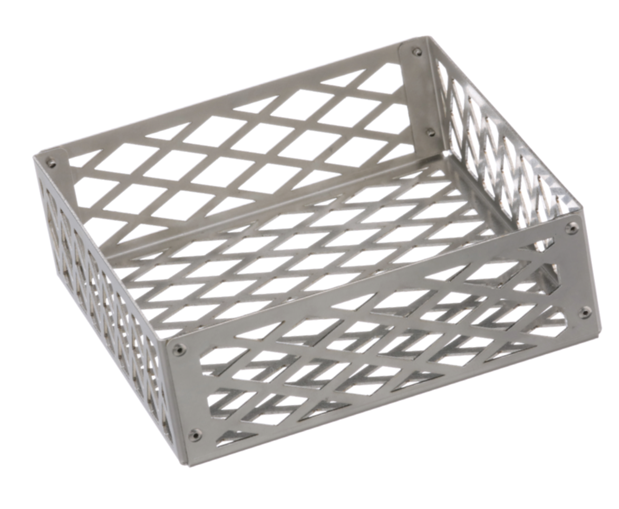

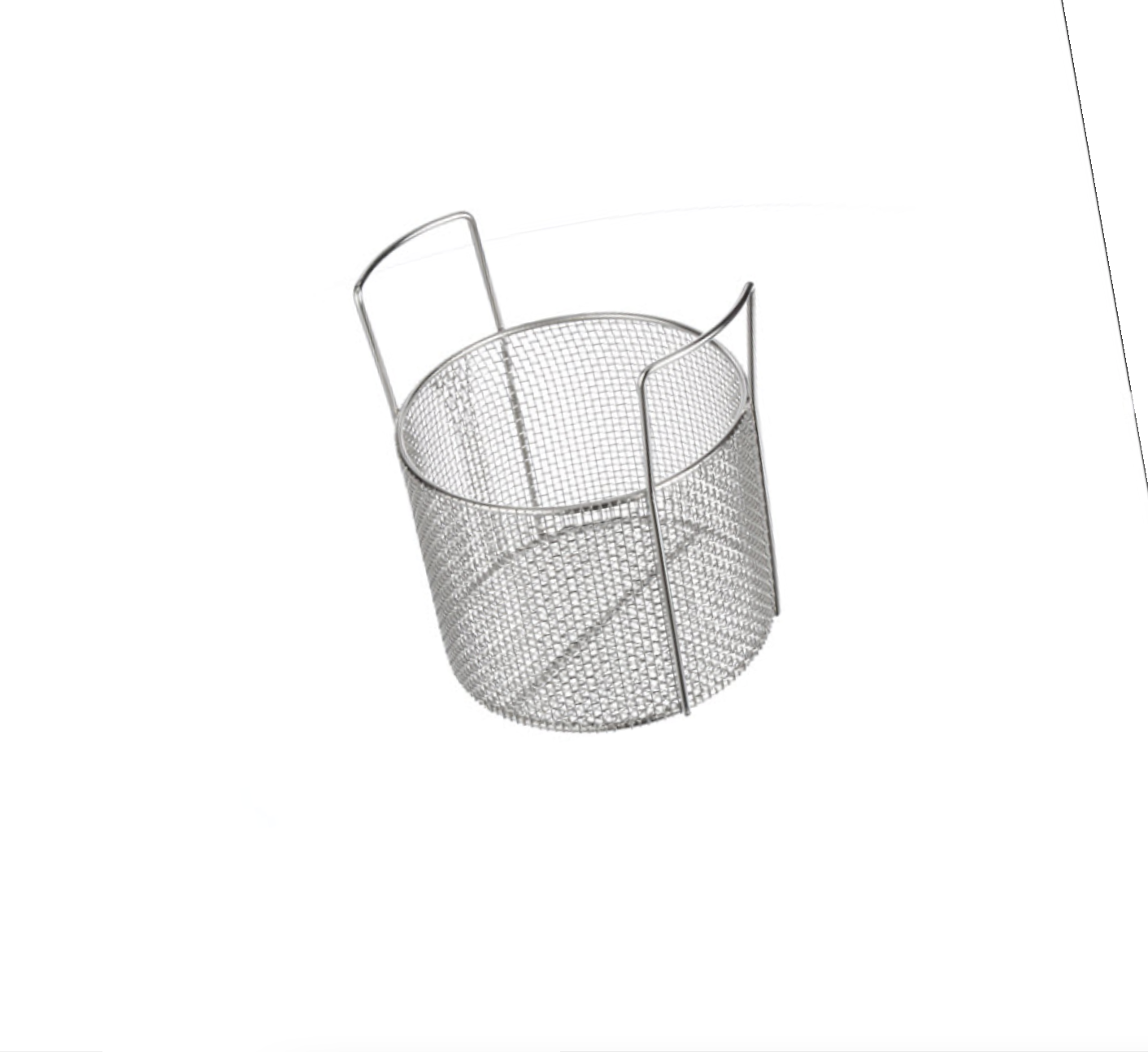

For medical device manufacturers, sterility, repeatable performance, and surface integrity are non-negotiable. The surgical instruments, implant components, and high-precision devices you produce must be transported, cleaned, and sterilized in baskets and trays that won’t compromise hygiene or safety at any point in the workflow.

That’s why leading OEMs rely on electropolished stainless steel medical device baskets—a finishing method proven to improve cleanability, corrosion resistance, and long-term durability.

As a USA-made, ISO 13485–certified manufacturer, Marlin Steel engineers custom medical device baskets and surgical trays that meet the highest standards of sterility and precision—consistently delivered Quality Engineered Quick®.

What Is Electropolishing?

Electropolishing is an electrochemical process that removes a controlled layer of material from stainless steel, dissolving microscopic high points to produce a:

- Brighter

- Smoother

- Cleaner

- More corrosion-resistant

surface. For medical device cleaning and sterilization, no other finishing method matches its performance.

Why Electropolishing Matters for Medical Device Manufacturers

1. Ultra-Smooth Surfaces Improve Sterilization & Reduce Microbial Adhesion

Even high-grade stainless steel contains microscopic pits and crevices that can trap contaminants.

Electropolishing eliminates these irregularities, creating a uniform, mirror-like surface that enhances:

- Sterilization efficiency

- Cleanability in automated wash cycles

- Compliance with validated medical device cleaning protocols

This reduces contamination risk where it matters most—at the point of instrument contact.

2. Superior Performance in Medical Device Cleaning Systems

Medical device baskets face repeated exposure to detergents, disinfectants, ultrasonic cleaning, and high-pressure wash cycles.

Compared to raw or mechanically finished metal, electropolished surfaces provide:

- Faster, residue-free drainage

- Minimal particle retention

- Easier removal of biological material

- Better resistance to harsh chemicals

This ensures your instruments return from cleaning cycles reliably sterile, cycle after cycle.

3. Enhanced Corrosion Resistance for Longer Service Life

