A long time ago, Marlin Steel’s bread-and-butter business was the manufacture of commodity retail display wire baskets for bagel shop storefronts. Day after day, Marlin’s employees would manually bend and cut steel wire retail display baskets for bagel shops all over the country.

A long time ago, Marlin Steel’s bread-and-butter business was the manufacture of commodity retail display wire baskets for bagel shop storefronts. Day after day, Marlin’s employees would manually bend and cut steel wire retail display baskets for bagel shops all over the country.

However, Marlin Steel would eventually shift focus and start making high-quality custom steel wire baskets for manufacturers who needed precision-engineered baskets. Today, Marlin Steel frequently serves companies in the food industry with high-quality American-made steel food processing equipment baskets for a variety of specialty food handling tasks.

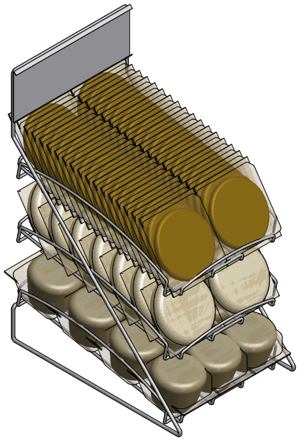

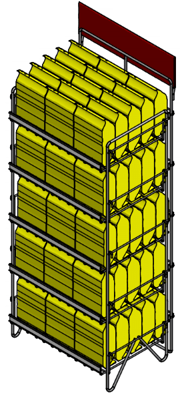

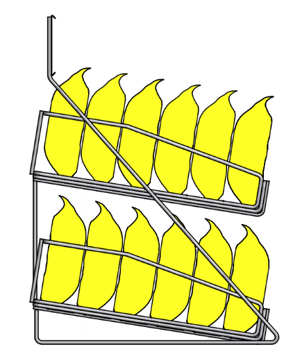

These baskets run the gamut from harvesting raw shellfish, to deep-frying large turkey legs, to holding finished packaged goods in retail displays. That last use is one that may surprise you. Why would a company want to use a precision-engineered retail display wire basket that was made in the USA instead of a cheaper foreign-made basket?

There are a few reasons:

1: Aesthetic Appeal

One of the key reasons food manufacturers approach Marlin Steel to create a wire basket for their products’ retail display units is to get something that is aesthetically appealing. In a store, it isn’t enough for the product packaging itself to look good, the whole display has to be appealing to shoppers to catch their eye and create a positive impression.

One of the key reasons food manufacturers approach Marlin Steel to create a wire basket for their products’ retail display units is to get something that is aesthetically appealing. In a store, it isn’t enough for the product packaging itself to look good, the whole display has to be appealing to shoppers to catch their eye and create a positive impression.

Marlin’s American-made baskets leverage not only great automation technologies (such as wire bending robots, automated sanding machines, and medium frequency direct current [MFDC] welders that minimize weld spatter/discoloration) to achieve consistently attractive results, but the expertise of a team of degreed mechanical engineers to create an ideal custom shelf, rack, or basket for retail display.

This makes for a consistent final product that has neatly-arranged wires of consistent length and shape from one basket to the next, a smooth finish that doesn’t detract from the appearance of your product, and allows products to be placed in an ideal layout that emphasizes its packaging design.

2: Customer Safety

One of the things about some custom wire baskets made by foreign companies that rely on underpaid manual labor to decrease costs is that the surface finish is often not a major concern for them. If manual cutting, welding, and finishing processes leave sharp edges on wires or burrs near weld sites, then that’s just how the basket is.

These sharp edges, however, can create a safety hazard at the store site. Customers (as well as store employees) can get injured on the sharp edges of an improperly-finished basket. This creates unnecessary injury risks and potential lawsuit liabilities for the store—and, good luck recovering those legal expenses from a foreign manufacturer governed by a different court system.

Custom retail display baskets made in the USA are held to a higher standard—and, their manufacturers are part of the same legal system as you, so at least you have a fair expectation of recovering your expenses if the manufacturer does mess up on the quality of the basket and it proves unsafe.

As mentioned earlier, Marlin Steel uses a variety of automated manufacturing tools to minimize the occurrence of sharp edges or burrs that could cause injury. Then the Marlin production team uses parts grinding equipment (or electropolishing) to eliminate any surface defects that do occur. This creates a smooth, flat, safe contact surface that minimizes the risk of injury.

3: Speed of Delivery

With a foreign-made basket, there are numerous built-in delays that could see you waiting a long time to receive your retail display wire baskets.

With a foreign-made basket, there are numerous built-in delays that could see you waiting a long time to receive your retail display wire baskets.

For example, your basket shipment has to sit in customs for inspection in the exporter’s country. This could be a delay ranging anywhere from a few hours (if all the red tape has been expedited) to a few days or weeks. Then, the shipment has to wait for available cargo space on a vessel traveling from the country of origin to the USA. This wait could be weeks or months depending on the size of the shipment—trying to schedule a cargo vessel while the shipment is in customs isn’t always practical since you can’t always rely on it to clear customs in time for an earlier shipment.

After spending weeks at sea, the shipment will have to go through the U.S.-side customs process—everything from verifying the right to make entry, to the examination of goods and entry documents, to the packing of the goods with other products for efficient shipping. With luck, the U.S. customs process will only take a few minutes (or hours) before your shipment cleared and ready to ship. All told, you could easily expect to wait a full fiscal quarter (or more) before you get your retail wire display basket.

With a “Made in the USA” display basket, you can skip the customs and cargo vessel wait times. Instead, as soon as the retail display unit is ready, it is put directly into our nation’s robust shipping infrastructure. This helps to ensure that you receive your display materials in time to use them to compliment your products rather than having to wait for months.

In the end, when you order an American-made custom retail display basket rather than a cheap overseas basket, you get superior quality and safety on a tighter schedule.

Do you need a custom retail display basket that helps you show off your products in a storefront? Contact the Marlin Steel team today for more information about your custom basket options.

.gif)