Eliyahu M. Goldratt was an Israeli physicist, business consultant, and author who revolutionized the field of business management with his Theory of Constraints (TOC) framework. Born in Israel in 1947, Goldratt studied physics and received his Ph.D. from the Technion, Israel's Institute of Technology. He then moved to the United States and began working in the field of business management. Goldratt's breakthrough came in the early 1980s with the publication of his book, "The Goal," which introduced the world to the Theory of Constraints.

The Theory of Constraints is a framework for identifying and resolving bottlenecks in business processes. The theory holds that every system has at least one constraint, which is the factor that limits its performance. By identifying and resolving these constraints, businesses can improve their efficiency and profitability. Goldratt's approach was revolutionary because it challenged traditional management thinking, which emphasized maximizing the efficiency of each component of a system rather than the system as a whole.

Eliyahu Goldratt: How many of you have read my first book, The Goal? Oh, lovely. Now, I have a little bit more irritating question. How many of you had the read The Goal said it's common sense? I hope it's the opposite of the common practice. And then how many of you had the courage to go and implement the ideas presented in The Goal? Raise your hands now. You see about 15%. Oh, it's becoming better and better. I believe that now something like 20% of all the manufacturing in the world are using The Goal extensively. But still, let's go and ask a little bit more. People here have raised their hands when they said you had the courage to implement. Anybody here? Do you still have the courage to raise your hand? Yes. I don't know anything about this person, this gentleman. I don't know what is manufacturing. The only thing that I know is what he told us, which is he read the book and he implemented some of it. And that's enough for me in front of all of you to ask him the following. Did you got results?

Audience Member: Yes, I did.

Eliyahu Goldratt: Can you share some of those?

Audience Member: Sure. I actually did it in the financial services industry, not in manufacturing. Uh and we reduced our um cycle to market by about uh from 18 months down to about six months.

Eliyahu Goldratt: Not bad for a start.

Audience Member: Got me a promotion and a raise in a nice nice corner office with a beautiful view of downtown. So I was happy.

