Misc

Media

Media

INITIATIVE FOR A COMPETITIVE INNER CITY UNVEILS ANNUAL LIST OF THE NATION’S 100 FASTEST-GROWING COMPANIES IN UNDER-RESOURCED COMMUNITIES

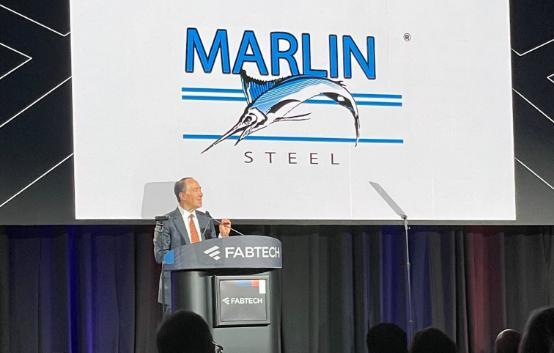

Marlin Steel wins IC100 Award

I'm passionate about USA manufacturing. I believe there's going to be an American manufacturing renaissance. I think we're in the middle of it right now. We're at a wonderful inflection point and today that we'll be talking about.

I wear two hats. Not only do I own a skilled fabricator in Baltimore, Maryland, I really make things like you guys do. I also have a hat. Uh I'm the chairman of small mediumsiz manufacturers for the National Association of Manufacturers. It's given me an amazing exposure to what's going on in Washington and I'm going to share some of that with you.

I'll also be talking later on about some of the tools and techniques that we use at Marlin to improve employee engagement to get your employees thrilled and fired up and motivated and dedicated to work in your facility. We'll also talk about reassuring. That's a very important topic. I had the pleasure of not only uh having some nice conversations with several of your co uh co-members, a number of them told me about jobs they're bringing back from overseas here in San Antonio. So, it's not just Marlin Baltimore feeling it. It's also some of the some of your fellow uh people in this room, which is thrilling. So, the bottom line is we're very optimistic about the future. and I was going to describe some of the things that are cooking in Washington.

So, the bottom line about manufacturing is it means American jobs. It's the most uh critical element and why I'm so enthusiastic about manufacturing. We pull people up out of poverty. you bring them into the middle class. It's like that when you're flipping hamburgers. It's not like you're a barista serving coffee. Manufacturing is unique in that it launches you to a level that's uh that that Americans thrive and prosper at.

Specifically, the average American factory worker is paid $80,000 a year. That's a stunning amount of dollars. That's the average. If the company is a uh is an exporter on average it's $9,000 a year average. Obviously some are higher and some are lower. But this these are amazing jobs that Washington has to copy that our nation has to appreciate. This is a middle class you can really send your kids to college or you can have a nice vacation. It's it's the way the rungs the ladder connects up.

We're at a very important point, I believe, in manufacturing. It's similar to the 60s when John F. Kennedy said, "We cannot afford to wait and see what happens. While the tide of events sweeps over and beyond us, we must use this time as a tool, not as a couch." JFK said that to the National Association of Manufacturers in 1961. It's it's as if he could have said it today to us.

I had the privilege of meeting President Trump in March and we spoke face to face. Uh this is me uh introducing myself with a number of other small and mediumsiz manufacturers and we talked about some of the issues that we're grappling with things that we need to do to improve the policies so that we could all thrive and we could all do better for our economy.

Why were why were we there? Because manufacturers are unbelievably optimistic. Unbelievably optimistic. We do a national association of manufacturers does a quarterly survey where we ask manufacturers, hey, what do you think is going to be the prognosis for the future optimistic pessimistic block caucus for this has been going on for over 20 years. The survey the results went from under 57% to 93% in the March. right after the election. 93%. That's like a North Korean poll election, right? 93%. Right? By the way, the two polls since then, it's it's hovered over uh 90% average over the three uh periods.

It's not just manufacturers that are enthusiastic. You can see the uh conference board consumer confidence, University of Michigan consumer confidence, NFIB, small business optimism. Everybody's enthusiasm. It's not just manufacturers. This is one of the few times people will say it was actually a positive tweet. President tweeted us out. Okay, it was a good thing. That's me right there in the Oval Office and this is us meeting with him.

