Choosing the right steel basket for gun manufacturing is vitally important for firearms  manufacturers since they can help during the manufacturing process in multiple ways. However, wire baskets used for gun manufacturing need to be of high quality to ensure the utmost precision since any flaws are unacceptable in the industry. Besides, gun component integrity ensures the quality of the firearm and the safety of the user.

manufacturers since they can help during the manufacturing process in multiple ways. However, wire baskets used for gun manufacturing need to be of high quality to ensure the utmost precision since any flaws are unacceptable in the industry. Besides, gun component integrity ensures the quality of the firearm and the safety of the user.

Wire baskets made with stainless steel offer numerous benefits, ranging from enabling productive manufacturing operations, to reducing scrap and maintaining product quality. Here are ten more ways where Marlin Steel’s metal baskets can increase operational flow and efficiency during the gun manufacturing process.

10 Benefits of Using Marlin Steel Baskets for Gun Manufacturing

Here are just a few of the examples of why Marlin Steel baskets for gun manufacturing can optimize efficiency and reduce costs due to scrap.

1. Optimize Gun Manufacturing Processes

Marlin’s wire baskets are built to optimize curing, dipping, or bluing processes so that the parts inside can be cured as much as possible. Since 20% of Marlin’s employees are degreed engineers that focus on manufacturing designs that improve flow, you can trust that these baskets have been expertly designed to optimize these processes.

2. Engineered for Precision

Marlin’s basket for gun manufacturing is engineered for easy transport so parts do not roll out or get lost. Baskets are designed to be gripped precisely so there’s less risk of damage in transit across the facility.

3. Kitting for Efficiency

Wire baskets enable kitting parts so, at the end of the line, all the parts of the complete gun can be manufactured in one shot. Kitting not only reduces the total manufacturing time, but also makes it easier for employees to realize if key components are missing before it’s too late.

4. Reduce Material Handling Strain

With hoist handles, Marlin’s steel baskets reduce material handling strain on employees by providing less strain on backs. Hoist handles also allow for smoother transportation by minimizing the chances of small gun components dropping and getting lost throughout the manufacturing process.

5. Reduce Scrap

You never have to worry about Marlin Steel wire baskets damaging gun parts. Due to specialized coats picked by Marlin’s in-house chemical engineers, metal baskets never scratch delicate parts. This ensures minimal scrap, saving your gun manufacturing company from extra production time and costs.

6. Accurate Labeling

Each basket is individually labeled, so if a lot is made incorrectly, the entire load of the product does not need to be destroyed, inspected, or reworked. Instead, a surgical analysis of only the baskets that hold the suspect parts needs to be checked. This helps both increase productivity and reduce expense costs since the damaged parts can be quickly identified and reworked rather than the entire unit.

7. Customize with Lids

Wire baskets can be customized with lids for added protection and for optimal stacking. With lids, delicate gun parts are protected within the basket and any risk of parts falling out during the gun manufacturing process is removed. They can also be stacked on top of one another, which is ideal for gun manufacturers looking for storage solutions with their wire baskets.

8. Precise Welding

Marlin’s wire baskets are manufactured with the utmost precision. Each basket weld joint is  welded in a uniform fashion by advanced robotics to ensure maximum accuracy and strength.

welded in a uniform fashion by advanced robotics to ensure maximum accuracy and strength.

9. Finite Element Analysis for Accuracy

Each Marlin Steel basket is manufactured with finite element analysis, a simulation tool that is used to analyze and test components and systems’ strengths and behavior under environmental conditions, and Marlin’s state-of-the-art AutoCAD software to ensure gun manufacturers are receiving the highest quality steel product. The AutoCAD and finite element analysis tools make sure the wire baskets are built to withstand weight capacity and environmental conditions before they’re shipped out.

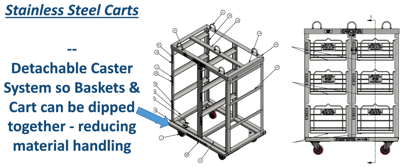

10. Customize With Carts for Speed

Marlin’s stainless steel carts are designed to work with steel baskets for gun manufacturing to increase transit speed in between operations. Carts not only increase transportation speed, but also reduce employee back strain due to material handling.

Marlin’s stainless steel carts are designed to work with steel baskets for gun manufacturing to increase transit speed in between operations. Carts not only increase transportation speed, but also reduce employee back strain due to material handling.

Experience More Efficient Gun Manufacturing with Marlin's Steel Baskets!

Are you convinced yet that your gun manufacturing processes can be expedited by Marlin Steel wire baskets?

Are you convinced yet that your gun manufacturing processes can be expedited by Marlin Steel wire baskets?

If you are ready for more efficient gun manufacturing with Marlin Steel wire baskets, or if you need advice for picking the right stainless steel basket for your needs, reach out to the team at Marlin Steel. Marlin’s engineering team has years of experience in crafting custom stainless steel wire forms and can design one customized with your specific requirements in mind to meet your gun manufacturing needs.

.gif)