Eliyahu Goldratt: I can imagine. Have you noticed what you've just seen? Everyone that tried to implement these concepts have got results. Every single one throughout the world. What you have to realize is I left the university from physics and jumped into the world of management back in 78. Yes, I am an old man. Do you know what's really meaning old? In the morning when you're bent down to tie your shoes, you say to yourself, "Okay, since I'm down there, what else can I do?" You become more efficient. I wrote The Goal in 83 based on the works that I've done since 78 which means basically The Goal is the first years of my the fa first five years of my work and at that time what I've done and still do is I took the concepts of physics the approach of physics and I applied it to not the material world like physics or chemistry is doing not to atoms or electrons or molecules or enzymes but to human relationships to organizations. Yes. When I started, people told me Ellie, you are totally out of your mind because people are not predictable. And I've said really, I think that I can predict very well what will happen to me if I'll tell my wife my true opinion about her new dress. What do you mean people are not predictable? If people are really not predictable, there is no base for society. There is no base for family even. Yes, people are not 100% predictable, but so is the weather. Why won't we take this rigorous cause and effect thinking, this demand for prove what you are saying and apply to the social world. The Goal is a result of the first five years of my work and then I continued on. Of course, the big awakening of the conceptual mistakes that I'm doing came just in the last 10 years. And it came from my interaction with Japanese companies. Between me and you, Japanese are from another planet. It's unbelievable. And it takes so long until you learn how to communicate with them. Otherwise, it looks to you as if you're talking to aliens. From my learning about Japan, I came to the conclusion that the Japan culture is such that they will adopt Theory of Constraints, my theory, much much faster than any other culture. For example, the biggest problem that I had was to make sure that as you improve, for example, in manufacturing and you get these enormous results and of course what is happening is that the constraint is moving out of manufacturing and then all the improvement does not translate into more money but to expose more and more excess capacity that you will never even think on laying off the people that helped you to improve and now they are in excess. And I went out of my way to say, look, do you agree with me that the long-term success of a company depends on the loyalty of the employees? Yes or no? Hello everybody. Do you also agree with me that loyalty is a two-way street? Yes or no? Fine. So don't even think of laying off the people that help you to improve because that will be the end and that's what happened so many times. So when I've explored Japan and I understood to some extent their culture, I understood that Japanese company will not even dream on laying off a person unless this person is a jerk. But never to release to to lay off people just to improve the bottom line. never ever at the same time I was fully aware to what extent the manufacturing in Japan is so much more advanced than the western world and that's why there is such a trade imbalance and I said if I will go to Japan and release my ideas and if my speculation is right that their culture is like fitting like a glove with what I'm saying then I will increase even more the trade imbalance and everything will go down. Maybe it's mealomaniac, but I say I can wait for my royalties. And that's why until year 2000, I did not allow my book to be translated into Japanese. At the year 2000 or thereabout, I came to the conclusion that the gap is totally closed. And that's when I've allowed my books to be translated to Japanese. And yes, uh, Japan is going on TOC much much faster than any other culture to the extent that my books are sold in Japan more than the rest of the world combined. Just to tell you what's the meaning of it, my books are sold in Japan more than Harry Potter. Not that I'm complaining. But then I started to be called into Japan. I was talking more and more. Strange things have happened. I'll give you an example. Few years ago, I'm in Japan and my director in Japan is telling me, I would like you to fly tomorrow to that and that island. And I said, "Forget it. I'm I don't like to travel too much and I spending all my life in the airplanes." An hour later, Wendy, my assistant, came to me and said, "Ellie, you are flying tomorrow to to that island." I said, "Okay, you see, I'm a very, very trained man. I know with whom not to argue." Next morning, I'm there going out of the aeroplane. And my god, what's happening here is the governor of the town and the whole orchestra and all the journalists and they are telling me you have saved the capital of the island. Ladies and gentlemen, I don't know even the name of the island. What do you mean I saved the capital of the island? Turned out the following. This island is a southern island. It's very very mountainous. So every year when the typhoon comes around September, it hits the mountain and it cause a flood. The flood is not of water. It's of rocks and and dirt and so on. So when the flood comes out of the mountains to the valley, it wipes everything. You understand what I'm saying? So what are they doing? If the bottleneck of this when it comes from the mountains, they're building a dam to stop the flood. If the dam holds, everything is fine, but of course the dam is now full with rocks and mud. So next year they have to build a dam. And next year they have to build a dam. And if they don't succeed to build the dam in the right to the right time and the typhoon hits, they can tell you how many people will die and what will be the damage because in about one in 10 years it happens. Of course, who is putting the dam? It's a ministry of infrastructure. This ministry is the largest in Japan. You have to understand Japan is one quarter of a percent of the world uh surface the world land but it's 25% of the natural catastrophes. We just got a reminder a month ago and because of it they have to rebuild Japan all the time. No wonder that the largest ministry is a ministry of infrastructure. uh they are putting about 30,000 projects a year. Uh of course it's private industry that is doing the work but it's government projects. On these projects 6 million people's are people are working 6 million out of 130 million includes infants as well. Okay. So we understand how huge it is. So they're getting the best graduates from the best universities to go into this ministry and then they go up and up and up and then they go to jail. So what happened is that the two top guys of the ministry in charge of this island went to jail in September and due to that in December they didn't started yet to build the dam and they knew it's too late because a typhoon hits usually in September. out of desperation they decided to uh use the knowledge that I've published in the book called Critical Chain. by the way how many of you have read Critical Chain? much less unfortunately. Critical Chain for projects is what The Goal is for manufacturing. by the way how many of you have read Isn't It Obvious? almost nobody. My god, Isn't It Obvious to retail is what The Goal is for manufacturing. For heaven's sake, the whole world is not just production. Okay. Anyhow, they decided to uh use these ideas and the dam was standing finished in the first week of July. What happened by fluke is that the the typhoon hit the uh island the earliest in recorded history in the second week of July. So everybody said it was obvious to them that if they would not have used Critical Chain the flood would have wiped the uh capital and that's why I saved the capital. Fine. As a result of that, by the way, what happened is that today all the projects of the erh the ministry of infrastructure—all 30,000 projects every year—are done on Critical Chain. all of it. And in order to ensure it what the government have done is they said every time that a contractor can prove that the task that penetrates the most into the project buffer—and this sentence has a meaning only if you are on Critical Chain—if they can prove that the task that penetrates the most into the project buffer is held by the government for authorization or whatever the government will rectify it within 24 hours. So now if you are contractor you don't have a choice but to go on Critical Chain. By the way, in order to really honor their commitment of the 24 hours, all the engineers of the MLIT became specialist in the thinking processes of TOC. So they can react so quickly without creating a problem. Why do I tell you all of that? In order to tell you what happened to me in terms of realizing where do I go astray? I'm in Japan. finished all my meetings. I want to go back home but the flight is only at the afternoon. So what do I do this morning? I'm asking Wendy and Wendy tells me Ellie there is a two days workshop or seminar here in Tokyo where it's all the top companies in Japan and they're sharing experience with each other on their work with Critical Chain because we know that developing new product is a project. So are you going willing are you interested to go and hear it? I said of course. So I went there with interpreter. Always go with interpreter in Japan because even if they talk English, you don't stand the chance of understanding what they talk. And I'm listening to the first presentation, if I'm not mistaken, it was Panasonic talking about their experience with Critical Chain. And then the second presentation and then the third presentation each one by another huge company. And after the third presentation I cannot hold myself anymore. And I say may I ask a question say of yes of course and then I said and listen very impressive. Where are the results? He said we told you the results and I said maybe you see when I'm in Japan I'm really becoming polite. Then maybe you told me I didn't understood. My fault. Remember I'm an Israeli. Okay. And then I say okay maybe I'm not understood at all. So for example have heard it how many projects now you are completing on time? how many more projects you're completing with the same people. That's what I want to hear. I said that's what you mean results. Can you imagine that's what you mean results? And then one by one these presenters are going back to the podium. Turned out that they have the slides with the results that I'm talking about. Yes, we are now completing from 50% on time to 90% on time. Yes, we are doing now with the same people 30% more projects. all these standard results that I'm expecting when people are using Critical Chain. But then thank God I had the smarts to ask, wait a minute, you said that you've told me the results before you showed me these slides. What do you call results? Do you know what was the answer? The real result is that people motivation went up. to what extent the collaboration between people went up. That's what we call results. Fellas, isn't it strange? At the same time, I continue to peer and what this claim is the following. They said if people motivation is up, if collaboration is up then the the what you call result will follow for sure. But otherwise we don't care what financial results you have it will go down. Who is right? Us or them? Hello. And then I started to look more into the thing that are the soft side motivation collaboration. You see I'm a physicist. So I'm almost conditioned that what cannot be measured is not a science. Can you measure motivation? I discussed it is my wife and she said Ellie how much do you love me? 7.16. You're going to tell me that love between us is not important. More than that, you're going to tell me that you don't know when love goes up or down, even if we cannot attach a number to it. And that's when I start to realize for heaven's sake, they are right. And then the next question was wait all these companies are reporting huge improvement in this soft sites in my today are not soft anymore they are the hardest motivation collaboration all of these this is for me the hardest thing they're talking about huge improvements from what I wrote how come I haven't looked on it. And then I start to realize I started to realize that the most important thing in the success of a company is the human relationship. And the things that drain the most management time are friction inside the company. And the things that cause so many fires are miscommunication inside the company. So these are not a trivialities. This is really the things to take care of. And then I start to realize more and more to what extent we as management put the engines of disharmony inside our own company. In what way? We allow conflicts to continue to be inside our company and we think that it's okay to continue to struggle with unacceptable compromises and that's the killer. For example, if you are manufacturing, how many of you are struggling in the conflict of decrease inventory, increase efficiency without even realizing that this is an inherent conflict? Is it understood? Yes or no? Hello. Let's take the uh project environment, the multi-ro environment as an example. And I will ask Wendy to read a little bit from the forward to my book, The Choice, which I believe is the most important book that I ever wrote. Uh the forward to the Japanese edition.