So when we were there, we talked about the issues. Before that, we met with Vice President Pence and we talked about the topics that are important to the manufacturers. We spent over an hour with Vice President Pence on more than one occasion. This is the second occasion we've done with Vice President Pence. That's a signal that the president and the vice president are reaching out to National Association of Manufacturers, embracing them, want to hear what's going on. Just as an FYI, every single president who's met with the National Association of Manufacturers, Executive Board since FDR, everyone, FDR, Truman, Kennedy, Brady, all of them, he was only one for 8 years, he didn't meet us. Okay? It's such a contrast that in the last couple months, we met with him many, many times.

So, President Trump said to us in that oval office, we're going to bring that manufacturing to the United States. Vice President Pence said, "It's unacceptable what's been going on with the economy. We have been going at an anemic pace. It's unacceptable. We've been averaging growing 2% a year GDP in the United States. We're going to move this fashion 4 to 5%. Mind you, that's doable." Reagan was at 7%.

Thank you. I could have more passionate about bottom line is Vice President Pence said we're bringing us back to four to 5%. Why is why is this so viable and achievable? Remember Ronald Reagan got us a quarter of 7.3%. pretty dual 45% getting it done. We're going to see it happen.

I created this little acropolis based on what Trump pushed jobs, jobs, jobs. I'm bringing jobs back to America. I believe these are the seven pillars to how Trump and this new administration is going to pull this off. These are the seven explicit reasons why manufacturers are optimistic. Why are we 93% these seven reasons? Let's but let's scroll back. Vice President Pence said, "President Trump is going to do the same thing that worked in Indiana, which where by the way, Vice President Pence was the governor. He said, "We're a right to work state. We're a low tax state. We're a low regulation state." Those things worked so well for us. Indiana pushed Indiana's number one state as a percentage of jobs. Uh that's manufacturing employees. Our techn worked. Those are that was the strategy. We're going to use that in America. By the way, these are similar strategies that are being used in Texas and that it's working really well in Texas as well. This is a good strategy.

When we talked to Pence, he stressed how humbled he was. He was choked up. He was literally choked up when he was talking with us. How humbling it was to have this position. How important it was to bring back the American dream to America. Bottom line is Pence and Trump said, "We're going to make America more competitive. We're going to be the reason why people are going to close factories overseas and move it to the best place in the world to build a factory in America.

A lot of people in Washington when we have meetings with them, this is what they think of when they think of manufacturing. They think of this 1950s picture from Pittsburgh with big big smoke stacks belching out smoke, not treating their employees well. That's how most Washington politicians think of us. They're wrong. They don't know what's going on with modern manufacturing. And another critical thing about um most politicians in Washington, they don't realize that most of us are small and mediumsiz over 227,000 manufacturers. 229,000 manufacturers in America. Over 227,000 of us are peanuts. They're tiny. They're under 500 employees. Most American factories have between 10 and 15 employees.

So let's talk about the the sropolis that's created to improve the job outlook. Number one is US USA energy. I'm in Texas. I don't have to explain to you how important energy is. Okay, you guys get it. Having low feed stock, low cost energy, whether it be coal, whether it be shale, wherever it's coming from, is a good thing because if our prices are cheaper, we're going to be more competitive against Korea whose fuel prices are three times higher than us, cheaper than China, etc. Unleashing American energy is going to do wonders for our economy because you need people on the Dakota pipeline welding. You need people on Keystone uh uh pulling pipe driving the pipe to the uh to the point of contact. All kinds of jobs are created. Bottom line is this is critical that domestic manu for domestic manufacturing unleashing our energy.

By the way, this right here is James Branch. He's one of our factory employees. The New York Times did a story about him a year ago, October. Interesting fellow. Like many people in Baltimore City, he didn't have a lot of opportunities. And this is what uh New York Times focused in on. Matter of fact, he had poor education. So what did he do? He started dealing drugs. He fast life. He got into big trouble. He served his time. He got out. He said, "I'm never doing that again." started working at Popeye's minimum wage. Pivoted over to manufacturing. Fast forward, works at Marlin, runs several $40 million machines as a wire forming machine. He runs his machine on our behalf. He's made so much money and he's now part of the middle class. He sent his daughter through college. She graduates stories. If you if you Google James Branch in the New York Times, Marlon Steel, you'll read their article about it.

