In medical and pharmaceutical environments, reliability isn’t optional; it's required. From sterilization trays to washing baskets and transport carts, every component that touches surgical instruments must meet the highest standards for cleanliness, durability, and long-term performance. That’s why 316L stainless steel has become the gold standard for manufacturing medical device baskets, especially for facilities focused on consistent sterility and efficient medical device cleaning.

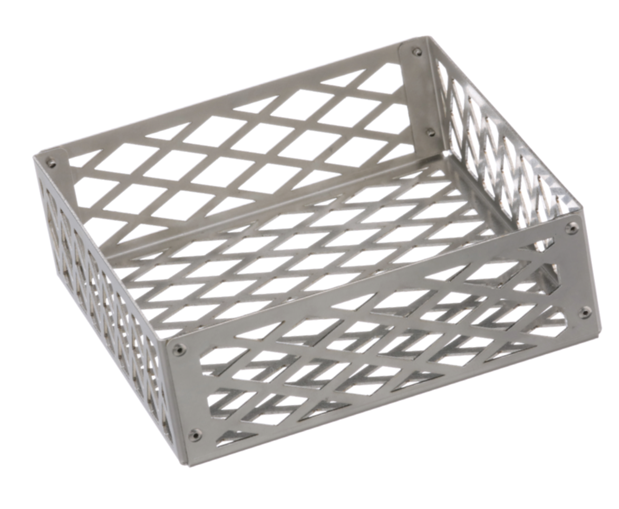

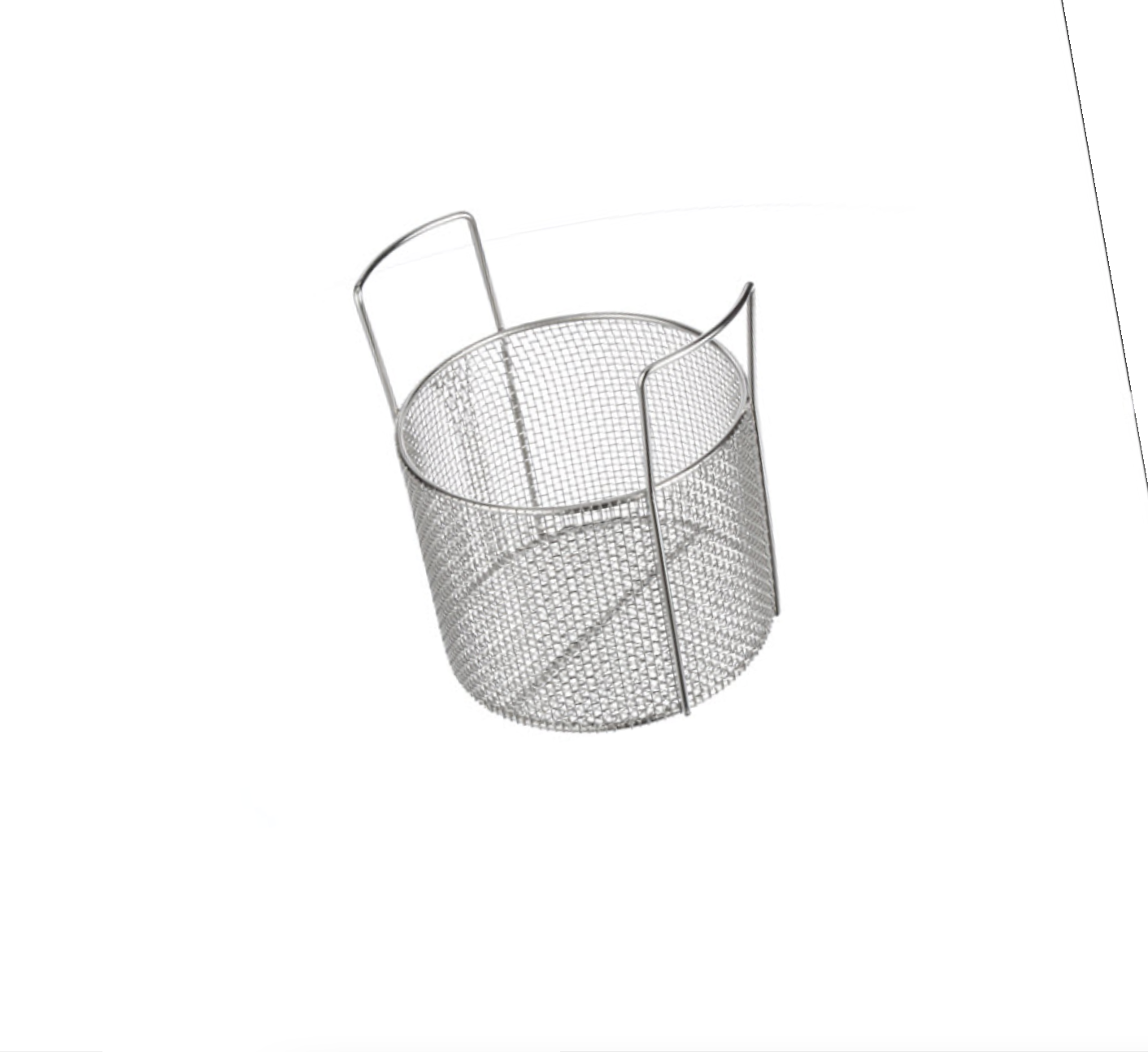

At Marlin Steel, our medical-grade custom wire baskets, ultrasonic cleaning baskets, and sterilization racks are built from premium 316L stainless steel and manufactured under our Medical Device ISO 13485 certified quality system, ensuring every product is Quality Engineered Quick®.

What Makes 316L Stainless Steel Superior for Medical Device Baskets?

1. Unmatched Corrosion Resistance

Medical device baskets, sterilization racks, and ultrasonic cleaning baskets undergo constant exposure to moisture, aggressive detergents, and repeated autoclave cycles.

316L stainless steel contains molybdenum, dramatically improving corrosion resistance, especially against chlorides and the chemicals used throughout medical device cleaning.

This ensures baskets maintain structural integrity and resist contaminant buildup over time.

2. Biocompatibility for Patient-Safe Use

316L stainless steel, and its close counterpart, 316 stainless steel, are industry standards for medical implants, surgical tools, and sterilization equipment because of their exceptional biocompatibility.

For baskets holding instruments before patient contact, this high level of material safety is non-negotiable.

3. Superior Weldability and Precision Fabrication

The reduced carbon content of 316L makes it ideal for precision welding, critical for producing durable, smooth-edge, high-performance medical device baskets, washing baskets, and ultrasonic cleaning baskets.

Marlin Steel’s engineers leverage these material advantages to create:

- High-strength welds

- Smooth, burr-free surfaces

