Recently, we talked about the utility of baskets with lids, and even discussed how compartmentalized lids could help streamline the parts washing process a little. However, there’s more to making sure that you can wash numerous parts at the same time without damaging them than just making sure that they don’t fall out of the basket.

Recently, we talked about the utility of baskets with lids, and even discussed how compartmentalized lids could help streamline the parts washing process a little. However, there’s more to making sure that you can wash numerous parts at the same time without damaging them than just making sure that they don’t fall out of the basket.

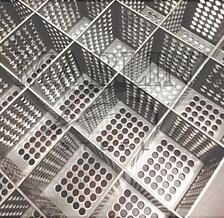

Left to sit loose in a basket, parts that are not properly constrained will bounce and roll around, hitting each other and potentially causing damage. To prevent this, it is important to segment washing baskets so that parts are held apart from one another.

Using Dividers to Wash Multiple Parts

By creating custom-formed dividers for washing baskets, you can compartmentalize the entire basket to make washing multiple different parts much simpler. If you have numerous different small parts that can go through the same washing process, using a basket with dividers can allow you to wash them all at once to save time.

By custom-shaping the dividers, you can make sure that the parts they hold will fit snugly, preventing excessive rattling from the washing process and keeping them from being scratched or damaged. Combining compartmentalized lids with basket dividers allows you to quickly remove one set of parts from the basket if necessary for your process while keeping other parts constrained.

Using Removable Dividers to Increase Utility

While for some parts washing processes, you may want to keep the dividers in the basket indefinitely by welding them in place, you don’t always have to do so. You can maximize the utility of each basket by using removable dividers instead of permanently-attached ones.

With a removable divider, you can put the dividers in for use with multiple smaller parts to keep them separated during their washing process, and then take the divider out for washing larger parts that can still fit in the basket. Naturally, it is best if the basket is designed to hold both sets of parts from the beginning.

Removable vs. Welded

Whether or not you want to use removable basket dividers over ones that are welded in will depend on what you need most from your material washing and handling baskets.

Removable basket dividers provide:

- Greater utility in the number of part types that can be held within.

- Added redundancy by giving each basket more than one use (if the dividers are lost or damaged, the basket can still be used for larger parts until you can replace said dividers).

Welded basket dividers have advantages such as:

- Generally being sturdier.

- Lower likelihood of losing basket parts.

- Eliminate the possibility of using the wrong dividers with the wrong baskets.

If you have multiple different parts baskets that use dividers, sometimes simply making the dividers a permanent part of the basket is the easiest solution for making sure that there is no confusion as to which basket is for which part. However, using baskets with removable and adjustable dividers allows you to wash multiple different kinds of parts with the same basket, which means not having to keep quite as many baskets on hand at once and making storage of the baskets easier when they’re not being used.

Whether you need baskets with removable dividers, welded-in dividers, or no dividers at all, you can be sure that your custom material handling basket is the right one for the job when it is made by an experienced and knowledgeable engineer who designs it to meet your needs.

.gif)