Gun manufacturers are currently facing surges in demand unseen in decades. To keep up with booming firearms sales, gun manufacturing companies must increase their production and efficiency while reducing scrap materials. Additionally, product quality must also be prioritized in the gun manufacturing process.

Gun manufacturers are currently facing surges in demand unseen in decades. To keep up with booming firearms sales, gun manufacturing companies must increase their production and efficiency while reducing scrap materials. Additionally, product quality must also be prioritized in the gun manufacturing process.

There can be no flaws during the gun manufacturing process or else the integrity of the firearms will be compromised. While it’s important for firearms manufacturers to keep up with the current demand, precision must also be prioritized to prevent any product flaws. With Marlin Steel’s metal racks and baskets, gun manufacturers can streamline the gun manufacturing process while ensuring product quality.

Why Are Gun Manufacturing Companies Facing a Surge in Demand?

The COVID-19 pandemic not only resulted in shortages of hand sanitizer and toilet paper, but also a product that may have been unexpected to some: firearms and ammunition.

According to the FBI, nearly 4 million background checks for gun ownership were conducted in June 2020 alone - the most since the system was installed in November 1998. In fact, almost 20 million checks have been conducted halfway through 2020 - which amounts more than all of 2012 and each of the years previous to it. And, it’s not just guns that are selling out quickly - ballistic body armor, medical kits, military field rations, flashlights, knives, and other survival gear are also in an unprecedented demand.

Why the surge? The demand can be traced to the current political and economic climate. The COVID-19 crisis, economic chaos, and widespread demonstrations have led to unease among citizens - and a surge in gun ownership. Many of these gun buyers are first-time owners that are assuaging their fears in the breakdown of public order with a firearm and survival gear.

With ammunition and firearms flying off the shelves, gun manufacturers have extra pressure to keep up with the demand while not compromising quality.

How Can Marlin Steel's Wire Baskets Facilitate A Quicker Gun Manufacturing Process?

Luckily for gun manufacturing companies, Marlin Steel’s wire baskets can facilitate a more efficient gun manufacturing process so firearms can be manufactured precisely while being shipped out the door quicker than ever before.

Better Precision

Precision is of the utmost importance for gun manufacturers. Marlin Steel can help gun manufacturers maintain the tightest quality with metal baskets. Due to specialized coats picked by Marlin’s in-house chemical engineers, metal baskets never scratch delicate parts so you don’t have to worry about any damage to gun components during the manufacturing process. This reduces scrap, extra production time, and costs.

Additionally, wire baskets are engineered with finite element analysis, a simulation tool that is used to analyze and test components and systems’ strengths and behavior under environmental conditions. Along with the state-of-the-art AutoCAD software, the finite element analysis tools enable wire baskets to be manufactured as high quality as possible so they exhibit no weaknesses during the gun manufacturing process.

Faster Shipping

How firearms components will be moved during the gun manufacturing process will affect the efficiency of your operations. A more efficient process means less time during the gun component manufacturing and the faster products can be delivered. Wire baskets can be outfitted with extra parts to be perfectly optimized for your gun manufacturing process. Metal baskets can be designed to be moved by hand or for conveyor belts to increase ease of handling and production speed, so your products can reach shelves quicker than ever before.

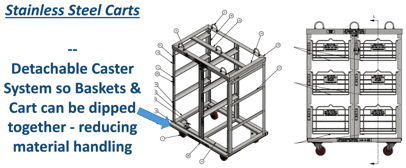

Additionally, Marlin’s stainless steel carts can increase transit speed in between operations. By placing metal baskets on carts, transportation speed is increased without causing additional employee strain due to material handling.

When the process is complete, Marlin Steel’s products can reach shelves faster than any foreign products. One of the many benefits of being domestically produced is the elimination of products needing to ship through international waters and sit through customs processing. You can receive Marlin’s metal baskets within days of your order, so you can start keeping up with the demand as soon as possible.

Customizable

Marlin’s wire baskets can be customized to fit any of your unique gun manufacturing  process needs. Since 20% of Marlin’s employees are degreed engineers, you can trust that metal racks and baskets have been expertly designed to improve manufacturing flow and eliminate any downtime.

process needs. Since 20% of Marlin’s employees are degreed engineers, you can trust that metal racks and baskets have been expertly designed to improve manufacturing flow and eliminate any downtime.

For example, metal baskets can be customized with lids for added protection and stacking, or outfitted with handles for easier transportation during the gun manufacturing processes. Whatever your unique needs may be, Marlin Steel’s engineering team can design metal baskets to fit your requirements.

Are you ready to keep up with the surge in demand? Reach out to the team at Marlin Steel for advice on picking out the right stainless steel metal baskets for your needs so you can have the most efficient gun manufacturing process available.

.gif)