In today's manufacturing landscape, precision and reliability are essential, especially when designing and producing custom wire baskets. From aerospace to medical, customers expect not only durability but also engineering excellence. Among wire basket manufacturers in the USA, Marlin Steel stands out for its consistent focus on innovation, speed, and quality.c

Engineering-Driven Design from Start to Finish

At Marlin Steel, every project begins and ends with engineering. More than 20% of our workforce holds mechanical engineering degrees, allowing the team to approach each custom wire basket project with a high level of technical expertise.

We have seven degreed engineers located across Maryland, Indiana, and Massachusetts, giving us a flexible, regional presence to support customers across the U.S. This geographic footprint also enhances collaboration across our facilities, ensuring smart design decisions are carried from blueprint to finished product.

Our engineers use advanced CAD modeling software to design wire baskets that meet specific performance requirements. Each design is evaluated using stress analysis and Finite Element Analysis (FEA), helping to predict how baskets will hold up under real-world conditions. This process ensures that your baskets are not just functional but also reliable for long-term use in demanding environments.

Precision Automation and Custom Tooling

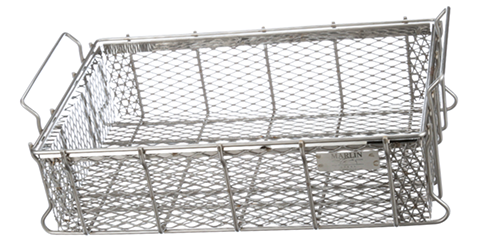

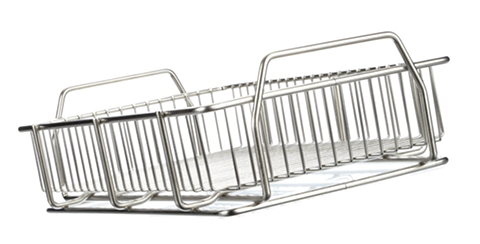

Marlin Steel’s manufacturing facility features a full range of advanced automation technologies. The equipment includes CNC wire benders, laser cutters, and robotic welders. These tools enable us to manufacture wire baskets with complex geometries while maintaining tight tolerances and consistent quality.

Our in-house custom tooling capabilities further support production consistency. By controlling every step of the process, Marlin Steel ensures that each basket meets exact customer specifications, whether for a small prototype run or a large production order.

Proven Results Across Critical Industries

Marlin Steel’s engineering capabilities are trusted across a variety of critical industries. Aerospace, medical, automotive, and food processing companies depend on our custom wire baskets for applications that require both precision and durability.

Our patented designs, ISO 9001:2015 certification, Medical Device ISO 13485:2016 certification, and fast prototyping services help our customers receive reliable products within shorter timelines. Whether you require sterilization trays for healthcare settings or baskets for jet engine components, Marlin Steel’s engineering expertise helps ensure reliable performance and precise results in critical applications.

Marlin Steel: True Industry Leaders Backed by Engineering Excellence

Among wire basket manufacturers, Marlin Steel has earned its reputation through expert engineering, advanced automation, and a focus on customer-driven design. Our approach is not just about making baskets; it’s about solving complex engineering problems with precision, consistency, and speed.

To learn more about Marlin Steel’s engineering capabilities or to request a quote for custom wire baskets, contact the team today.

.gif)