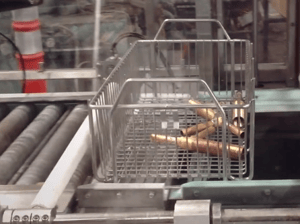

In ultrasonic cleaning, the container holding the parts can have an enormous impact on the effectiveness of the process. A poorly-made basket can result in damage to the parts being held, or interfere with the ultrasonic cavitation process and reduce cleaning efficiency.

In ultrasonic cleaning, the container holding the parts can have an enormous impact on the effectiveness of the process. A poorly-made basket can result in damage to the parts being held, or interfere with the ultrasonic cavitation process and reduce cleaning efficiency.

One question that many clients have about Marlin’s ultrasonic cleaning baskets is: “Why do you use stainless steel for your ultrasonic cleaning baskets rather than plastic? Are plastic baskets detrimental to ultrasonic cleaning?”

The short answer to this question is that stainless steel offers many advantages over plastic in terms of durability per cubic inch of material. However, there are also some advantages to using certain polymers in specific situations.

Good Points for Plastic Baskets in Ultrasonic Cleaning

One of the benefits of using a polymer material for the frame of an ultrasonic cleaning basket is that such baskets can be made mostly from a single injection mold. This minimizes stress and failure points, which makes the plastic basket a bit more resistant to being shaken apart during an ultrasonic cleaning cycle.

Another benefit is that plastic baskets often have a significantly lower surface hardness than steel. This makes it less likely that a plastic basket will scratch a part during ultrasonic cavitation than a steel basket would.

Finally, some plastic polymers may be more resistant to certain chemicals than their stainless steel counterparts. This helps keep the basket from degrading after only a couple of uses.

The Problems with Using All-Plastic Baskets in Ultrasonic Cleaning

While plastic baskets have a few advantages, they also have numerous disadvantages compared to stainless steel baskets for ultrasonic cleaning. These include:

- Inferior Overall Durability and Tensile Strength. While using a single injection mold reduces failure points, an underlying problem is that the ultimate tensile strength of most polymers is vastly inferior to most steel alloys. For example, grade 304 stainless has a tensile strength of 90 ksi (620 MPa), while a polymide and glass fiber polymer has a tensile strength of 150 MPa (or 21.75 ksi. Source: Matweb). In other words, the steel is over four times as strong as the “high-strength” polymer. Basically, any stresses that could bend a stainless steel basket would shred a plastic one.

- Surface Material Transfer. Although the relative softness of plastic polymers make them less likely to scratch a given part or product, they have a different problem: the transfer of particles from the basket to the held part. This can ruin the surface condition of a part—requiring reworking to remove the new contaminant.

- Open Space and Ultrasonic Vibration Interference. Due to plastic’s lower tensile strength compared to steel, the wires have to be molded to be much thicker than what could be achieved with steel. Using larger and thicker wires means more material between the ultrasound generator and the parts being cleaned—interfering with the cleaning process and making it less efficient.

- Chemical Absorption. Although some polymers are better able to resist degradation from specific chemicals than some stainless steel alloys, polymers are much more susceptible to absorbing chemicals over time. This makes it harder to clean the basket of excess chemicals. It also leads to discoloration and degradation of the basket over time.

- Basket Longevity. While not a factor that typically affects individual wash processes, the shorter useful life of plastic baskets adversely impacts their total cost of ownership (TCO). Also, if the basket fails mid-process, it can result in damage to the ultrasonic cleaning equipment and the parts being cleaned.

Basically, stainless steel baskets tend to last longer, interfere less with the cavitation process, and are less prone to failure mid-process.

However, it is possible to get the best of both worlds when it comes to scratch prevention and tensile strength by taking a stainless steel basket and applying a polymer coating to it. The strong steel core helps the basket maintain its shape, while the softer coating helps absorb impacts to prevent scratching. If the coating does wear down, it can be replaced as needed for a fraction of the cost of buying a whole new basket.

Which kind of basket is right for your ultrasonic cleaning process? Find out by contacting the experts at Marlin Steel with some specific details about your cleaning process and equipment!

Or, you can order an in-stock basket to suit your needs today!

.gif)