Marlin Steel specializes in creating custom metal Carts and Racks for a variety of applications. Every mobile cart Marlin creates is manufactured using advanced factory automation for a very high level of precision, so each cart is identical. From automated CNC press brakes, to laser cutters, to welding robots operating at 1,000 Hz for better welds, Marlin has the tools needed to meet millimeter-precise tolerances for your rolling carts—no matter the application. Additionally, our ISO 13485 certification ensures compliance with medical device manufacturing standards.

We have a variety of heavy-duty stainless steel carts with wheels in stock for rapid delivery to manufacturers throughout the USA.

Marlin Steel builds custom stainless steel cart designs for a variety of industrial applications, including:

Marlin can make heavy-duty industrial steel carts for moving large-scale loads. These carts feature extreme durability for surviving tough manufacturing environments, high tensile strength to handle heavy loads, and a combination of fixed and swivel casters for stability and ease of movement.

Using food-grade stainless steel, these rolling carts enable food manufacturers to easily move large loads while maintaining sanitary conditions. These mobile carts often employ additional polymer covers to keep airborne particulates (such as dust) from touching finished product.

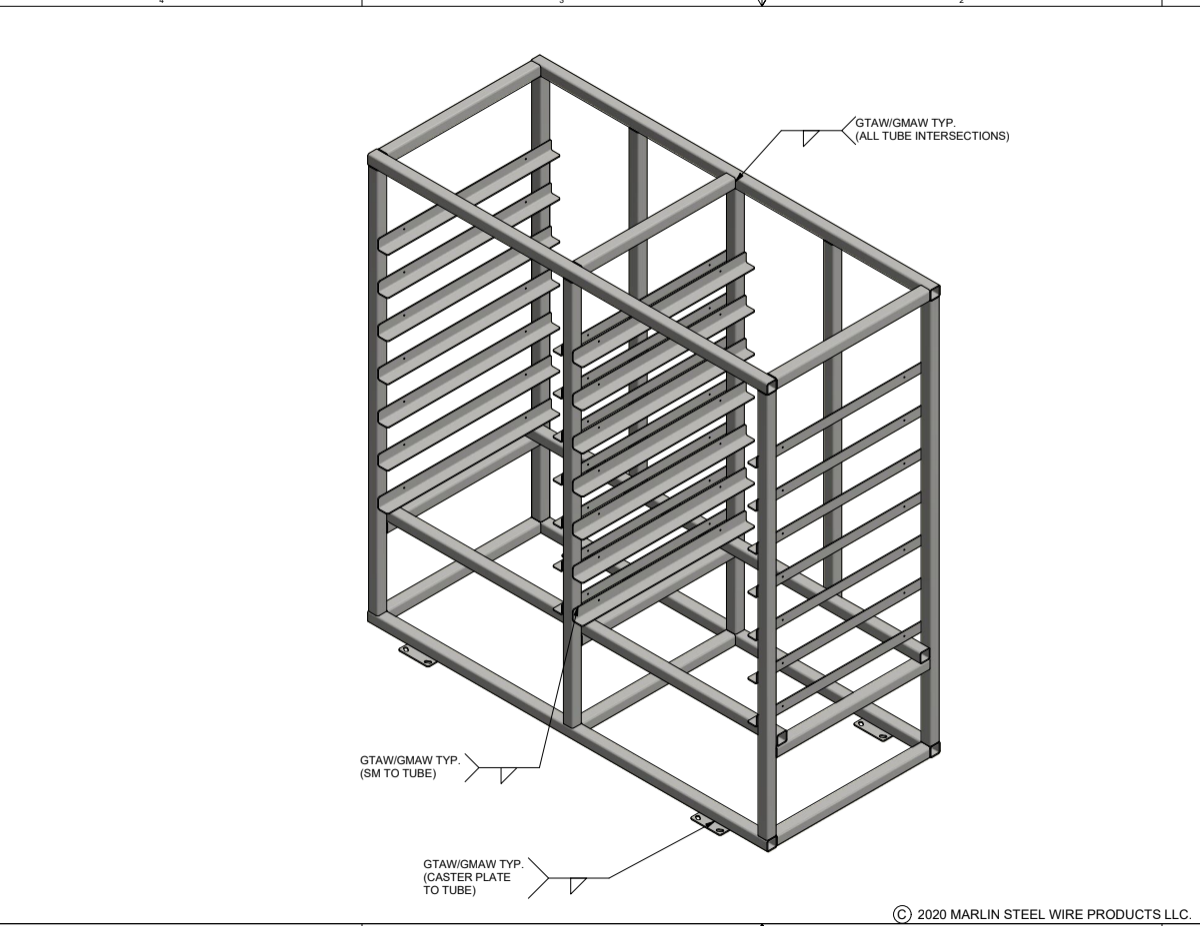

By maximizing space between held baskets or trays, rolling carts can help facilitate faster drying of industrial parts after an aqueous wash process. These carts are ideal for parts after both standard and ultrasonic parts-cleaning processes.

In addition to the stock carts that are available, Marlin’s engineers can create customized rolling carts to meet the specific needs of your particular industry or manufacturing process.

Each custom rolling cart order starts with a brief questionnaire to get the details of how you will be using the cart, including:

Based on this questionnaire, Marlin’s mechanical engineers will create a basic design, including material choice (stainless steel, plain steel, Inconel, etc.), coverings, handles, general frame size/shape, and wheel types used.

For example, hard polymer wheels are often useful for maximizing durability and useful life, while rubberized wheels offer better traction and control for ease of handling.

Once the design is completed, a CAD file is generated and put to the test using Autodesk virtual physics simulation software. These tests help identify any potential faults in the design or materials of the cart prior to mass production. Only after these tests are completed and any flaws are fixed does manufacturing start.

Marlin Steel carts can be used for many industries. Each cart can be customized with different parts, materials, and spacing to meet your unique needs. To start your custom industrial rolling cart order, fill out the form below or contact Marlin Steel today! Most custom orders can be completed within 1-2 weeks of their initial order date and stock carts ship the same day.

Looking for a price estimate or need help as you search for the right wire form for your needs? Submit your custom wire form requirements and a Marlin Steel expert will get back to you with a quote and more information!

CFM shafts used in aircraft engines can be notoriously challenging to move and store. Without careful handling, CFM shafts may incur damage as they ...

Learn More >>

2020 is destined to go down as the year of COVID-19. Now, 2021 is shaping up to be the year of the vaccine. The approval of multiple vaccines and ...

Learn More >>

Stainless steel is well-known for being resistant to corrosion from things that make plain steel and iron (and other materials) rust away. However, ...

Learn More >>Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797