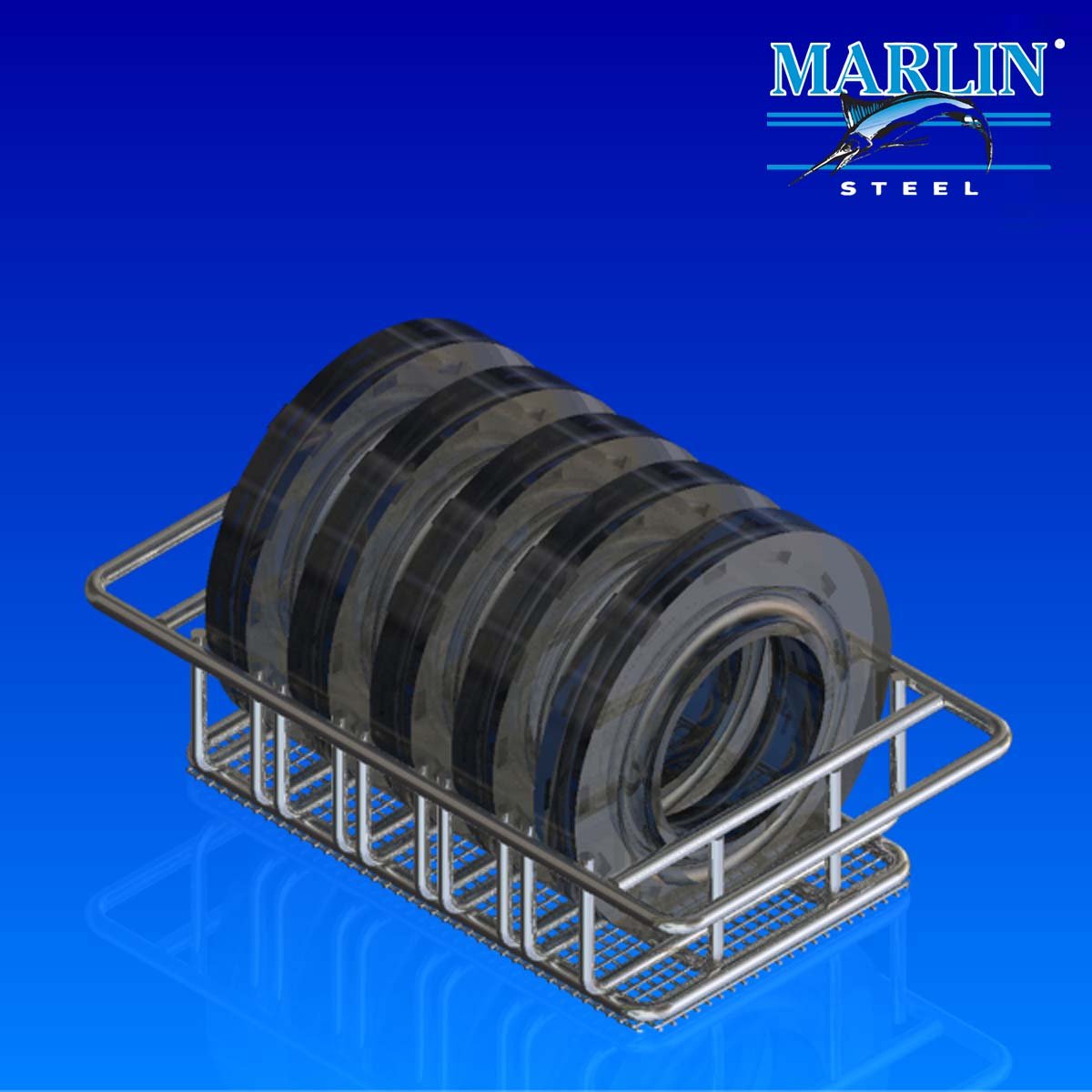

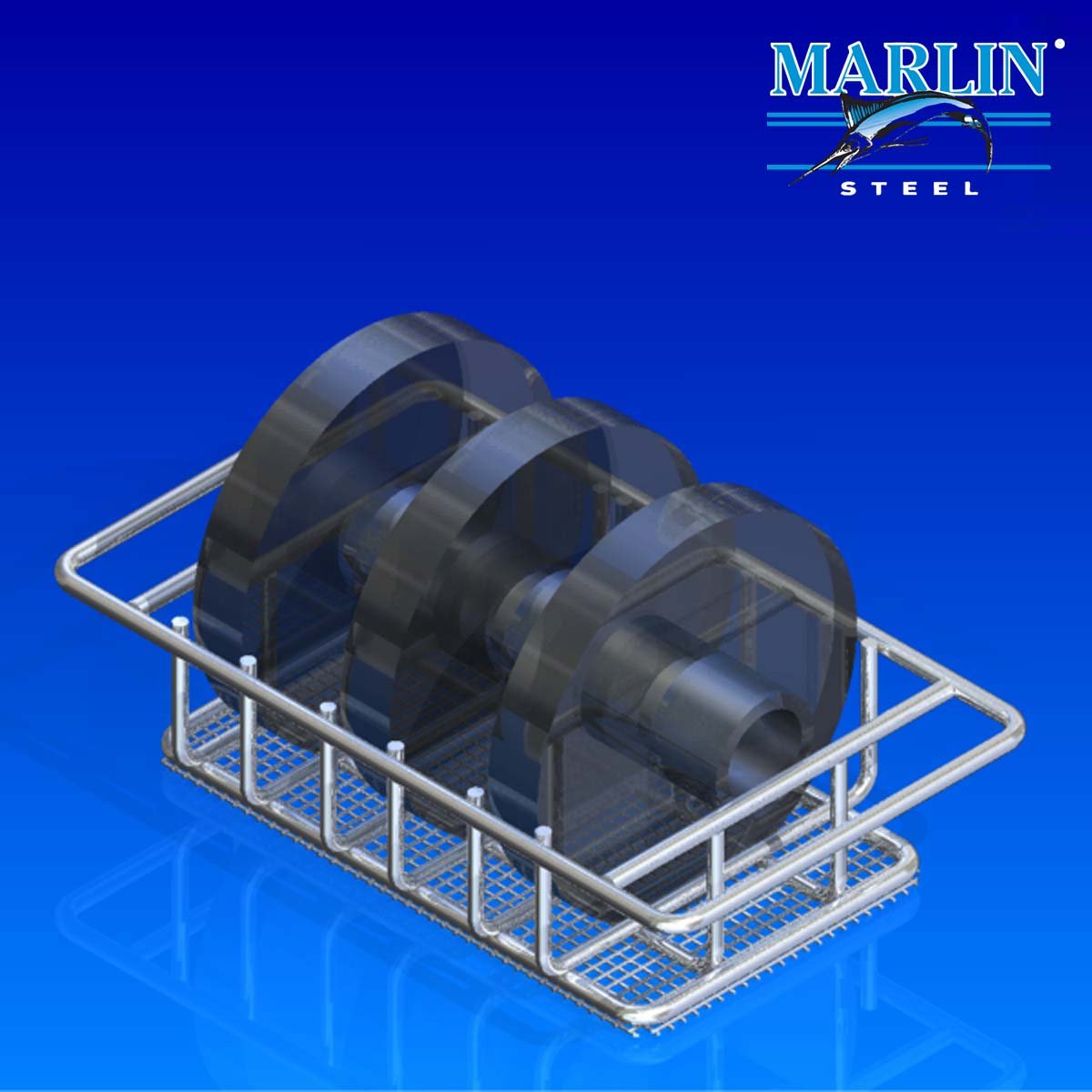

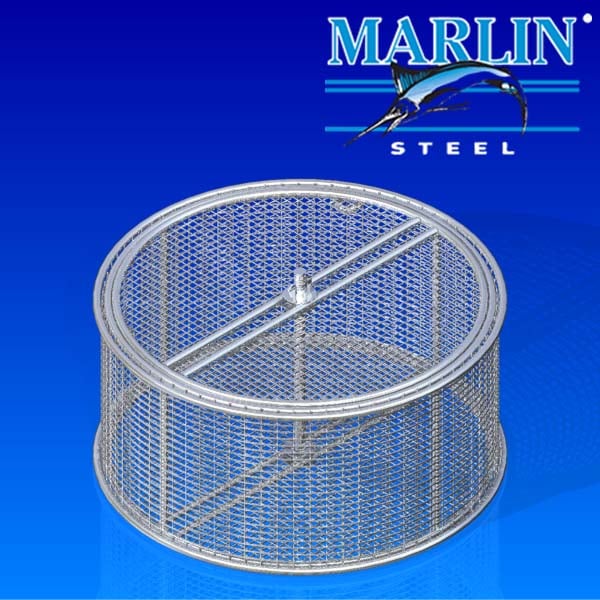