Number two is infrastructure. Infrastructure is critical to manufacturers. We need good roads. We need good ports. We need good airports. We need good sewer systems. Our systems are decrepit in their own. If you look, we haven't been investing properly. In the 70s, we were almost 3.8%. You can see how we're letting our assets deplete. We're not doing proper maintenance. You guys run factories. You know what happens if you don't maintain your equipment? It breaks, right? Well, that's what's happened with our roads and our ports. It's unacceptable. If you've ever flown to Shanghai or Beijing, they have gorgeous airports, right? You compare that in contrast to LaGuardia or JFK, it's embarrassing. You know, we're like Bangladesh when it comes to roads in Baltimore City. It's because we're not investing properly. President Trump's talked about investing over trillion trillion dollars into our infrastructure. It's needed. The American Society of Civil Engineers great this is a D+ D plus America the greatest country in the world should not be a D+ on infrastructure. President Trump who's a builder I believe is going to improve this.

Next is tax reform. It's a hot topic. We had a good day today in Washington. It was a critical day. A very important vote happened. It's not all done. We got a ways to go, but tax reform is going to be really good for American manufacturers. And part of the reason why we're optimistic, JFK had a great line. He cut taxes in America. And the way he explained it was, it's a paradoxical truth that taxes are too high today. Sound familiar? And tax revenues are too low. And the soundest way to raise the revenue in the long run is to cut the rates down. Well, that's what President Trump is going to do. He's go he's using the JFK playbook, also Ronald Reagan playbook. And when they cut taxes, revenues went up. Okay? The economy flourished. That's going to happen again. Buckle your seat belts. I'm optimistic. I think you should be optimistic. It's going to be good when this starts rocking and rolling. The last time we updated our tax system was when Ron Reagan was in office in 1986. That was him giving the pitch. That's crazy.

When Donald Trump announced that he was going to be pursuing this, he did this in front of the National Association of Manufacturers. When he got out of the window, I had the privilege of meeting him and shaking his hand. And I told him because he's doing this, Marlin, my company, is going to be investing $1.2 million before the end of the year in new investments because we're going to be uh exploiting this excitement and we're going to take advantage of it. I hope you can consider it as well. And that's that's what I told him. He said to me, "It's going to help you because rather than you writing things off over 30 years, you'll be able to write things off this year."

So, let's talk about Donald Trump's plan. It's going to reduce uh how many brackets we have from 7 to three. You know who hates that kind of stuff? H&R Block. Okay, it's good. Simplification is good. People that are paying at a 10% rate, they're going to pay at a 0% rate. He's going to reduce the corporate tax rate, that's the big guys, from 35% to a lower number, hopefully 15%. That means guys like GE and Caterpillar and Ford and people that I know we sell to Merc and Bartis, they're going to have a lower tax rate. Hopefully, we're going to be able to win more jobs when they compete against Kamasu in Japan or they'll be able to compete better against Seammens, etc. It's going to eliminate the death tax. It's very important for people in this room that own a business, uh, a small business. You don't want the government to own half, uh, of the tape of your hard work, of your entire life hard work. And, uh, other benefits is big simplification. 90% of Americans are going to be paying with a postcard, not with uh, accountants getting rich off of our fees. In addition, LLC's and subasset corporations, 70% of factories are organized as an LLC or a subscorporation. 70% of us pay in this way. Our rates can go from 39 something% down to 25%. It's a tremendous benefit for all of us.

We talk about instant expensing. They're talking about instant expensing if you buy a building, okay? Or if you buy any kind of robot or automation, this is going to give your employees amazing tools. So, they're going to be more competitive against Mexico. they're going to be more competitive against China. So, you it's more viable to build here in America. This is Max and she does all of our fixtures, the molds. When we make a basket, she makes the uh the unit that holds all of our parts as they go through the various robots. Bottom line is this plan, according to some economists, will increase 6 12 million jobs into the USA. 6 and 12 million. Bottom line, tax reform is critical to American manufacturing. We desperately need it.

The Chamber of Commerce has put this together where it's a stepbystep by date what has to happen when and we're chugging through. This is a little outdated because this is from last week as I was preparing for this meeting. Um we we're knocking off these things. We're moving it all forward. Hopefully there is a sign before Christmas. What a blessing be for all of us.