Wendy: Put yourself in the shoes of a person who's in charge of delivering a task in a project. Even in the western industry, the allotted time to complete this task is not dictated from above. Rather, your boss approaches you and asks for your time estimate. Of course, being experienced and therefore well aware of the uncertainties involved in doing the task, you have to consider that not everything will go smoothly that you will encounter some difficulties or even more likely some distractions. Uh it depends. You try to explain to your boss...

Eliyahu Goldratt: for you each one of you. Okay, you've gone through the same experience. Okay, here's a project. This is your responsibility. Your boss comes to you and say how much time it will take. What is always your first answer? Always it depends. Now show me a boss that says fine. No, he will insist on a number. What I'm talking about here is across the world uniform. Am I right? Yes or no?

Wendy: It depends. You try to explain to your boss, but such an answer is not good enough. Your boss insists on a numerical answer. Now, would you give an estimate that you have a high chance a chance of let's say 50% of missing? Not in the Western culture. My impression is that being regarded as a reliable employee is even more important in the Japanese culture. So being pressed for a numerical time estimate, you don't have any choice but to add safety to your estimate. to choose a number that you think you have a reasonable chance of meeting over 80 or 90% depending on your personality and your company culture. After some negotiation with your boss, you settle on a number. You are aware of the negotiation and probably took this into account when you made your estimate. Now take the more common case where the surprises were not too big. The case that has about a 70% chance of happening. In this case, you will be able to finish considerably ahead of time, ahead of your padded time estimate, and proudly announce early completion of your task. But what will be the repercussion the next time an estimate is demanded from you? Isn't it more prudent to invest more time and do a thorough job to make sure that everything's properly checked? In short, to use all the time that's available rather than rushing to deliver ahead of the committed time.

