Get a Quote for Custom Wire and Steel Products

Marlin Steel is a leading manufacturer of custom-engineered products from steel wire and sheet metal. Request a quote for your custom products today.

One of the most successful and reliable bending press brake machines in the world.

Marlin Steel has never skimped on providing only the highest quality manufacturing available. Our custom wire baskets and products are engineered with the tightest parts tolerances and impeccable craftsmanship, powered by a heavy investment in the highest quality factory automation on the market.

Factory automation serves the dual purpose of creating a safer factory environment for employees, as well as improving the consistency of metal baskets and wire forms at rates impossible for human labor to match. One of these innovative machines responsible for the unmatched precision of Marlin’s products is the Trumpf 5230 press brake.

By using the Trumpf press brake, Marlin’s engineering team can produce automatic sheet metal bending for both thick and thin materials reliably and quickly so you can receive your custom wire baskets as soon as possible.

Factory automation allows Marlin Steel to create the most precise bends possible for sheet metal and wire forms. When tight parts tolerances matter, it’s important for degreed engineers to be as exact as possible. Factory automation, such as in the form of the Trumpf press brake, allows Marlin Steel to perform perfectly uniform and intricate bends unable to be matched by human labor alone.

The Trumpf press brake is one reason why Marlin Steel can produce such high-quality stainless steel wire baskets and metal forms within such a short amount of time. So, you can thank factory automation for allowing you to receive the most precise wire forms within just days of your order.

Find out how Marlin’s factory automation and fast domestic delivery can get you a custom metal form with Quality Engineered Quick®.

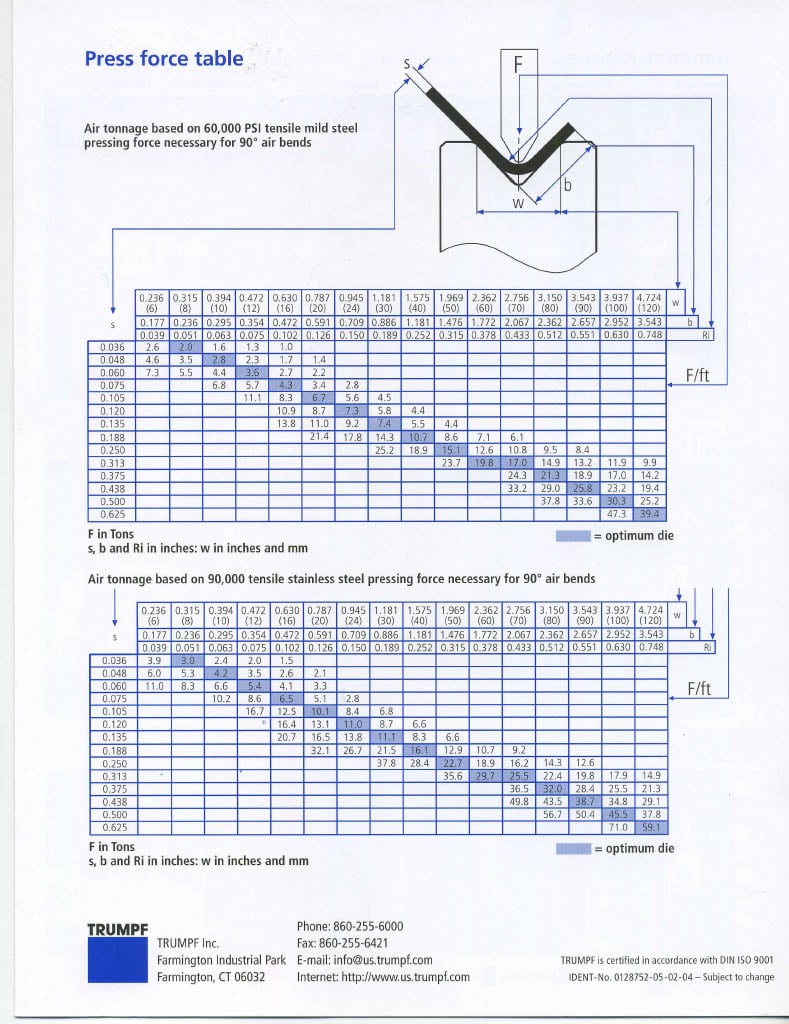

This is a variable question. See attached tonnage chart with tensile of 60,000 PSI for Steel. If your material varies you can adjust accordingly. The other variable is the die opening. The larger the die opening, the thicker you can go. The blue highlights are the optimal die usage for each material. You are at 253 US Tons so 25.3 tons per foot which means at 10 feet you can bend about .438” in a 100mm wide die.

Z axis is left to right so I assume you may be talking about the X-Axis which is front to back. This tolerance is .0015” from a gauging position. However if you are making long bends your material can have a camber in the middle so you can add support in the middle to help if needed.

Marlin’s manufacturing team uses the Trumpf press brake to provide superior productivity and precision. Due to numerous innovations, the Trumpf 5230 is the latest press brake machine tool to provide automated and ergonomic solutions.

As a large press brake capable of bending parts that are over 127’’ in length, the Trumpf 5230 can easily bend parts at angles too complex for other machines. Due to its six-axis back gauges, it can also bend thick sheet metal due to its 230-ton application power - the equivalent of multiple cars!

While the lower tools displacement allows for applications such as folding, the Trumpf 5230 press brake can precisely bend both complex thin and thick parts at high angular accuracy.

With intelligent software and sophisticated factory automation tools. even long profiles can be bent in a straight line as precisely as possible. This combination allows the Trumpf press brake to deliver the most precise bends for all your sheet metal requirements possible.

Marlin Steel’s factory automation is designed to complement human operators, not replace them. The Trumpf press brake is incredibly user friendly with added features for the comfort and safety of its operators, including touchscreens, automatic tool changers, and LED light illumination.

The Trumpf press brake not only operates with minimal noise, but does so at a fast pace of 8.5 in/s, so wire forms can be bent quickly and without discomfort to the operator.

Marlin Steel is a leading manufacturer of custom-engineered products from steel wire and sheet metal. Request a quote for your custom products today.

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797