- Complex custom geometries for specialized instruments

These qualities reduce particle shedding and ensure every basket can be thoroughly and consistently cleaned.

4. Exceptional Autoclave & Sterilization Performance

Sterilization equipment demands materials that can withstand:

- High temperatures

- Steam exposure

- Repetitive autoclave cycles

316L stainless steel offers long-term stability under these conditions, ensuring baskets, racks, and trays do not warp, corrode, or degrade, protecting both surgical instruments and critical workflow reliability.

Why Material Matters for Medical Device Cleaning

Efficient medical device cleaning requires baskets designed for maximum fluid exposure, drainage, and cleanability.

316L stainless steel supports this through:

- Fast, consistent drainage

- Minimal contamination risk

- Surfaces resistant to chemical attack

- Easy-to-clean structures with no crevices

When combined with Marlin’s precision electropolishing options, these baskets achieve an ultra-smooth surface finish, reducing microbial adhesion, improving washing performance, and streamlining sterilization cycles.

Marlin Steel: Quality You Can Trust in Medical Manufacturing

As a Medical Device ISO 13485–certified manufacturer, Marlin Steel ensures every medical device basket, ultrasonic cleaning basket, sterilization rack, and transport cart is consistent, traceable, and optimized for validated cleaning and sterilization processes.

Clients choose Marlin because our products are:

- Custom-engineered for surgical tools, implant trays, and pharmaceutical equipment

- Manufactured in the USA using advanced automation

- Delivered Quality Engineered Quick®

- Designed for unmatched performance in demanding medical environments

Need Custom 316L Stainless Steel Medical Device Baskets?

Whether you need a standard sterilization tray or a fully customized basket, rack, or ultrasonic cleaning solution, our engineers deliver precision-built products to support your medical cleaning, sterilization, and operational needs.

Contact Marlin Steel today to discuss your next medical-grade basket solution.

.gif)