Bottom line is you can see right now this is where our tax rate is for our companies like Caterpillar and General Electric. This is the worldwide average. This is why senior wins jobs. This is why Kamasu beats Capital because they can charge this kind of rate and we're charging this kind of competitive. We're we're getting our own getting our clocks cleaned with this current system. This is Ken who makes our samples and our fixtures. if you're doing a job for gold.

Next is repatriation. There's over $3 trillion, some say four, some say $5 trillion locked up overseas. Why? Because what happens is big companies like Facebook and Google and GE. What will happen is they'll make money overseas in a factory overseas and they can't bring it back because they get taxed only in the same plants. They'll get taxed again when they bring it back into America. That double taxation is a big no. Nobody wants to pay their taxes twice. So what do they do? They keep it overseas. It's been sitting over there bank accounts, French bank accounts, Japanese bank accounts. It's earning negligible interest rates. If it all comes rushing home, it's going to be the biggest sugar rush for our economy. It's again, it's unclear whether it'll be $2 million of cash rushing home or four trillion. It's going to be delicious because people are going to come back. They're going to invest in factories. They're going to buy robots. They're going to buy automation. They're going to hire people. learn a new marketing campaign. Some of it will be dividends that will be good for the stock market. Some will be share buybacks that will be good for the stock market and engineers and bottom line is it's going to be such a blessing for our economy and it be a nice shot in the arm to really get things rolling.

Trade, the president has talked repeatedly about trade and how he's going to take it differently than prior administrations. One of the first things he did was get out of TPP, Trans-Pacific Partnership, where he had 14 countries doing a deal. New Zealand, Vietnam, Peru, Japan, America. He had 14 countries all in this one deal. He got out of it.

For years and years, I've been very supportive. I've been very supportive of trade deals like TPP, like NAFTA, etc. The president is is vigorously against it. We talked with Vice President Pence about why why would you get out of TPP? It sounds like such a deal. And Vice President Pence explained it to me this way. It was a very compelling answer. He said when we're negotiating with 14 other countries, right, our heft, our power, our our frost, right, is dimminimized is minimized because we're we're we're a smaller subset of the of the 1400 countries. We instead want to cut a lot of deals, but we want to do bilateral deals, oneonone deals. Why? Because we're sitting down in Peru, we're an 800 lb gorilla. they got to cut a deal with us. We're we're huge. But if we're part of 14, we minimize our our stature and because of that, we can't command us being a deal. But if we're oneonone versus Vietnam, oneonone versus Japan, we have more heft. We'll we'll be able to push around uh the other country in a in a fashion to protect the American manufacturing war. That was their point of view.

Let's see how this all plays out. Uh it's critical that we remember though that trade is very good for America and very good for factories. You can see here the blue line is manufacturing output. Here's NAFTA. Here's WTO, the Korean Free Trade Agreement. You can see manufacturing output consistently goes up and manufactured goods are being exported consistently goes up. NAFTA, the the Korean Free Trade Agreement, these guys had the worst press agent in the world. Okay, the the beating that these uh trade deals had is uh merciless. Okay, they have partially propelled a lot of success. Now, the DA deal is old. It's 23 years old. There's supports on it. It was before I were created, but bottom line is uh trade is good for our nation.

And you can see almost 50% of American output, American factory output is exported. And when my guys watch us make baskets that ship to Poria in Illinois from Caterpillar, they think they're shipping to a domestic product, right? That's not reality because what's happening is when Caterpillar ships, more than 50% of what Caterpillar ships goes overseas from that plant. So really, we're we're deeply inconsistenc. We need a thriving export market. all these things and just so you know it's not just factories it's also uh farming one in three acres in America is exported

Next is regulations. regulations another reason why American manufacturers are so optimistic. He specifically vice president specifically talked about the carrier deal that uh where carrier was thinking about leaving but President Trump uh pressed them to stay in America. Pence told us the backstory. According to Pence, what happened was they were the last company carrier was the last company in their industry that was still making domestic. Everyone else, all their other uh competitors had already fled America. They were already overseas. They were the last one holding out. And in the last two years of the Obama administration, there are over 50 new regulations imposed on them. and they couldn't take and that was the straw that broke the cables back. So, they gave up and they said, "We're out of here." Trump called them up and said, "I'm going to get rid of every one of those two so you will stay." And they did. And that's what Pence attributes uh them coming back.

