Welding is a critical process for manufacturing any complex custom metal form. Marlin Steel’s manufacturing team frequently performs welds with varying types of stainless steel to complete complex custom wire forms for customers.

Welding is a critical process for manufacturing any complex custom metal form. Marlin Steel’s manufacturing team frequently performs welds with varying types of stainless steel to complete complex custom wire forms for customers.

What Kinds of Welding Processes Are There?

There are a few different types of welding processes that Marlin’s manufacturing team uses. The two that are used the most often are:

- Metal Inert Gas (MIG) Welding. Also known as gas metal arc welding (GMAW), MIG welding uses a continuously-fed electrode wire that melts into the weld. This melted wire acts as a filler material in the weld—allowing two pieces of metal to be joined without having to heat them to the melting point.

- Tungsten Inert Gas (TIG) Welding. Also known as gas tungsten arc welding (GTAW), TIG welding has a non-consumable electrode that heats metal to the melting point so it can be fused directly. Requires strict control to prevent over-heating of metal.

More traditional welding processes using oxyacetylene torches are available, but not preferred for most of Marlin’s manufacturing applications. This is because these processes are much slower and less consistent than the arc welding processes listed above.

Many of Marlin’s clients have asked how Marlin uses MIG welding in the company’s manufacturing process. So, here’s a quick explanation of how to weld stainless steel with a MIG welder:

How to MIG Weld Stainless Steel

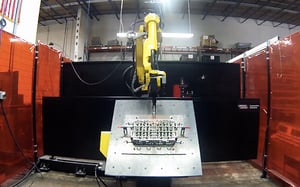

In most cases, MIG welding stainless steel wire and sheet metal forms is pretty simple for Marlin’s manufacturing team. The team programs a MIG welding robot to perform the weld and places the workpiece inside.

However, even this simple process has its complications. Some things that need to be considered include:

- Bracing the Joint During Welding. To keep the workpiece from slipping during the weld and ruining the angle of the joint, it needs to be properly braced during the welding process. Marlin’s manufacturing team typically uses wood blocks cut with a wood routing machine for this purpose.

- Distributing Heat from the Weld. If the heat generated by the welding process isn’t evenly distributed, it can cause burns, cracks, and other issues. Here, the mechanical precision and control of robotic welding helps by moving the welding arm quickly and precisely as the weld completes. For example, Marlin’s medium frequency direct current (MFDC) can complete welds in 2/1,000 of a second—minimizing the risk of weld spatter and other deformities.

- Choosing an Inert Gas Blend. Part of the arc welding process is choosing the right gas for the material being welded. As noted by Lincoln Electric, “You do not want to use a completely inert shielding gas, such as 100% helium or 100% argon for stainless steel MIG welding.” This is because the arc characteristics of the MIG process, which involves the use of filler, are markedly different from TIG processes—which would negatively impact the efficiency of the arc weld.

- Cleaning the Weld Joint. One of the side effects of using a filler material for a weld is that it can lead to weld spatter—even when using a fast and efficient welding machine. This spatter can become sharps or burrs on the weld joint which may cause injury to people handling the final product. So, to improve safety (and make the welded joint look nicer), a welded stainless steel wire form is often put through a secondary process such as sanding or electropolishing to remove these weld spatter sharps. The choice of process often depends on the application of the custom metal form.

By using the right techniques and equipment, Marlin’s manufacturing team can prevent weld defects from occurring in the custom stainless steel wire forms that they make.

Want to know more about how Marlin makes custom wire forms for manufacturers? Reach out to the Marlin team today!

.gif)