During fabrication, tiny inclusions or contaminants can embed into stainless steel. Electropolishing removes these impurities and increases the chromium-rich passive layer at the surface—dramatically improving corrosion resistance.

This is crucial for components exposed to:

- Steam sterilization

- Autoclave pressure

- Repeated thermal cycling

- Chemical disinfectants

The result: longer-lasting baskets and fewer replacements, protecting both your instruments and your bottom line.

4. Eliminates Burrs, Sharp Edges & Particle Shedding

In medical applications, burrs and sharp edges are unacceptable—they can damage instruments, pierce sterile wraps, or trap debris.

Electropolishing naturally:

- Deburrs edges

- Rounds micro-features

- Prevents particle shedding

- Removes hidden crevice points

This ensures smooth, safe handling throughout your sterilization workflow.

5. Supports Precision Fit for High-Value Medical Devices

Precision devices require precision handling. Any surface variation can alter how instruments rest, latch, or seat within a basket.

Electropolishing supports:

- Accurate dimensional consistency

- Stable instrument positioning

- Reliable fit for custom surgical trays and assemblies

OEMs producing implants, scopes, and delicate surgical tools especially benefit from these tight tolerances.

How Marlin Steel Applies Electropolishing for Superior Medical Device Baskets

Marlin integrates electropolishing into a validated, ISO 13485–certified workflow to ensure every basket meets strict medical manufacturing standards. Our electropolished stainless steel baskets deliver:

- Improved sterility

- Reduced contamination risk

- Consistent surface finish and geometry

- Exceptional autoclave durability

- Increased resistance to chemicals and cleaning agents

All designed and manufactured in the USA.

Whether you need baskets for ultrasonic cleaning, sterilization, packaging, transportation, or complex instrument assemblies, Marlin Steel builds custom solutions engineered for medical-grade performance—and delivered Quality Engineered Quick®.

Upgrade to Electropolished Precision—Made in the USA

Electropolishing isn’t just a finishing choice—it’s a critical quality and safety requirement for medical device manufacturers committed to protecting patients and preserving instrument value.

Request a custom electropolished medical device basket today, built to your specifications and manufactured under the highest U.S. quality standards.

.gif)