Regulations have killed companies. People don't see how insidious it is and how and how uh challenging it is for American backers. Churchill had a great line. If you have 10,000 regulations, you destroy all respect for the law. Here's the problem with American manufacturers. We have over 297,000 regulations today. It's out of control. Everybody wants clean water. Everybody wants clean air. Everybody wants worker rights. You can't be mean to your workers. You have to You can't spoil the environment. That's a given, right? But you can get away with doing all those things without 297,000. Obviously, some of that is ridiculous and over the top.

President Trump explicitly asked us when I was in that room with him to say, "Listen, don't give me platitudes about regulations." He said specifically, "Give me rules that are job killers for you. Give me a list." National Association Manufacturers compiled a list and we submitted it and they're hammering away on that list. If you in this room have an idea, a job killing regulation, I implore you, he insisted that we give him more things to to work over. Anything that's slowing you down from hiring a person, please email me. I'll have my email address at the end. Please email me that job killer regulation and I'll get it in the hands of the right people and hopefully no guarantees we can get this thing knocked down. Okay. fire the bureaucrats who sit around all day and the NOS's really crap up. That's how they justify their get them out. You haven't been working for years. They let them go back and decide I don't want to do that. say they're they're looking for explicit regulations very you know you know which code which agency I was having uh drinks in in the beginning uh at the cocktail and some of the people that I met told me about some of the challenges they had and the finds they had that were over over the top over what ridiculous finds okay and and things that made just absurd right so I I handed my card out to a couple people if you think one of these tool that's impacting your business, slowing you down from hiring something, let me know. I'll get into the right hands. No guarantees. Hope you can pull some help.

This is Eddie. He works in our wire fabrication. This is Chris. He's one of our mechanical engineers. The bottom line is manufacturers need regulatory so we can grow our economy. And 87% of American factory owners say if we had less regulations, we would hire more people. We'd invest more in our economy. And it really is an outsized pain to small guys. If you look here, the average American factory that's small, under 50 employees, is paying $34,000 per year per employee in regulatory burden. That's unacceptable. Now, again, we want clean air. Again, we want clean water. We wanted to protect our workers. These are given, of course. But can we do it with maybe only $17,000 of pain? Can you imagine how many jobs we've created in our nation? If we can get that to be a more tame number, I did want to stress one thing. The president promised on the campaign that he was going to get rid of two regulations for every new one that they imposed in Washington. There you go. He's done better than he promised. specifically he's so far cutting 16 to stick to that's the ratio right now 10 months in it's early he's hopefully going to do better 16 to1 this is again part of the reason why Americans are so optimistic and obviously as you guys know the Keystone pipeline was started the Takakota pipeline was started and we we're he's ended the war on coal all of these things are happening and this confluence of events is going to really create a very positive ascent for American manufacturing And again, a cornerstone to why I believe the American manufacturing Renaissance is going to thrive.

There's a couple other subtle things that's a win for factories that people don't talk about. The president promised that he was going to have Scaliaike justices um deciding adjudicating our cases. Well, Gorsuch is only one. He falls into that bucket. So, he's done a great job. And some people think he he may get three more Supreme Court justices before the end of his tenure, which would be stunning. He's already nominated 60 judges and there's 160 and right now they're soon to be filled. One thing that's important about these judges is how they interpret the laws and how they um go about. This is going to have a big impact not only regulations but in a way the regulations how the regulations are interpreted and remember these judges might be sitting in those benches for 30 years. So this is not just a 4-year window of goodness for 30 years we would have rational people interpreting the laws in a way that's um in a way that's uh productive from

let's talk about healthcare reform. not too pleased with how that's been going. Uh this is Nathan. He runs one of our wire forming robots, actually five of them. Uh and he actually on manufacturing day, the president made us an announcement and a proclamation for manufacturing day and Nathan was standing behind him in the Oval Office. And when the president signed the proclamation, he gave the pen to Nathan. He's cherishing it.