Eliyahu Goldratt: Look how much time it will take to complete the task. There is no numerical answer. If you are looking on it scientifically, how much time it will take time to complete task. It's a matter of probability. If you are talking about something environment which is very well known like productions that you've done the same thing thousand times then the probability looks something like this correct still when you're saying it will take an hour it can take 50 minutes or it can take an hour and a half okay it's some probability what is situation in projects where the unknown is huge. The bigger the unknown the more the graph looks like that probability the time looks something like that with a very very long tail. Am I right? Yes or no? That's reality. Yes or no? Fine. But now wait. Let's check something else. A person said that it will take 15 days or whatever number. Now let's check how much time it really took relative to the time that was estimated. And now let's plot it. What do you see? For example, if here the 15 days, what you will see is that reality how much time it really took is something like that. Hello, we changed reality. Self-fulfilling prophecy. Am I right? Yes or no? This shows you to what extent this happens that if I give it time, even if I can finish before, I will not finish before I will do a better job. Yes or no? Okay. Now let's let's understand the real precaution because what I was looking before is just that if this is a median and this is a time estimate all this time was actually wasted. Is it understood? And that's what I can get. That's not the issue. Let's look on the real issue. Take the more global look on the situation with such type of behavior. What type of relationships? How much mutual trust do you expect between management and their direct employees? Hello. My boss asked me for the time. I'm giving the time we negotiate. He knows that I know that he knows that I'm lying. This is called trust. Ladies and gentlemen, that's our reality. Will you please wake up? Is this a correct way to run business? Wait, let's look on something else. Do you understand why it happened? Why did it happen? By the mere fact that you are asking me for a number and then I know that you will turn my answer into my commitment. You have put me in a conflict. Is it understood? Yes or no? And as a result of a conflict we are getting such relationships. Let's look on look at another example. Now put yourself for example in the shoes of a project leader. You want to do a good job to make sure that your project will be on time, within budget, and delivering all the promised content. But in a multi-project environment, you are not in charge of the people who do the actual work. They're also working on other projects. Is it understood the common practice in multi-project environment? Your only way is to approach their boss, a resource manager, and to convince him to put his people on your project. Well, how are you going to do that? How? You must give him the impression that your project is the most urgent or the most important project. In other words, lie. And bear in mind that all the other project managers are doing the same. The bastards. What type of relationships? How much mutual trust do you now expect between the resources and the project managers? Don't you see what we've done? We put people in conflict between their responsibility and their authority and we live with the compromises but we actually these conflicts are constant engines of disharmony. Hello. This is a big biggest killers. And when I start to realize that started to dive more and more, I found something that was a little bit disturbing. You see, as a scientist and all my work from the beginning was to realize that the our perception of our reality as a non-scientist is wrong. For example, I'm coming to a company and say, "What's your problems?" Don't worry. One of the biggest talents of every person is a talent to and moan. So, here it starts. And you get the list of problems, enormous list of problems. We in TOC don't call them problems. We call them undesirable effects. And now you have 50 of them different problems. And with more people that you talk, the more the list becomes longer. It's not so easy to show to people what every scientist takes for granted, which is these are not in a totally undependent problems. They're all interconnected. And if you really rigorously do the cause and effect between the problems, you will find out that all the problem without any exception are all coming from one core conflict. Hello. Unfortunately, we never address a conflict. We are just trying to move on the com the compromise point which means we are moving from one idiotic scheme to another. You want an example centralize two years later decentralize year later centralize. And if it really become bad every six months pluck pluck pluck pluck. We just replace one set of undesirable effect with another now nobody knows even where the toilets that's helps a lot and that's what I see over and over and over again. You see this analysis of what I've just told you about Critical Chain is what there's so many different conflicts. The whole idea is don't deal with them just one by one. Let's identify what is the core conflict that governs all the problems and there is always one always just one conflict that governs it all. But then what was the amazing thing for me to realize the way to break to eliminate this conflict there is only one way which is for lack of good words I will use here the work that was published by two professors from Europe. Fantastic work was published about 10 years ago. How many of you have read a book called Blue Ocean? Not enough. What they claim is the following. They claim that almost all companies are operating within red ocean. What's the meaning of red ocean? It's red from the blood that each one is eating into the other. That's a red ocean. And what they claimed that in reality there are companies who succeeded to curve for themselves a blue ocean. Blue ocean means you are satisfying a market need in such a way that the competitors are irrelevant. Hello. And what they showed case by case something like 30 different cases of companies that succeeded to do it. And these companies are really in a different shape. The only problem is that when you read this book and these two professors are really honest, they also tell you these companies that achieve the blue ocean were not the first one to come with idea. They were number 40, 50 and the first one to come with idea are bankrupt. Why? They don't talk. But if you really analyze it, you find out the way to curve a blue ocean is to satisfy a significant need of your market. Not a triviality, but something really significant to the market to the extent that no other competitor can. Then you are curving yourself a blue ocean. Many times when you came with this idea turned out that the need that you have satisfied is a baloney. It's not a real need of the market and of course if you'll go in that direction you're bankrupt. The real problem is that even when you have identified a real need and you are able to satisfy it not always the market recognize it as a real need. And then you'll have to go and educate the market. This is not a triviality. So the first one to try it will bankrupt and the second one bankrupt and the number 40 will build on all the efforts of all these previous and make a bonanza. What I found out and now what I'm telling you is based on enormous amount of experience. There is always a way to curve a blue ocean very quickly. In other words, to identify a real need of your market which the market is fully aware of. So you don't have to educate the market and to satisfy to the extent that no other competitor can and by that you are immediately into the blue market and it's always possible. The real thing is for heaven's sake that's the only way to break to eliminate the core conflicts that otherwise will continue to constantly erode the human relationship in the company. Now I know that what I'm telling you now is a little bit on the verge of impossible right? Yes or no? Hello. So let me show you to what extent the blue oceans are so open wide and just waiting for us. Let me take one two examples which are broad enough to show