For any parts or materials cleaning process, you generally need some kind of container or device to hold parts in place as the cleaning cycle commences. With the wide range of toxic and/or corrosive chemicals used in modern manufacturing processes, doing things by hand just isn’t practical or safe for many parts finishing processes. This is as true for ultra-delicate circuit boards as it is for solid metal parts.

Washing delicate parts such as circuit boards requires specially-made custom containers to hold the boards in place securely so that they don’t rattle around and get damaged. However, parts still need to be exposed enough for the washing process to do a thorough job. This is where wire mesh baskets come into play.

Over the years, Marlin Steel has developed numerous parts washing baskets for circuit boards of many different shapes and sizes. Examples include:

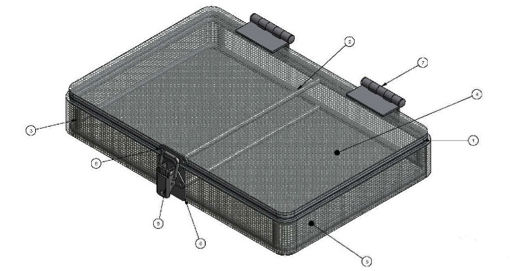

UV-01751001

Crafted to hold large circuit boards, this parts washing basket was designed with a lid to keep the circuit board inside from falling out during wash processes that involve rotating the basket.

Crafted to hold large circuit boards, this parts washing basket was designed with a lid to keep the circuit board inside from falling out during wash processes that involve rotating the basket.

Like many other parts washing basket, grade 304 stainless steel was used for the frame, mesh, hinges, and all of the other metal parts of the basket for corrosion resistance. For the wash process that this basket was originally designed for, 304 stainless provided the best combination of useful life, tensile strength, and cost for the customer.

Large, sturdy hinges and a latch make the basket easy to open and close, even when being handled with gloves. The mesh is fine at a thickness of 0.063 inches and has enough open space between each wire to allow liquids and high-pressure sprays to pass through easily.

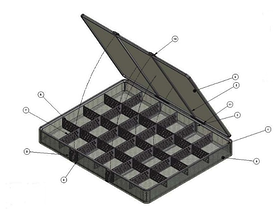

DYN-02004001

This basket was designed to be able to hold either one large circuit board, or many smaller pieces of circuitry at once.

This basket was designed to be able to hold either one large circuit board, or many smaller pieces of circuitry at once.

The dividers in this basket are removable, not permanently welded to the frame. This allows the dividers to be removed and replaced easily in order to accommodate different parts, making the basket useful for multiple product lines.

In addition to being made of grade 304 stainless steel, this particular basket was given a black PVC finish. PVC finishes, when applied in a thicker coat, are great for minimizing the chances of delicate parts being damaged from contact with the metal basket.

ROC-01967003

Designed for use with bulkier loads of circuit boards, this basket was designed with a thicker wire frame and a lid that clasps closed without the need for a separate latch mechanism. The wires of the mesh are thick to support the weight of larger circuit boards. The bottom of this lidded basket features reinforced support bars to provide further support.

Designing the Right Basket for the Job

Beyond being steel wire mesh baskets with lids, each of the above baskets has something else in common: they were each custom-engineered for a specific purpose.

With the creation of any custom wire basket for a washing process, it is important to consider multiple factors, including:

- The object to be cleaned: its size, weight, and shape.

- The wash process itself: cleaning temperatures, chemicals used, and mechanical processes used.

- Method of manipulating basket in-between wash processes.

- Useful life: having to replace baskets too frequently is not cost effective. Designing baskets for longer useful life makes for a better investment.

Marlin Steel’s degreed engineers have years of experience in handling the design needs of custom wire forms for numerous applications, including the washing of delicate circuitry and other electronic components. Using that experience, Marlin’s engineering team can help you design the perfect wire basket to meet the demands of your parts washing process.

Building the Perfect Parts Washing Basket

To ensure consistent results, Marlin Steel uses automated manufacturing equipment such as wire bending robots, automated welders (including a new medium-frequency direct current welder), CNC press brakes, and laser cutters. These automated devices can perform tasks rapidly and consistently. Unlike manual laborers, these machines don’t tire out, and are capable of repeating tasks with micrometer-accurate precision so that every bend, cut, and weld is consistent.

Also, these machines greatly enhance safety on the manufacturing floor. At the time of this writing, the Marlin Steel production facility has gone more than 2,000 days without a serious safety incident. Because of this dedication to safety, Marlin’s production lines are able to continue at full speed every day.

Check out more wire baskets with lids today on the newly-revamped Marlin Steel website!

.gif)