Um healthcare bottom line, the house voted the right way. That was a good thing. Unfortunately, the Senate failed uh very miserably. Uh we met with Senator McConnell who's uh the fellow that's in charge of the Senate and he said, "You guys know the 8020 rule?" Chuckle, because you know, if you're a manufacturer, you you know the 8020 rule. He's like, "I spend 80% of my time on four senators. I have four senators that I have to spend 80% of my time with." Okay? We came so close to the Senate. Didn't happen. It's devastating.

However, hopefully it will get better because they'll reook at it again in the future. No guarantees. In the interim, he legislate it through administrative through the pen. He said, "We're allowed to start buying from other states." So, right now, I'm from Maryland and we have basically a cartel. you know, I just have a handful of companies and we used to have a lot of companies, but now I just have a very small group of companies that we can buy from. I can't wait to have an opportunity to buy from Texas or can't wait for, you know, Virginia or South Dakota, whoever has a better deal, right? I have the same health insurance plan as my employees do. My book, my three boys, my three boys have the same plans as Nathan's kids, right? So, it really matters to me. And I I hope by having lots of competition, we'll all do better. And at least that's a a partial win. Hopefully they'll come back and we'll get a good vote.

If you believe like I do that these policies that we just talked about this acropolis is so critical, I ask you please text right now. It's okay to get your cell phone out. How often you hear a speaker say that? Please get your text your phone your your cell phone app and text the word friends to this number right here. 52886 and you'll be put on a list of people and they'll tip you off when there's a new some new legislation coming out where we need you. We need your support so that you can email or text or have your more importantly, much more importantly, have your employees call critical Congress people or senators that are not voting the right way that need a little nudge for reality check because they need to hear from our side how to do it, how to vote, and it will tip you off via text. Hey, this is an important piece of uh legislation coming up. Please tip off your cover. So again, it's 52886. Text friends and we'll add you to the list. By the way, I'm going to give Ry um a copy of this and if anybody wants to look at this later or share with somebody, you'll be able to share it with them afterwards and you can get it then.

So let's talk about Resort. Ray said we is an important topic in this area. Let me tell you a little anecdote about us. Our best number one client in 2008 came to us in 2008 because they were having quality problems out of Ireland where they were getting all their things made. They were making it in Ireland and then importing it to Nebraska and that was going on for many years. Quality was atrocious. They were having fits. They pivoted to us as our biggest order ever. It's consistently been our biggest order ever. It's telecommunications wire forms and we were shipping to Nebraska and then uh got a bad phone call. They were moving the plant from Mexico, you know, all of a sudden, you know, we were like biting our nails. Scary, scary stuff, right? And turns out didn't work out so bad for us, bad for the people from Nebraska, but we kept one and every day now we ship to Mexico and they make the parts in Mexico. And to my surprise, the Mex we we've gotten really great with the Mexican team and the Mexican team decided that they were getting um a lot of headaches and frustration with another vendor, hired vendor out of India. And we just got the news the other day that they're closing down that relationship with that Indian vendor and they're moving everything over tomorrow.

So, not only do we welcome the Irish, now we're welcome the Indians. We're making it all in Baltimore. skill that maybe I hope this helps you is the way we beat the Irish is quality quality quality extraordinary quality we'll focus like laser be quality and the reason why we're being the Indians is on time on time on time so I think if you deploy those things that'll help you and this is this killer client of ours is going to get is more than doubling in size we're going to be buying uh another4 million dollars for the robots to handle them. We're going to be hiring three $80,000 a year people to facilitate this plan.

Other reasons why I think uh reshing is going to continue happening and I heard a number of reasons in the room. One person was telling me about quality of the the material they buy in in this room. The quality that they buy versus what China brings over. Other things that the reasons why I think a lot of reassurance is going to happen is intellectual property rights. You know, if you uh have conceived of some idea in America, the person across the street is not going to steal it. And if they do, you have a rule of law and you go after them. In China, if the Communist Party is totally in favor, had no problems with them stealing or something, it's going to be stolen and you can't stop. And in some cases, if you want to move your plant to that country, you have to give them your source code. You have to give them your intellectual property for the privilege of living there, of having a factory there. How outrageous is that? That's one of the things President Trump talked talked with us about that. He said he's going to put an end to that. When he goes to China, he's going to talk to them about that. I love that because we intellectual property is how we differentiate ourselves.