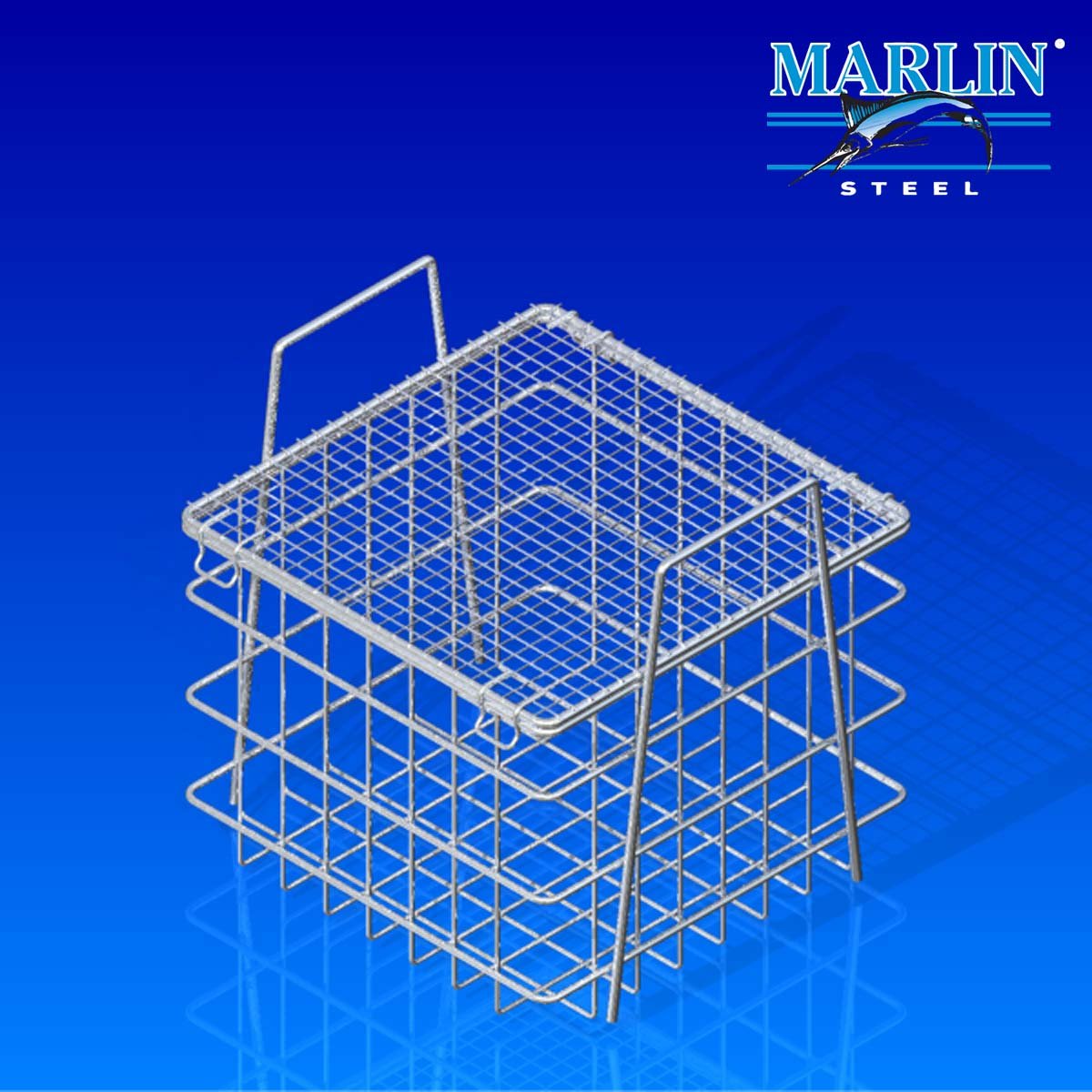

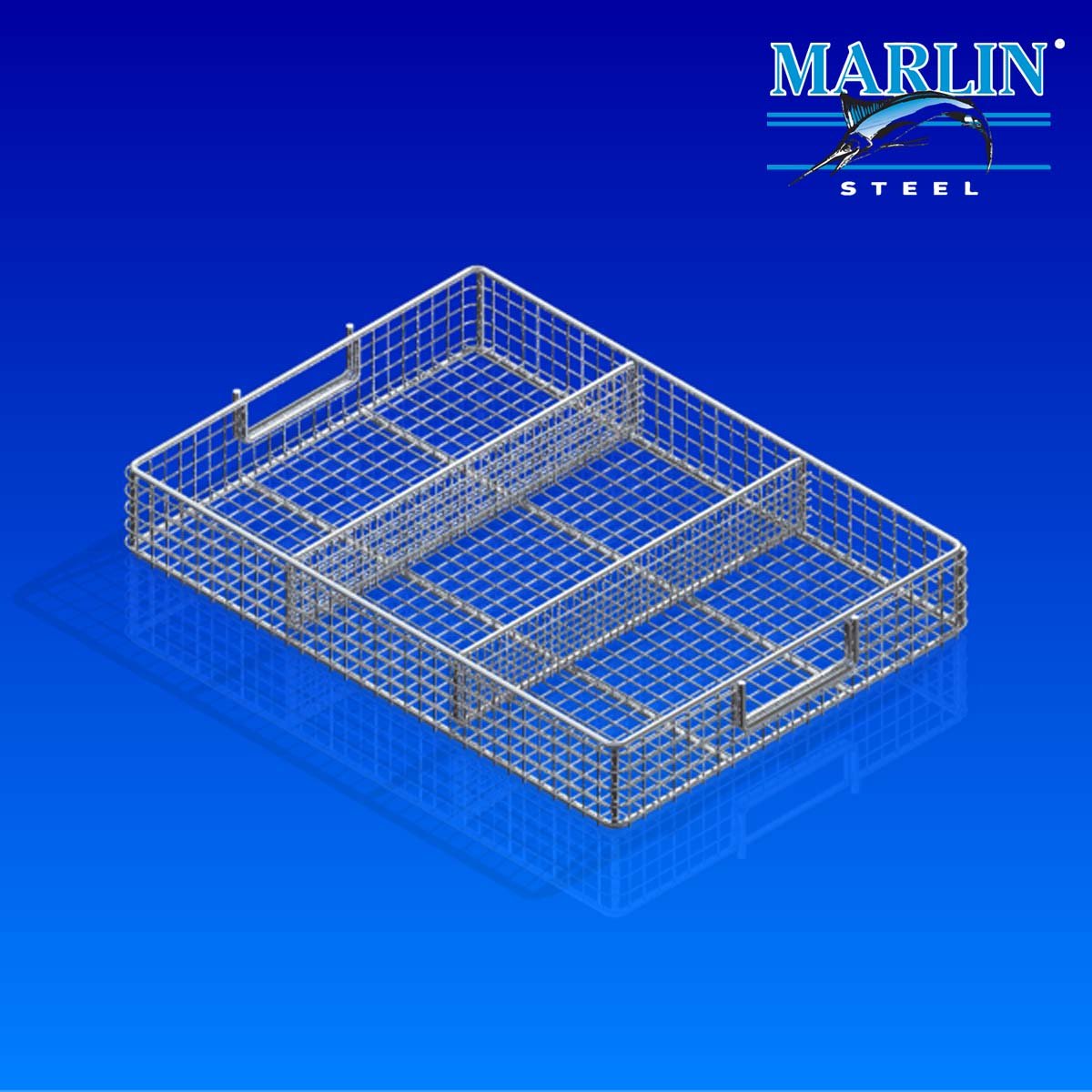

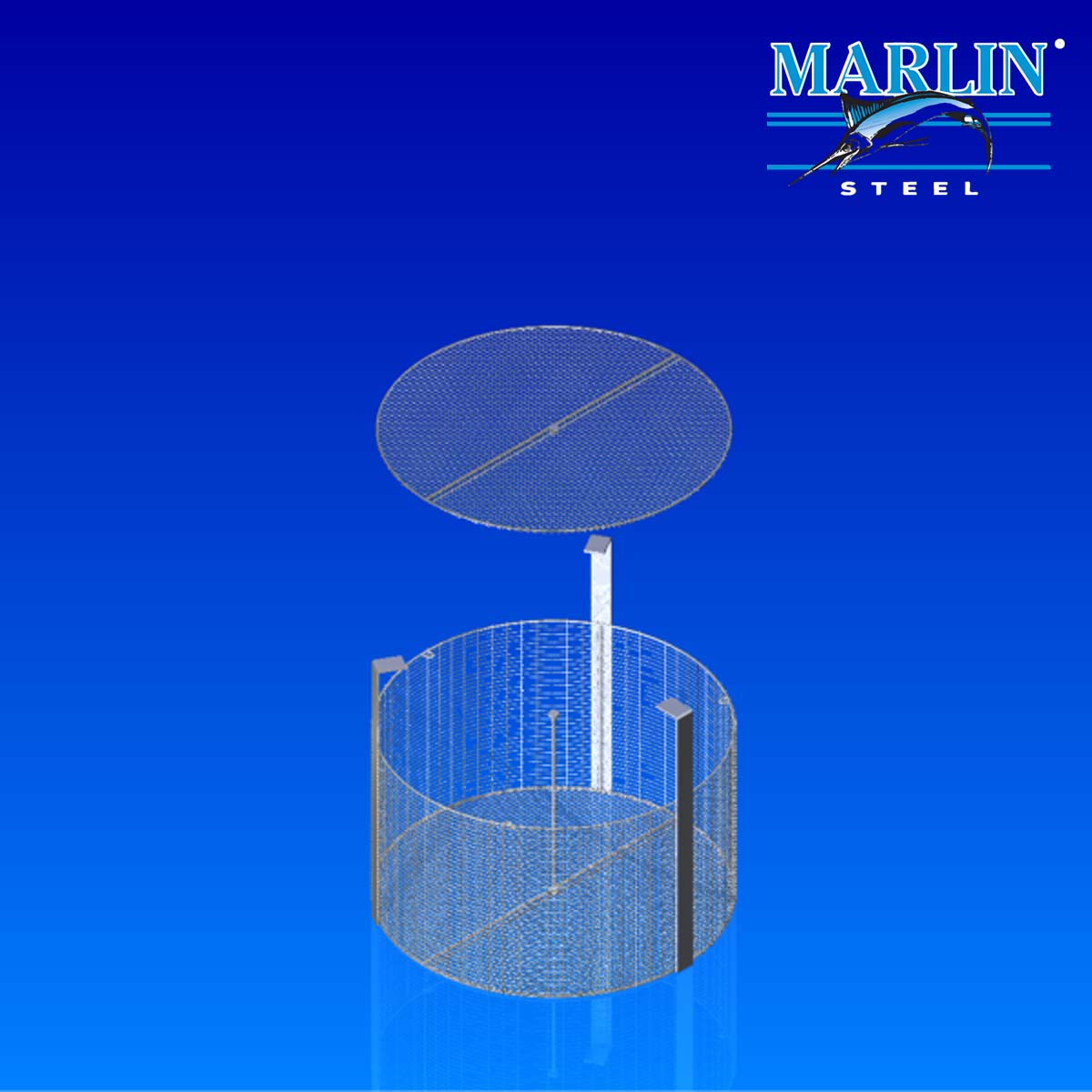

They needed zero scratches during the washing process, zero fluid left in the washed parts, and zero chances for workers to cut their hands on the parts or the containers that we were contracted to make. Their budget was tight, so any efficiencies we could add would be a big win. The client asked us for 150 parts-washing baskets to hold three to five parts each.

