Marlin Steel specializes in making high-precision custom wire baskets for a variety of applications where parts tolerances are incredibly specific. Much of the time, when people think of applications with tight parts tolerances, they think of the aerospace, automotive, medical, or technology industries. However, there’s another industry that can benefit from precisely-manufactured custom wire baskets: the food preparation industry.

Marlin Steel specializes in making high-precision custom wire baskets for a variety of applications where parts tolerances are incredibly specific. Much of the time, when people think of applications with tight parts tolerances, they think of the aerospace, automotive, medical, or technology industries. However, there’s another industry that can benefit from precisely-manufactured custom wire baskets: the food preparation industry.

Recently, a major food maker that supplies ready-to-cook packaged food products for the restaurant industry reached out to Marlin Steel for a series of custom stainless steel wire baskets for use in their food processing equipment.

What the Client Needed in a Food Processing Basket

This client was a major supplier for chain restaurants across the country. The big draw for their products was that they were fully prepped before shipping—all their customers had to do was finish cooking the pre-measured portions of food to serve.

Because they had an enormous volume of business, they needed to ensure that they could process large batches of food products in their baskets with as little delay as possible.

Every piece of food in their pre-cooked meals also needed to be cooked to perfect consistency—after all, a variation in quality could negatively impact their customers’ businesses. Additionally, portions had to be strictly controlled and kept separate so no one batch of product was appreciably larger or smaller than the next.

On top of this, each basket needed to be exceptionally easy to clean and sterilize between uses to prevent cross-contamination of food during preparation.

How Marlin Made a Better Food Prep Basket

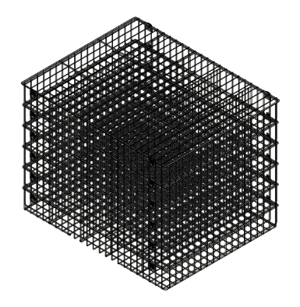

One interesting feature of the client’s food preparation equipment is that they had very large internal dimensions. However, piling meat or other ingredients in a single basket would keep these items from cooking evenly. To address this issue, Marlin’s degreed engineers decided to make a stackable basket.

The stacking basket would keep the food products separated by layers in ovens and other food processing equipment. To further separate food products, each basket was given a series of dividers. The combination of stacking and dividers helped ensure that each food product had plenty of space around it to ensure air flow for consistent and reliable cooking.

A lid was designed to cap the top basket in the stack so no food products would fall out accidentally during the preparation process.

To make the baskets easy to clean for reuse, they were made out of electropolished stainless steel wires. The stainless steel would prevent corrosion from exposure to various fluids from the different food items the manufacturer would process, and electropolishing the metal would create a microscopically-smooth surface that prevented food from sticking to it. Also, because of steel’s high temperature tolerance, the baskets could be sterilized using high-temperature processes—which made cleaning the baskets for reuse even easier.

The end result was a basket that:

- Made it easy to process large batches of food products at once;

- Was easy to clean off for reuse (minimizing the time spent cleaning baskets); and

- Minimized risk of food batch rejections.

Because of Marlin’s investments in manufacturing automation, each basket was able to meet incredibly precise parts tolerances so they could stack neatly and without issue. Additionally, Marlin was able to complete the client’s rather sizable order for custom food processing equipment baskets quickly.

Need a custom food processing equipment basket as soon as possible? Reach out to the Marlin Steel team to get a free custom basket quote!

.gif)