There are several different surgical instrument sterilization processes to choose from, but none are used as commonly as autoclaves. As an effective and cost-efficient sterilization method, it’s become a staple practice in the medical community.

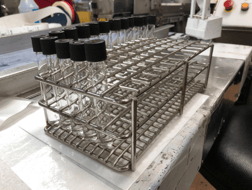

Medical staff can increase the efficiency of the process by investing in medical grade stainless steel autoclave trays, racks, and other relevant equipment.

The Importance of Sterilizing Medical Instruments

Sterilization is primarily about quality control and minimizing risk. Healthcare personnel clean, disinfect, and sterilize instruments to protect patients from infections and minimize risk to staff. Certain sterilization methods also preserve the quality and value of medical instruments, such as stainless steel surgical instruments.

Proper sterilization techniques can:

- Eliminate blood, pus, dirt, and other foreign contaminants.

- Prevent corrosion of expensive tools.

- Decrease the number of germs and non-sterilized bacteria on the surface of the equipment.

- Promote the safe packaging, assembly, and transportation of equipment.

Medical Sterilization Methods Using Autoclaves

Autoclaves are used to sterilize equipment with very high temperatures and steam. Steam sterilization is one of the most effective, safest, and cheapest sterilization methods used on most medical devices. The only times they aren’t considered for use are when a medical device is heat-sensitive or it can’t be steam-sterilized.

The medical instrument is sealed in an autoclave pouch, which is designed to maintain the integrity of the seal while allowing for disinfection, and then placed on an autoclave tray or rack. The autoclave then applies an intense amount of pressure and heat to destroy any microorganisms.

For the autoclave procedure to be effective, specific temperatures must be reached and maintained for a certain amount of time.

| Minimum Temperature | Minimum Amount of Time |

| 121°C (250°F) | 30 minutes |

| 132°C (270°F) | 4 minutes |

Temperatures and time limits can vary based on what’s being sterilized and what method of autoclave sterilization is being performed. The most commonly-used sterilization methods and autoclave tools are:

- Gravity displacement sterilizer

- High-speed pre-vacuum sterilizer

- Steam flush-pressure pulsing process

Gravity Displacement Sterilizer

In a gravity displacement sterilizer, steam is administered at the top of the sides of the sterilization chamber and forces air out of the bottom through a drain vent. This is possible because the steam is lighter than air. Gravity displacement autoclaves are mostly used for laboratory media, water, pharmaceutical products, regulated medical waste, and nonporous equipment that can withstand direct contact with steam.

High-Speed Pre-Vacuum Sterilizer

A high-speed pre-vacuum sterilizer is similar to a gravity displacement sterilizer. However, this sterilization unit is equipped with a vacuum pump to remove air from the sterilization chamber before the steam is administered.

Steam Flush-Pressure Pulsing Process

Air is rapidly removed by repeatedly alternating a steam flush and pressure pulse at a rate above atmospheric pressure.

Why Medical Grade Stainless Steel is Superior for Autoclaves

Medical grade stainless steel surpasses the effectiveness of other materials, such as plastic or wood, by a vast margin. Stainless steel is more durable than plastics and can withstand repeated impacts, scratches, and high thermal temperatures. In each of these areas, stainless steel trays far outperform their plastic equivalents. Its smooth surface and temperature tolerances also make it ideal for sterilization practices.

Stainless steel is also corrosion-resistant, which is imperative in the medical industry, as it will come in contact with body fluids and medical corrosives regularly.

As a sustainable, cost-effective option, medical-grade stainless steel is the superior choice. While upfront costs are higher than other alloy choices, such as aluminum, stainless steel has a longer useful life and won’t need to be replaced as frequently as other options.

Using Custom Autoclave Racks and Autoclave Pouches

Using custom racks, trays, and pouches can allow for more efficient sterilization processes, as all of your autoclave equipment is built specifically for your medical instruments and autoclave machine. Sterilization time and effectiveness will improve, allowing for a more efficient team of medical staff.

How Marlin Steel Can Help

Marlin Steel has been working with companies in the medical industry for years, producing custom stainless steel wire racks, medical trays, and even test tube racks in support of the Coronavirus testing effort. Marlin’s team of experts has mastered manufacturing medical grade stainless steel equipment. Reach out to the team at Marlin Steel today to learn more about how to improve your autoclave sterilization methods with stainless steel wire racks and baskets.

.gif)