For us, that’s the easy part. We can make high-quality custom baskets to client specifications all day long without thinking much about it. However, our engineers bring their brains to each custom project we do. They like to dig around and find ways to improve efficiency and ask, “What’s the real problem here?”

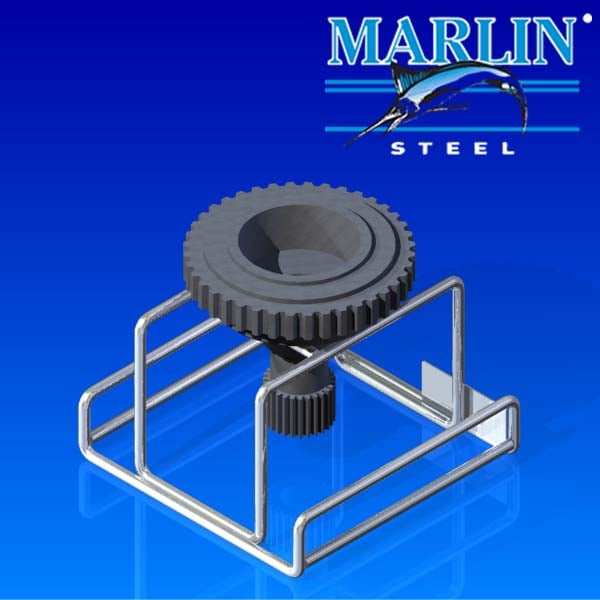

In this case, we saw that the client risked being over-extended. Meeting the OEM’s high production volume requirements meant adding more shifts, more staff, and using more chemicals for parts washing. That’s the problem our engineers focused on. How could we help?