We don't win jobs because we pay our people poorly. We don't win jobs because we allow that to go into the Chesapeake Bay. That's the bay where we where Baltimore's on. That's where we get our crabs. Everybody really loves Maryland crabs. It's Chesby Bay now, right? We want clean environment. So these are the things that are going to keep I think America going and and I think more reassuring to another thing is labor rates are going up consistently in China. Ballpark almost 20% a year year in year out. Pretty soon the Chinese labor rate is going to get pretty close to the American labor rate if it keeps on going in this trend. Plus, they have a 50% social security tax over there.

Number four, uh is a short distance. You know, if you're in America, you need to change from blue to red to green or whatever customer wins, change. I mean, today it's blue, tomorrow it's red. If you got a big boat coming in from China, you're getting whatever's on that boat. Again, quality is is critical. As we've discussed in the past, one entity that you should be aware of, and if you get a chance, who is Harry Moser, M O S E R, he has a really neat, pardon me, short, he has a really neat checklist so that you can compare your domestic price that you're making here in the US versus the Chinese or the Mexican or overseas price. and he goes through step by step. It's an amazing document that you can share with your client when they're making a decision. They're like, "We're thinking about moving it overseas. Populate this document for them." Again, Google Harry Moser. He'll help you concoct this document so that you can show your client why it makes sense to stay in America.

So, let's talk about manufacturing 4.0. The bottom line is how to keep your company healthy in the future. I believe it's all in in productivity. It's all in the people. If you look, this is the output per worker in 2016. India here is at about $17,000. China output per worker is about $25,000. You can see over here by far is the USA over $110,000 output per worker. We're the most productive nation in the world. our employees. They're extraordinarily productive.

I'm going to spend a couple minutes now talking about ways to amp it up even more to get even more out of your employees. How to get them more dedicated, more energized. Here are some tips that we've used, we've exploited, maybe they'll be useful for you. Just so you kind of put this in context, this is the day I bought Marlin's team. We were in Brooklyn, New York. It was uh a tiny shop. Every bend was done by hand. When I say every bend, we have eight men with arms the size of Popeye. One arm, the right arm. And they would hand bend, I kid you not, every day. 300 bends an hour. That was their job. 300 bends an hour. And then you know what they do the next hour? 300 more bends. They do that 8 hours a day, 5 days a week. And what they do the next week again. And that was their career, right? We had three guys missing fingers, two guys missing eyes, right? When they would go to work, they would walk. Every one of them, nobody owned a car. Nobody owned a home. Okay. The health insurance planners go to the emergency room and the retirement plan was called Social Security. All right.

Fast forward. Marlin's a very different place. But what we were doing is we were making bagel baskets. When you go to a bagel shop, we made the baskets. They look like this. Now, we do things like expanding metal baskets for material handling. This is a a Ford F-150. The steering columns, we make all the baskets that hold the steering column components and the hooks that hold all their high value parts that go through the production line. We also do big baskets that go into big dipping tanks and acid tanks. We do compartment back baskets like if you type in if you go to Granger, McMaster, MSC Global, all those companies, they use my baskets. We have a laser. My point is we're a real American factory. Okay? I'm not a policy war that just, you know, costs. Uh we we really make things in America. 100% America. We export to 39 countries. We import nothing. We buy everything from our sheet metals from the Newport plant in Crawfordville, Indiana. And our uh all of our stainless steel is from the Illinois plant. This is the president of Seammens. Uh this is our uh medium frequency welder. It's 10 foot x4t welder. press breaks, punches, robotic welding equipments from Lincoln, Cleveland, Ohio.

So, here's my suggestions on where to focus to get the most out of your employees so they can be more productive. It's all in the workforce.

The number one rule, the cornerstone of where I'm coming from, the foundation is you have to look at your direct labor like there are fixed cost. Many companies look at their direct labor like a variable cost. I insist that when you have when you contemplate your employees, you have to think of them as like a rent payment or mortgage payment or a car or as a as a bank debt payment. It's a given. you're definitely paying it. If you have that mentality, your employees are more dedicated. They're more engaged. They're more willing to give it their all for you. They're more willing to point out ways to uh improve your company. They know that you care about them. You're in this together. You're more engaged with them. You're more willing to train them because you know you want them to retire with you.

