Parts Washer Baskets

Optimize Cleaning Efficiency & Protect Your Parts With Custom Washing Baskets

A clear and bold heading

A more subdued subheading

Optimize Cleaning Efficiency & Protect Your Parts With Custom Washing Baskets

A more subdued subheading

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

OTIF, Reshoring, and Why It Matters to Marlin Steel Customers In today’s manufacturing environment, reliability matters just as much as price. Supply ...

Read More

Modern manufacturing requires more than precise cutting. It requires traceability, accountability, and consistency across every part produced. As ...

Read More

For medical device manufacturers, sterility, repeatable performance, and surface integrity are non-negotiable. The surgical instruments, implant ...

Read More

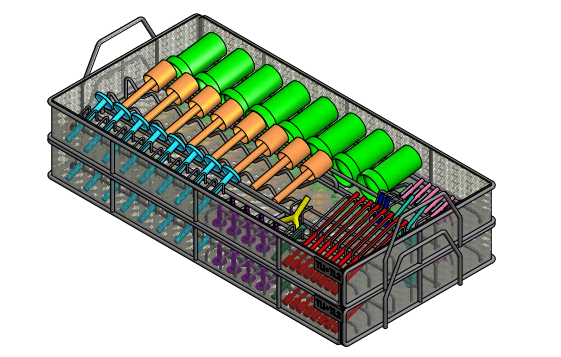

Custom wire cleaning baskets are effective for washing, drying, sterilizing, degreasing, and dyeing parts and products. They can also help your operations combat E. coli, salmonella, and listeria when washing food-handling equipment or produce. Hand washing these baskets, however, is neither time- nor cost-effective and can actually lead to further contamination.

At Marlin Steel Wire Products LLC, we'll outfit your cleaning system with the perfect containers to enhance your washing workflows. Reduce your cleaning time and improve your product safety with a well-designed cleaning basket. Custom wire cleaning baskets from Marlin Steel hold delicate parts in just the right way so they won't scratch. Articulated parts can be washed better and gripped by robots consistently to improve throughput in a lean manufacturing environment.

Multiple varieties of industrial parts washer baskets are available, and the right one for you is dependent upon your specific application.

Marlin Steel's ultrasonic cleaning baskets are designed and engineered to meet your own custom needs. Each design is stress tested through FEA analysis to ensure its durability and ability to withstand ultrasonic cleaning conditions. We can add custom coatings, such as Halar and Teflon, to protect fragile components during the ultrasonic cleaning process. Our ultrasonic parts washing baskets are ideal for carbide cutting tools and stainless steel mesh filters.

Custom wire parts washing baskets for degreasing need to be able to withstand prolonged exposure to the harsh conditions this washing process uses. Baskets for parts degreasing are designed to be durable enough to endure both strong chemicals and high heat. That's why we run each basket through FEA analysis so each will work seamlessly during the washing process.

Marlin Steel's degreed engineers will design a custom wire tray or basket for your unique needs and aqueous washing process. Having wire applications created to fit your production process will help to improve your productivity and increase overall efficiency.

Proper sterilization practices are essential for pharmaceutical and medical washing processes. Marlin Steel's custom-manufactured stainless steel products for the medical and pharmaceutical industry include a range of sanitary carts, trays, and baskets that can all be electropolished to provide a microscopically smooth surface. Electropolishing helps to ensure that the part sterilization process is as thorough as possible.

Interested in improving your operational efficiency? Marlin Steel has a variety of dipping baskets for dye penetration applications. The degreed engineers at Marlin Steel can design dye penetration baskets for your unique needs and challenges.

Marlin Steel's ultrasonic cleaning baskets are designed and engineered to meet your own custom needs. Each design is stress tested through the FEA analysis to ensure its durability and ability to withstand ultrasonic cleaning conditions. Custom coatings, such as halar and teflon, can be added to protect fragile components during the ultrasonic cleaning process.

Custom wire parts washing baskets for degreasing need to be able to withstand prolonged exposure to the harsh conditions used in this washing process. Baskets for parts degreasing are designed to be strong enough to endure both strong chemicals and high heat. That's why each basket is run through the FEA analysis so each will work seamlessly during the washing process.