it to you. Suppose that you are in a company that produces projects to the outside world. construction, special equipment, it special projects, tailored project to the outside world. Okay? And you go to these companies and say what is number one factor in selling or not? And they will tell you price price correct or not. Hello. Let's take one example that we've done in full. So the example is here's a company which is the world benchmark—an Indian company that produces the core of refineries among other things. You know what's a core of refinery? These things that breaks the molecules. This is not a cheap thing. Okay. The core of a refinery is usually going for depends the size of the refinery something around $70 million. Okay. It's not something cheap or whatever. As they say, it's price, price, price, price. To the extent that every time they have an internal debate, should we reduce the price by $1 million and then we can win the bid? But then if we reduce it by $1 million, do we want to win the bid? It's so tight. And what he say is the following. All the expertise needed, all the quality, this is taken for granted. If you don't have it, you are simply not a player. So what we are really fighting on is a price. Understood? Yes or no? Now where the blue ocean? I've talked with all their top managers for days. And this was a starting point. Then I said, wait a minute. Let's look in reality as is your client when he decided that he wants a new refinery and then he put the bid in the market. What was his only criteria to decide I want a refinery? What was his only criteria and you all know it? It's return on investment. Am I right? Yes or no? Everybody understands it in full return on investment. But now what you're telling me is that when this same company same client is talking to you the supplier all of a sudden it's just price price which means all of a sudden is just investment as if the return is not part of the equation correct or not why let's understand a little bit better look on it that's a project here is a decision that decision is made based on return on investment period. Am I right? Yes or no? That will be the time that the project is completed. In other words, only after that the return will start. Up to there, it's the investment is going in. But now look where is interaction with the supplier. It starts sometime after the decision and it ends when the project is completed. You see the entire interaction with a supplier is in the section that the investment is dominant. Is it understood? Yes or no? No wonder they talk to us only about price. But don't you see what is a hidden assumption that both the supplier and the client are making. The hidden assumption is that the supplier cannot affect the return. Is it correct? For example, I've asked this company, how many times does it happen that the refinery is not ready to refine at the stated completion date? How many times there is delays? Do you know what was the answer? They know about one case, one case that it was starting on time and by the way in that particular case they were not the supplier. Then I asked them what's the average delay? Huge debate took time. The answer was we cannot agree between us but the average delay in this case is between four and six months. That's the average delay. Then I said fine what's the impact on return to the client? And their answer was we don't know. That's where I've started to lose my patience. What do you mean you don't know? That's your business. They don't know. there are only 30 years in this business and then I said okay first of all I had to control myself and then I said do you know when you are starting when you're even submitting the bid do you know how many barrels a day the refinery is supposed to refine and the answer was of course otherwise how can we plan it okay that's the parameter that tells us what to build. Said, "Fine. So, you know how many barrels per day?" Fine. Do you know also how much the client is making per barrel when he refineses it? And I said, "Of course we know." Well, it's depending on the price of the oil, but it's somewhere between $2 and $4 a barrel. So, so you know that as well. Now, I have a real question for you. Do you know to multiply number of bells per day times what the client is doing net per bell here is a damage per day of a delay multiplied by minimum four months. Look what you are getting. It's more than the entire cost of the project. Hello And you are fighting on 1 million or not in in your proposition because you are fighting on cost on price. What will happen if you will gear all your operation to dramatically improve your performance so that you can guarantee that you will deliver on time. Don't you understand that? Then you are in a blue ocean. Hello. Are you with me? Yes or no? This is a need of a client that you don't have to explain too much. As a matter of fact, when you come and show it to the client, the only thing that the client is saying is, "I don't believe you. It's too good to be true." As a matter of fact, I'm talking to you only about price because I gave up on you. So, show me, prove to me that you will deliver on time. Is it understood? Yes or no? Do you understand that here is a generic way of how to create blue oceans? When we're talking about projects, what you have to realize is how am I as a supplier can affect the return. Aim all your improvement projects to be able to do it. But then you are in a blue ocean. Am I right? Yes or no? Hello. Let me give you another huge example. You're a manufacturer and you sell to wholesalers or to retail. This is a huge section of of business. Am I right? Yes or no? And once again, go and talk with your salespeople. Price, price, price, price, price, price, price. What is the most important thing for wholesaler or retail? Is it price? Think again. It's not price. Think again. And for that, if you are manufacturer, you will have to think a little bit more to understand what's the meaning of your clients because it is amazing to what extent. We are doing business for dozens of years and we still still don't know the client understand the clients at all. Look on the huge difference between a manufacturer and a wholesaler. Two huge differences. One is how much of the cash of a wholesaler is tied up in the inventory? How much? Come on. Come on. You all know it's well over 90%. This is not the case for manufacturer. Not that inventory doesn't capture a lot of our cash, but not 90%, not even 50%. We our cash is tied up in machines and so on so many other things. But for a wholesaler almost all his money, all his cash is tied up in inventory. That's one difference. Now comes the second difference. If you're a manufacturer and I will come to you and say, you know what, I will arrange for you unlimited line of credit. Unlimited. Can you double sales in one year? And your answer most likely will be no way to double sales in one year. I need more clients. I need more new products. I will have to expand to other geographical areas. This is not done in one year. Am I right? But if I will come with the same proposition to a wholesaler and I will tell him I'll arrange for you for unlimited line of credit. Can you double sales in one year? What is his answer? No problem. I will just triple the portfolio of products that I'm carrying. I will easily double cells. Is it understood? Yes or no? And because of that, because of these two differences together, will you please start to understand that for a distributor or for a wholesaler, the number one measurement is inventory turns. How many times is turning the inventory? That's is a make or break. Is it understood? Yes or no? Now if as a manufacturer you will be able to come to a wholesaler with a proposition that increases inventory returns by even 20%. That's a very good proposition for him. If you can come and show that you will double his inventory turns, you're in a blue ocean. As a matter of fact, what's the reaction? The reaction is it's too good to be true. Let's try it on some excuse. You prove it, bingo. It's yours. Is it understood? Yes or no? In other words, it's not the difficulty finding blue ocean. It's understanding that that's the most important thing and now understanding how do you go about getting it what's internal