On September 11, Marlin Steel was presented with the 2025 National Metalworking Reshoring Award at FABTECH 2025. The show welcomed more than 65000 attendees, making the recognition even more meaningful on such a prominent industry stage. This award recognizes companies that have successfully brought metalworking operations back to the United States. It is presented by the Reshoring Initiative in partnership with the Precision Metalforming Association (PMA), the Association for Manufacturing Technology (AMT), SME, the Fabricators and Manufacturers Association (FMA), and the National Tooling and Machining Association (NTMA).

Marlin Steel reshored multiple production lines from overseas, spanning industries including medical devices, food processing, and aerospace. Even high-volume commodity items such as pail handles were reshored by applying advanced automation, consistent quality control, and dependable turnaround.

According to the official award citation, Marlin earned the Award by repeatedly demonstrating that automation, engineering, quality, and delivery can enable reshoring even of high-volume commoditized products.

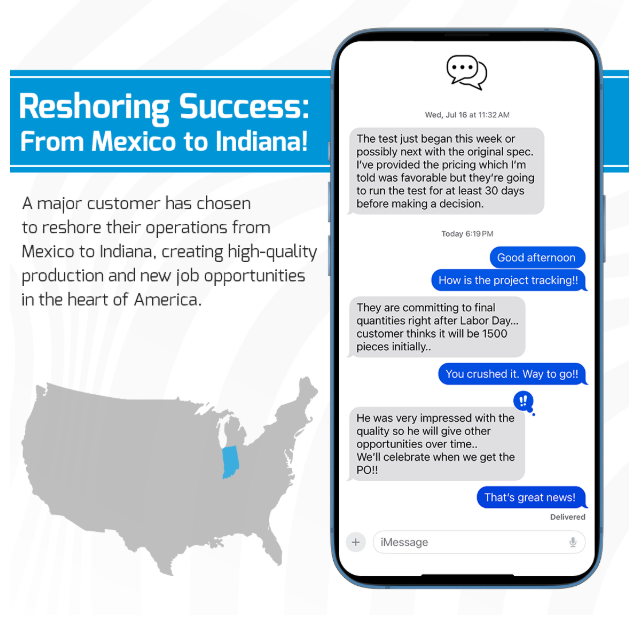

One example involves a reshoring decision by a U.S.-based buyer who previously sourced from Mexico. That buyer moved production of 1500 custom wire racks to Marlin’s operations in Indiana, with final powder coat painting completed in Michigan. These racks had historically been manufactured in Mexico, but were brought back to the United States to improve turnaround time, simplify logistics, and increase product consistency. This successful reshoring project supported American jobs and exemplifies the type of agile manufacturing the award celebrates.

A team of 7 degreed engineers in Maryland, Indiana, and Massachusetts played a pivotal role in driving this effort. Their engineering capabilities, paired with modern fabrication and welding technologies, delivered faster prototyping, tighter process control, and improved responsiveness. Learn more about Marlin Steel’s engineering capabilities.

Key reshoring examples include medical device wash baskets that reduced reject rates from around five percent to under 0.05 percent. Other cases delivered enhanced sanitation and traceability for food processing racks and tighter tolerances for aerospace tooling. These successes demonstrate that even commodity-level components can be reshored when paired with precision and consistency.

Insights from the 2025 Reshoring Initiative Reshoring Survey further underscore why Marlin’s model works. The survey found that key factors enabling reshoring include skilled workforce training, close collaboration between supply chain and customer engineering, and fast delivery. Marlin’s embodiment of all three has been central to its reshoring success and played a direct role in winning the Award.

Marlin Steel expects its reshored revenue to double or even triple in 2026, depending on the volume of upcoming projects, reflecting growing momentum behind reshoring growth fueled by favorable tariff and trade policies.

Marlin accepted the award during an industry ceremony held on September 11 in recognition of leadership in reshoring and domestic manufacturing resilience.

.gif)