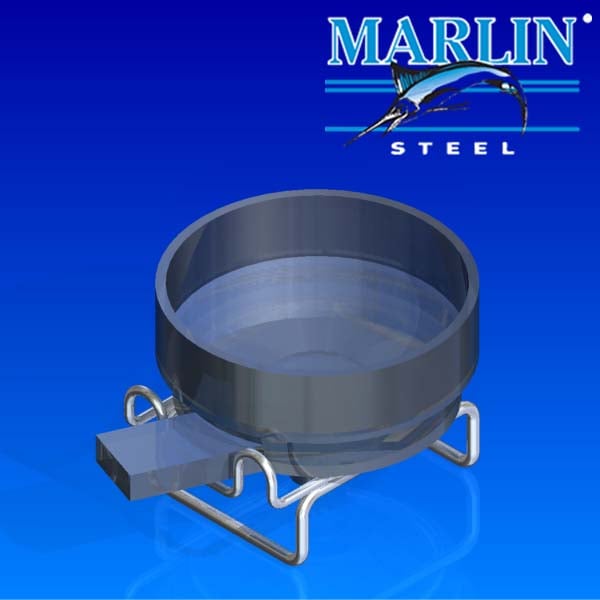

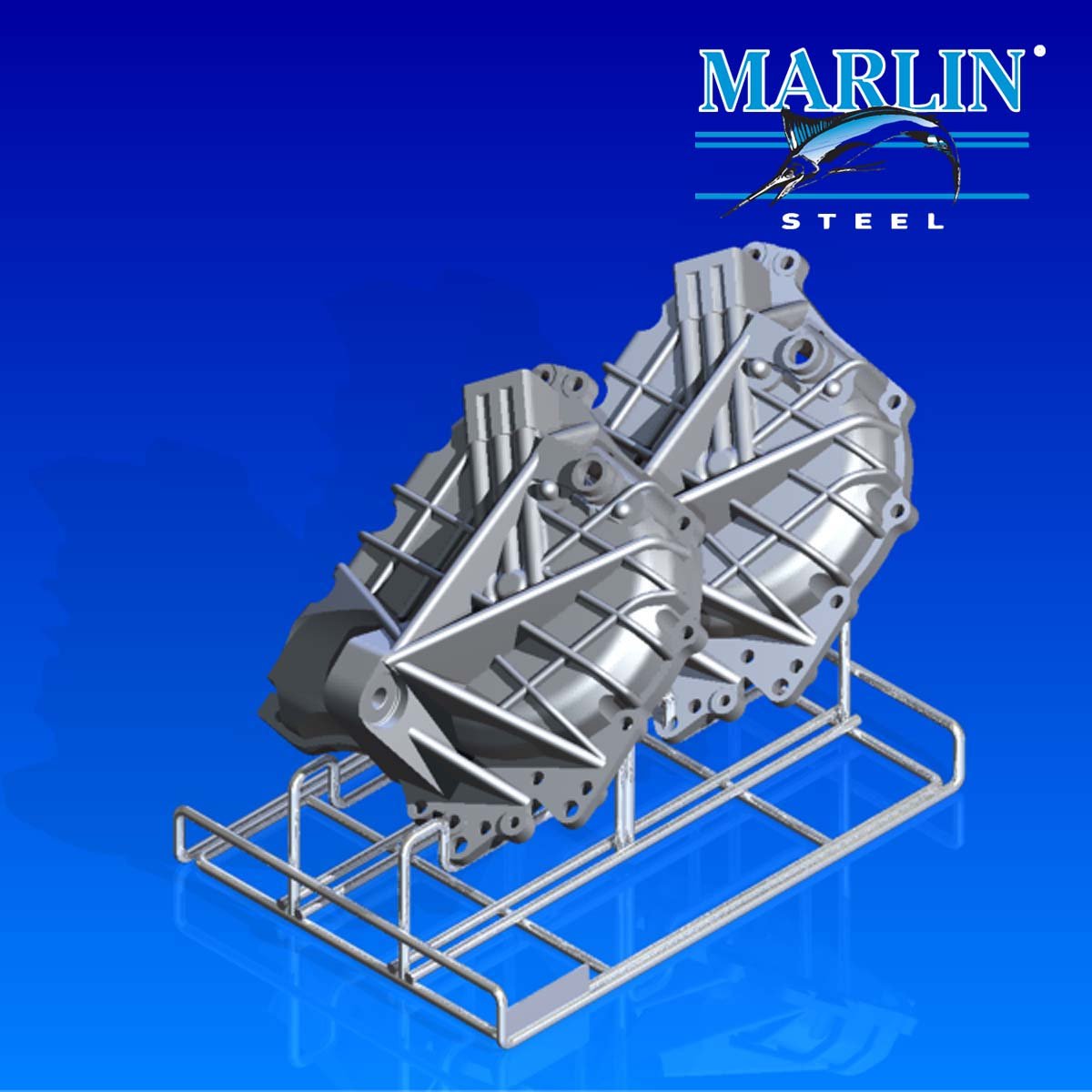

With a detailed questionnaire filled out by the client, our in-house engineering put their industry expertise to work. They brainstormed designs given the constraints on temperature, chemical exposure, part dimensions, washing machine size, and more. They referenced other successful projects, like, “Remember how we designed the fluid exit for that other automotive parts project? Let’s try that.”

Their resulting basket design met all the criteria of the OEM, including the ability to resist corrosion from chemicals and temperature. It was durable and easy to handle, had welded dividers for the parts, and could be held upright to drain fully. It even fit perfectly in the expensive washing machine. All that was a no-brainer for us. The fun part was that we also solved the real problem.

This basket fits eight parts instead of the three or five requested

When the email response came back from the client, saying “This is an excellent improvement!” we could almost see them all jumping up and down and cheering.

Excellent is right! That meant 63% more production volume than they projected, 63% less labor required, 63% fewer washing chemicals to buy and dispose of.

The Marlin Steel team is proud to have ongoing wins like this. We’re able to solve the real problems in part because we are 100% made in the USA, which allows us to move quickly and work closely with our clients. That’s important, but most important is the results from just letting smart, creative folks do what they love. That’s our Engineering Edge.

.gif)