improvements that we have to do so we can deliver it are you with me. In every field it's existing. let me tell you from my experience and my experience today is huge I haven't seen even one case that within an analysis of less than 10 days I couldn't pinpoint the blue ocean in a very realistic way and can could have been done and was done in most cases. Not even a single case. But why do I put so much emphasis on it today? Without the blue ocean, the core conflicts that govern your company is not removed. Which means we continue to have the engines of disharmony that ruins us. Is it understood? Yes or no? So if we really want an ever flourishing company, gearing all the improvements effort not in order to improve some efficiency or some cost but in order to get the blue ocean is not a desirable thing. It's a must. And then of course once you have that you have other problems like for example you will find out that once you have the blue ocean your sales people don't know how to sell it because they are totally conditioned on price. So you will have to go and learn new techniques like the one that was paved by spin selling which is a huge paradigm shift in the salespeople. Thank god the salespeople are not idiots. they can easily learn it. And once you are doing that, you will find out that you have a new problem. And what is the new problem? Cells are increasing so quickly that bottlenecks appear back in operation. Then you can crash yourself. So it's a matter of how do you do it prudently otherwise you will go from one ditch to the other. But it's all there and all can be done and more than that. So many companies have already done it and there is a systematic way to do it. Do you understand what I'm telling you relative to The Goal? The Goal was just the beginning. And as a matter of fact, when I'm looking now back on The Goal, what is written there? Yes, Alex Rogo have done it. By the way, it's not a novel. You all know that The Goal is based on real stories. It's real plans that emerged into this book. And after that, it was verified again and again. You know, I've got so many letters of thank you and so on. The letter that I cherish the most I received less than a year after it was published and it was from a plant manager in the United States and he wrote to me "Dr. Goldratt, your book is not a novel anymore. It's documentary because I have done exactly what you wrote and I replicated all the results. And the only difference between your book and my reality is that my wife didn't came back yet." But even then, look what happened. They improved operation so nicely. The constraint moved into the market and now by fluke they got one big order. Let's celebrate and what will happen next month where the fluke will come again. In other words, what we're talking about is let's do it systematically so that as we improve, it's not just improving the bottom line. I don't care about that anymore. I'm talking about improving the stability of the company to increase it and increase it. If the stability is going up, if because of its motivation is going up, if the collaboration between our people will go up, the financial results are guaranteed. Is it understood? Yes or no? It's the opposite. That's what I want that you will go out. And for heaven's sake, it's all common sense. What is my problem with you? Outside this science world, somehow we have the admiration of sophistication. The more sophisticated it is, the more respectable it is. And if it's sophisticated to the extent that we don't understand it, then it's gorgeous. Where the hell is it coming from? Are you aware that in the whole sciences it's the opposite? Let me try to explain it. You probably know that the wet dream of every physicist is the Nobel Prize. To get the Nobel Prize, you have to publish one single article. That's enough. But the article must be on the level that when any other physicist reads it, his reaction is, "Oh that's a Nobel Prize." Fellas, that's the hardest things that exist—to look on realities that look so complex and to find how to understand it so it's so obvious that you will call it common sense. That's the harder thing to do, but that's the only thing that works. Am I right? Yes or no? And that's what you have to learn how to do. And that's what I'm going out of my way for heaven's sake. Enough with this sophistication. Let's learn how to create common sense. Let's learn to respect each other. Let's learn that our people do not behave so nice as we want because we have allowed the conflict to continue on. We are causing it with our own hands and we are the ones that don't listen. We have good reasons. For example, you come with a idea, you thought it out, you really know. You come with idea. How many of your people will react with "yes but"—usually very small "yes", big "butt". How many? How many? All of them. And then we try to listen and we try and then we lose our temper and we start to attack or at least me. Huge mistake. Look what's happening. We are making two mistakes. One is we are grossly underestimating what fantastic intuition people have and the other one is we grossly overestimating ability of people to turn their intuition into words to really express what they are talking about. For example, look what's the meaning of "yes but"—yes to some element of your suggestion of what we should do. Yes, we'll do that. But then what does it mean? He said if we'll do that since this exists as well the two together logically will unavoidably lead to having that. If we have that since this exist these two together will unavoidably will lead to that and this is negative. This is the meaning of "yes but". is it understood? Yes or no? Unfortunately, when we listen to the person, we don't see it. What I'm begging you to learn, okay, is how to listen to the person and then from what he says, put this diagram, the yes or the logic to the butt and then ask him, is that what you meant? You know what's usually is the answer? No. That's exactly what he said. It's not what he meant. But the minute that you show it so clearly, he is now able to really verbalize his own intuition. And then he you have to still convert it into this precise logic. And then comes the hardest part of them all. Keep your mouth shut for minimum 60 seconds. If the person has this fantastic intuition that he was able to say the "yes but" the minute that it's verbalized so clearly he has also the intuition to come with the answer which is "ah so if we do that as well the negative will not come" and you will find out to what extent even if you have thought about it and addressed it the way that he have now suggested is much better because on that area intuition is better. Do you understand what I'm talking about? I'm talking about let's build companies. Let's change our companies to a place that it's fun to come to work. Place that is financially successful. Fine. But it's a place that everyone says instead of "it's Monday", he says "it's Monday!" Why won't we? All the goodwill is there. All the knowledge is there. Let's put it together rather than allowing some secret cows to stand in our way. And if you notice, if you read any of my books, it's all common sense. Hello. May I ask you a question? How many of you are interested to explore it further? Hi. Raise your hand high. Have you noticed people do not resist change? People judge a change and based on their conclusion whether or not it's good or bad, they will embrace it or resist it. Now I have another question for you. There are two ways to continue to explore what I'm telling you. One is a company can decides okay you and you go and explore it much further or a company can decide to explore it as a team. How many of you will not commitment will want to explore it as a team and how many of you will want to explore it through individuals? I want to know the composition. How many of you if you want to continue to explore it—which most of you won't—you want to explore it as a team? How many wait fine? How many will want to explore it by sending some pioneers to really understand it before we will put more? Both are valid. Okay, I will give you both options. First of all, to explore it as a team. Listen, I never gave this offer before. What I want to see is if we can move more than one company in the