Marlin Steel’s engineering team have helped numerous electronics manufacturers improve their manufacturing processes for making printed circuit boards (PCBs) with custom steel wire baskets.

Marlin Steel’s engineering team have helped numerous electronics manufacturers improve their manufacturing processes for making printed circuit boards (PCBs) with custom steel wire baskets.

Recently, a manufacturer that was putting printed circuit boards of sizes ranging from 3/4” round to 15” x 19” contacted Marlin Steel for a custom PCB cleaning basket for use with a Technical Devices 800-series Nu/Clean aqueous cleaning system.

This cleaning system uses a mesh conveyor belt to carry the basket (and the parts it holds) through a multi-stage automated washing process. The solvent used in the aqueous wash process would be a relatively mild, pH neutral solution applied to the basket and its contents at a continuous operating temperature of 145°F for ten minutes at a time. Part of the drying process would expose the basket to temperatures of 220°F for another ten minutes.

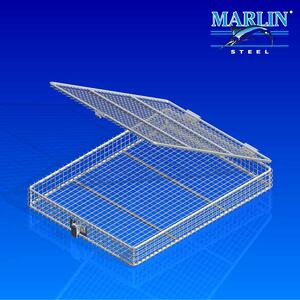

Because of the lightweight nature of the client’s PCBs, the heaviest load the basket would have to hold was estimated to be 10 pounds in a 20” x 20” x 2.5” area. The height of the basket had to be kept as low as possible, since the opening of the cleaning system was only 3.5” tall and there needed to be room for a hinged mesh lid on top of the frame.

Overall, the process was not too harsh compared to many of the others that Marlin’s engineers have had to contend with—which made sense, given how delicate printed circuit boards can be.

The biggest challenges in this design were the incredibly small size of some of the client’s PCBs, the short height of the cleaning machine’s opening and the need to make the process as efficient as possible. Here’s how the Marlin team overcame these challenges:

Building a Better PCB Washing Basket for the TD 800-Series

For this particular wash process, grade 304 stainless steel was determined to be more than tough enough to survive continuous exposure to the pH neutral aqueous wash mix. The tensile strength of steel would also allow the design team to make the wires extra-small with tight spacing so that it could hold the client’s tiniest printed circuit boards without letting them fall through—but also making sure that the fluids from the aqueous wash cycle could pass through with ease.

To keep boards from falling out during any agitation or high-pressure spray cycles, a latched lid was incorporated into the design with wires just as thin and tightly-spaced as the main body of the basket.

A set of cleats at each end of the basket’s bottom were added to help it better grip the conveyor belt—making it easier to load the basket into the TD 800-Series consistently.

To save space and make it easier to move a lot of baskets at once, the basket was made to be stackable when fully loaded—the cleats would slot into the basket below to let them stack neatly. Because of their relatively light weight, the fully-loaded baskets were easy to stack on a pallet for movement to the next process.

Before moving to full-scale manufacturing, the basket’s design was run through a finite element analysis (FEA)—a computer simulation program that tested the effects of the different physical stress factors on every last square inch of the basket’s design. This FEA would help highlight any potential issues so they could be fixed prior to the actual production of the basket.

Here, the FEA was used to help determine what the most efficient design would be—so as to avoid over-engineering the basket beyond what the client needed.

The End Result

Marlin’s engineering team was able to quickly finalize a design and tool some wire bending and welding robots—taking the design from concept to finished product in under a week. The PCB baskets helped the client to reduce their scrap and reprocessing rates—saving them money while also improving product throughput for their manufacturing process.

By learning about the specifics of the client’s production process, Marlin’s design team was able to create the perfect printed circuit board basket to help them increase efficiency.

Find out how you can get the perfect custom wire basket for your needs by contacting Marlin Steel today!

.gif)