Stainless steel medical instrument trays can be a crucial part of your medical parts finishing process. The right stainless steel medical tray can help you improve efficiency by reducing damage to delicate medical instruments (minimizing reprocessing/remanufacturing), ensuring more thorough parts cleaning, and aiding sterilization.

Stainless steel medical instrument trays can be a crucial part of your medical parts finishing process. The right stainless steel medical tray can help you improve efficiency by reducing damage to delicate medical instruments (minimizing reprocessing/remanufacturing), ensuring more thorough parts cleaning, and aiding sterilization.

But, how can you choose the best stainless steel tray for your needs?

What to Consider when Choosing Stainless Steel Instrument Trays

1: How Your Medical Instrument Trays Will Be Moved?

How do you plan on moving your medical instrument trays between processes? Will you use a conveyor belt, a robotic hoist, or have a person pick it up and move it?

The way you plan to move your stainless steel surgical trays will play a role in your choice of which instrument tray to use. For example, if you plan to have someone move the tray manually, then selecting a tray that has large handles makes sense. On the other hand, if you plan on using a conveyor system to move trays between processes, then using a stainless steel instrument tray with a bottom designed to prevent snagging on conveyor belts makes more sense.

2: Which Sterilization Tray Stainless Steel Grades You Should Use?

There are hundreds of different formulations of stainless steel, each with unique properties. Two of the most popular types of stainless steel to use for medical manufacturing applications are grade 304 SS and grade 316 SS.

These two stainless steels are very similar (both being austenitic types of stainless steel). However, grade 316 stainless steel has a higher resistance to chlorides, such as salt, which are common in bodily fluids. So, for applications involving blood or other bodily fluid samples, 316 SS is often preferred.

On the other hand, grade 304 stainless has an excellent general resistance to chemical corrosion. This makes 304 SS ideal for a wide variety of manufacturing applications, such as parts washing. In fact, 304 stainless is sometimes called “surgical steel” because it is frequently used for surgical implements (needles, scalpels, etc.).

When choosing a stainless steel medical instrument tray, it’s important to consider the specific chemicals that the trays will be exposed to. Otherwise, the wrong type of stainless steel might be used, compromising the tray’s useful life.

3: How Delicate Are the Medical Components Being Processed?

Do the medical products/components being processed have a strict “no scratch” requirement for processing? Would contact between separate products or components cause damage to them?

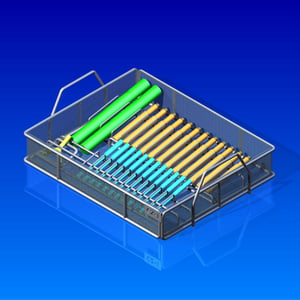

If so, it may be prudent to use a stainless steel surgical tray with a lid and dividers. The dividers can help keep parts from coming into contact during processing, while the lid helps ensure that no parts fall out of the tray during any washing or sterilization processes.

Adding a semi-soft polymer coating can also be useful for protecting parts, but this should be balanced against the need to ensure thorough sterilization, since it is often easier to sterilize bare metal trays than it is to sterilize ones coated with plastic.

Also, when picking lids for stainless steel medical instrument trays, consider whether you want a lid that allows air flow or a cover that completely seals the basket. The former is better for parts washing and drying, while the latter can help to seal the tray against outside contaminants.

Some medical manufacturers get the best of both worlds by using steel wire lids for individual trays and storing them in a cart with a removable cover to move the trays from one process to the next.

4: Do Your Medical Instrument Trays Need to be Electropolished?

Electropolishing is a process that strips the top layer of material from a metal form. This leaves a microscopically-smooth surface that leaves bacteria and other microbiological agents with no shelter on the metal form’s surface. Electropolished stainless steel is incredibly easy to clean and sterilize—making it ideal for many medical manufacturing applications.

However, not every medical manufacturing process demands a tray with a flawless surface structure. Using electropolished stainless steel trays is often best reserved for processes requiring strict sterilization controls. For less sensitive manufacturing applications, a plain finish may suffice.

Marlin’s engineering team has years of experience in crafting custom stainless steel wire forms to fit a wide variety of applications.

.gif)