same area, can we then create a pocket that can change a country? Okay? And that's why I'm giving you this offer. So listen carefully. The offer is the following. Those of you that want, I'm ready to send an expert, a real expert to your company for two days. What this expert will do is the first day he has to meet with every top person one-on-one in order to really understand the company. Basically, in this conversation, it's not really a conversation. For example, you are the top guy that the expert meets with and he will ask you, "Come on, what's your opinion?" And you start to blah blah as usual. Don't worry. After about four minutes, he will stop you and say, "I want to really see if I understood you." He will take what you said and he will present it back to you as the conflict that is driving what you said. Okay? And he'll say that's what you are complaining about. Usually you will say yes but it's not all of it. And you will give more clarity and again after five minutes it will stop you again. write the conflicts that now encompass everything that you're saying and within three iteration you will ask them to get a copy of this uh conflict but that's the way to really understand what is really bothering you and to come to the core of it and that's what has to be done with every top manager okay. That now our person really understand your company the next morning it starts. Please let's start with a problem major problem. He will show you—the expert—how do you systematically convert it into the conflicts that cause this problem and we'll do it with you then another problem same process and then it will show you look these two conflicts are not the same but they have similarities. And then another problem and with the third conflict that you will develop with him, you will see now the striking similarities to the extent that you will be able to write the core conflict, the one that deals with everything. And then in order to verify it, he will write now the core conflict in expressed in sufficiency. "If that and that we must have that. If that and that we must have that and because of that and that we are having the conflict." Okay. And then he will give you the list the distilled list that he got from all the interviews. The next morning he will divide you into two groups and said okay now connect all of it to the base. Verify to yourself that all the complaints are coming from the same co conflict. And then each group presents and you will see to what extent they're basically presenting the same thing. In other words, here is a picture of your reality. Everything stems from one core conflict and here the core conflict and you yourself have done it. And then he will highlight to you what will happen if it would have come three years ago or five years ago. Will the complaints would have been the same? Basically yes. Will the call conflict be the same? Basically yes. which means for the five years you have dealt with "chip chicks." It's a slang in Hebrew. It's actually a Ukrainianish word. Now I'll define it. "Chupchick" means pissing in the wind and feeling very proud about it. "I'm improving. Look, I sent him two cents and my efficiency went up." same ditch. Either we solve the core conflict or we'll continue to run in circles and be in the mercy of external forces. Is it understood? Yes or no? Then once you see that you will be able to realize I better have a blue ocean because that's the only thing that breaks my conflict. And now if you want to continue on you know where to go. Is it understood? Yes or no? Of course you have to learn much more after that. But at least at that stage you have a full consensus of all management together because you all understand it's not that each department is dealing with another problem. And definitely not it's the other department which is the problem. Okay. It's one conflict that governs everything. So either we put all our minds together to eliminate it or we'll continue to be in the misery that we are. This is the way to go with a group. The other thing is pick one or two people send them to Israel to five days where they will see all the generic solutions and all the approach for five sections of the industry. make to order, make to stock, retail projects and erh uh equipment. Okay, in details and then of course you will have much more base to understand how well it's applicable to you. Both options are open to you. Now the price for the two days expert visit that will come to your company and of course you have to arrange it perfectly. I will not send my rare experts to be wasted. Okay. The price is cover his TNL. That's all. This is a gift for me. Don't worry, I will get your money after that. The price to send one or two people to Israel for 5 days to learn it all is you have to pay for their flight and for your for their hotel. I'll give it free to you the whole five days. Good enough? Good enough. Lovely. What I want to see is how many companies will move because if you will move in the first steps, you are not idiots. You will move all the way. But then if it is five companies at the same area, I believe that we can do the same things that we are doing in Japan—putting you together even though we are in total different industries and you are moving the whole area the whole country and that's what I want to see. What you don't realize is the center of consumption in the world is changing. Not that the consumption is going down in the US but the consumption in China and India is growing by more than 10% a here and China and India each one of them is huge one is 1.3 billion people and one is 1.2 two billion. You are not thinking this scale. Of course not me—I'm an Israeli. You know I'm coming to China and they say "ah where are you from" and I say "Israel" I said "ah we heard so much about you how many people are in Israel" and I say "6 million" and they say "oh in which hotel do you stay?" The consumption center is moving moving to China and India. China is a long time ago the biggest producer of the world. 9 months ago, China became bigger consumer than Germany. Two months ago, China became bigger consumer than Japan. Look on the graphs. Look on all the cause and effects. Five years ago, China will become bigger consumer than the US. This is good news. It means we have huge markets. New huge markets. The only problem is that you as an Americans don't have a mentality of export. I'm coming to a company in the US and say do you export? I said "oh yes we ship two orders last year to Canada." Fellas the consumption is moving. If you will allow it in the sense that you are still six weeks away from the new consumption centers, you will kill yourself. I'm begging for the last five years, Americans wake up as a national effort build the transportation fleet so that no matter where the consumption will be, you are only 24 hours away from it. six weeks away and this economy will start to realize what happened when you are an island. You are now the center of the consumption. That's why you don't pay attention to it. But when you are not the center of the consumption, will you please look on the globe? US is an island. Fine. I'm starting to preach which is bad. Please, let's start to move on common sense. Let's start to realize that we have built our companies not for next quarter and not for next year. Let's start to realize that we build our companies to be really proud of them, really proud of our company, really proud of our people. So things like motivation and collaboration and all of that are important by in their own merit. Definitely they are the necessary condition to get long-term prosperity and here is a way to reach it. Common sense way. whatever you know about TOC whenever you go into it and read another book your conclusion is still the same. It's common sense and talk with around you. Go on the internet and you will find out anyone that tried it got the results. So I do hope that you will take advantage on my offer to you of exploring it further either as a company or as a company but sending individuals. Both things are open to you for the next two months. I'm not asking you to make a decision now, but if you will not make decision on that within the next two months, leave me alone. Thank you very much for tolerating me. Thank you.