Marlin Steel's engineers will design a custom wire tray or basket for your unique needs and aqueous washing process. Having wire applications created to fit your production process will help to improve your productivity and increase overall efficiency.

Proper sterilization practices are essential for pharmaceutical and medical washing processes. Marlin Steel's custom-manufactured stainless steel products for the medical and pharmaceutical industry includes a range of sanitary carts, trays, and baskets that can all be electropolished to provide a microscopically-smooth surface. Electropolishing helps to ensure that the parts sterilization processes are as thorough as possible.

Interested in improving your operational efficiency? Marlin Steel has a variety of dipping baskets for dye penetration applications. The engineers at Marlin Steel can design dye penetration baskets for your unique needs and challenges.

Custom baskets fulfill applications in industries ranging from food processing and manufacturing to aerospace and defense. Common examples of custom parts washing baskets and their tasks include:

While multiple metals are compatible with cleaning basket manufacturing, 304 stainless steel wire for washing baskets tends to be the most popular. The material offers good tensile strength and resistance to corrosion, but it's a more affordable option than various other stainless steel alloys.

The material options we offer include the following:

To ensure you receive basket solutions tailored to your unique needs, our team is experienced in working with wire mesh, perforated sheet metal, and expanded metal options.

When you partner with Marlin Steel for your custom metal baskets, you can select from more than 40 different coating and finishing options to enhance their performance and aesthetics. Our mechanical engineers will help you find the ideal coating or finish for your project, with common examples including:

Maybe your current wire basket is no longer meeting your needs. Its design might not fit the dimensions of a new part you're working with, it can't withstand a new washing process or cleaning chemical, or your old basket might have sustained damage and you need a replacement. Alternatively, you're simply looking for something new and improved.

Whatever your reason for acquiring a new one, customized wire baskets tailored to your parts cleaning applications can lend your operations numerous benefits. Examples include:

At Marlin Steel, we have over half a century of multi-industry expertise in creating high-performance custom wire forms and baskets for a domestic and international client base. We combine a team of skilled craftspeople, extensive design and manufacturing capabilities, and automated equipment to create USA-made baskets that are customizable to virtually any component or cleaning process. We'll work closely with you to make sure we understand the material properties, resistance capabilities, design preferences, and other requirements that are necessary to guarantee success in your parts washing operations.

In addition to our design optimization, precision manufacturing, and 3D printing capabilities, our ISO 9001:2015 and ISO 13485:2016 certified company is experienced in various testing and analysis methods to ensure optimal quality in our custom products. For example, our team utilizes stress analysis to evaluate a product's performance in a predetermined load setting. How does stress analysis for custom parts washing baskets work? This process identifies potential failure modes so we can help you adjust your basket design accordingly.

We also use finite element analysis (FEA), which is a computerized method for predicting how real-world scenarios will impact your part or basket. The FEA method evaluates for exposure to vibrations, high temperatures, fluid flow, and more, helping ensure that your end product complies with all necessary industry regulations.

Are you ready to take the next step toward customized wire basket solutions with Marlin Steel? Reach out to our team with questions or to receive a free quote by filling out the form below.

Marlin Steel employs a team of seven degreed engineers. Available to assist with customer needs, this engineering team not only provides expert guidance but also ensures precision in every custom project.

For example, before completing any basket design, Marlin’s degreed engineers familiarize themselves with the application for which you’ll be using the baskets via your responses to a custom basket questionnaire. Based on your responses, the design engineer will modify a basket’s design, adding features such as lids, handles, and dividers, or changing the thickness and materials of your basket’s wire mesh to better withstand the stresses of your cleaning process.

With a Marlin Steel wire basket, you know that your basket was engineered with quality in mind. We manufacture baskets with precise factory automation techniques and equipment that ensure consistency from the first custom metal basket to the last so that all of them will work seamlessly in your wash process. Examples of our custom washing baskets include:

Every day, manufacturers throughout the world work to make sure that their products are ready for shipping to their final destinations. In many manufacturing plants, this means putting manufactured parts through ...

As a manufacturer, the struggle to improve productivity with fewer and fewer resources is a fact of life. To stay competitive, you need to get more done with less than the competition. This means finding ways to ...

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797