Goldratt's contributions to the field of business management did not go unnoticed. He was awarded numerous honors and accolades, including the title of "Father of the Theory of Constraints." Countless businesses around the world have adopted his ideas, and his books have been translated into dozens of languages.

But Goldratt's impact went beyond business management. He was a visionary thinker who believed that his ideas could be applied to solve some of the world's most pressing problems. He wrote about the potential of the Theory of Constraints to improve healthcare, education, and even the global economy.

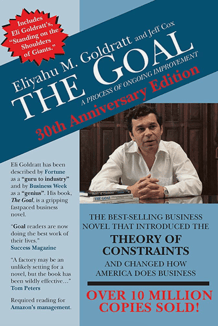

Goldratt's influential business novel left a lasting impression on Drew Greenblatt, Marlin Steel Wire President. Reading "The Goal" helped Greenblatt refocus his business and product offerings at a time when the Atkins diet popularity was soaring and demand fell for the company's wire bagel baskets. As chairman of the Regional Manufacturing Institute (RMI) in Baltimore in 2011, Greenblatt decided to invite the author to talk about his theories.

Goldratt visited RMI on April 14, 2011, giving a speech about the benefits of maximizing ROI rather than simply completing projects and the importance of developing human relationships and trust amongst your workforce. Greenblatt introduced Goldratt at the event as the man who "saved our company." Goldratt was so touched that, afterward, the author asked Greenblatt to join him in his limo. Goldratt used the ride to dissect Marlin's operations with Greenblatt and provide numerous suggestions for improvements.

Sadly, this would be Goldratt's last speech, as he passed away from cancer in 2011 shortly after his return to Israel, but his legacy lives on. His ideas continue to inspire new generations of business leaders and thinkers. At Marlin Steel Wire, we are proud to be part of the Goldratt legacy. Our commitment to continuous improvement and innovation is rooted in Goldratt's ideas, and we strive to apply his principles every day in our work.

The Theory of Constraints: A Powerful Tool for Business Success

The Theory of Constraints is a powerful tool for improving business performance. By identifying and resolving bottlenecks in a system, businesses can improve their efficiency, reduce costs, and increase profitability. But how does the Theory of Constraints work in practice?

At its core, the Theory of Constraints is about identifying the limiting factors in a system and then optimizing the system to remove those limitations. This process involves five steps:

- Identify the constraint: The first step is to identify the constraint or bottleneck in the system. This could be a machine, a process, or a resource that is limiting the system's performance.

- Exploit the constraint: The second step is to exploit the constraint by maximizing its efficiency. This could involve investing in new equipment, streamlining processes, or improving training for employees.

- Subordinate everything else to the constraint: The third step is to subordinate everything else in the system to the constraint. This means ensuring that all other processes and resources are aligned with the needs of the constraint.

- Elevate the constraint: The fourth step is to elevate the constraint by investing in new technology or resources that will increase its capacity.

- Repeat the process: The final step is to repeat the process by identifying and resolving the next bottleneck in the system.

By following these five steps, businesses can achieve significant improvements in efficiency and profitability. A wide range of industries has successfully applied the Theory of Constraints, from manufacturing to healthcare to education.

At Marlin Steel Wire, we are committed to applying the Theory of Constraints to our business. By continuously identifying and resolving bottlenecks in our production process, we have been able to increase our efficiency and reduce our costs. Our success is a testament to the work of Dr. Goldratt.