One thing that we do when we're recruiting talent and evaluating talent is something called the Polaris profile. We model all of our a rockstar employees, we set that as their target and then when we interview people, we use Polaris as a way to figure out whether or not they have attributes that are the same that will do well. So that's one way we when we're bringing in new talent, that's a technique we use.

Another thing that we do is we embrace safety. There's two companies here with extraordinary safety records. Uh and uh it it it's it was wonderful to discuss their techniques with them tonight. We also strive to have an amazing safety record. We've gone 525 days without a lost time accident. Over 3,200 days with only one lost time accident.

One thing that we've done is uh pursued a program called Sharp. It's a program through OSHA called Sharp. I don't know if you're familiar with it. I encourage you to pursue it. What it's all about is this. Most people when they think of OSHA coming to their front door, the first thing they do is they grab a cross and some garlic, right? That's the first approach, right? I recommend instead OSHA's other uh side which is their mentoring, their consultative approach. Bring them in, have them come in and give you suggestions on how to up your game, how to protect your network. Your employees will be very impressed with you that you're taking that approach to and you care about the well-being.

This is a picture right here, Secretary Aosta. He's in uh President Trump's uh director uh he's the secretary of labor and he came to us on manufacturing day and he's in charge of OSHA and this is us with our sharp award. We're one of five companies in the state of Maryland that have sharp. One of the benefits, one of the privilege of Shark because they're so comfortable with your process and your river is that they will not do a surprise inspection on things. Okay? Because they have comfort that you're treating your your employees well and you and you have their best interest in heart. Is that like employees know that you're sharp? They know you care about whether through a safety committee. I think these are all techniques that get your employees more engaged, more enthusiastic about working for you, more dedicated to being on your team in the future. Critical element about safety, focus on near misses. The near misses are the pe are the elements that are most likely to be ultimately be your next accident. So drill down on near misses. Be relentless. Do everything you can to make sure that nearness never can happen again. This is uh the governor coming to visit us when we have the first show.

Next topic is the skills matrix. We believe that a skills matrix is a great way to improve employee engagement. Many companies the way you get a promotion is by playing golf or having fears for plant management. That's how you get a promotion. That's how you get a raise. In our company, we have what's called a skills matrix where we show every single employees. The top of an Excel spreadsheet right here is in the lunchroom. And every single skill is detailed right here. If you learn one of these skills, you get a pay raise. will train you during working hours while you're punched in. The idea is that we want to teach you and show you how to get ahead. It's not by drinking beer with deodorant or playing golf, right? It's by learning these skills. This is what we care about.

Some skills are easy, you get one point. Some skills are hard, you get two points. Some skills are really hard, you get three points. Some are extraordinarily hard, you get four points. We use this technique to get people engaged and motivated and fired up to learn more things.

The other thing we do is we have a production bonus system where we give employees skin in the game. We make them shopkeepers. We make them entrepreneurs within our factory. And if they get your bucks in a twoe period of time because they think in a twoe period of time. They don't think in a one month period of time. They don't think quarterly. They don't think annually. They get a bonus for doing well in their little part of the world. We believe they'll be more engaged, more fired up, and they'll hit big bonuses, and they'll be um more involved in the company and and they'll stick around the company longer.

One benefit is we were able to get rid of the whole level of middle level employee, guys that walk around with the clipboards that say, "Hey, you're talking too much about the Ravens," or, "Hey, you're talking too much about the Warriors. You're going to the bathroom too much. It's demeaning. You're not treating your employees as professionals. You're not treating like them like addicts. By having a production bonus system, they're self motivated because they want to score. They want to hit their points. They want to get the bots.

Another technique we use is heavy emphasis on training. We spend 5% per employee on direct labor as a percentage of direct labor for training. This helps them improve their game. making make more out like for example the laser operator has less scrap more uptime the machine is making better quality parts highly recommend very vigorous campaign of training that gets them more engaged energized more likely to stay with you other techniques that we use is a a relentless focus on quality a relentless focus on engineering 20% of our employees mechanical engineers ers that are doing things like stress analysis. This is how we differentiate ourselves from China. This is how we encourage we short. We really focus on giving uh our clients something that's unique that you know a pedestrian that Mexican company or a low commodity Vietnamese or Chinese company can never offer.

Another thing that makes us different is quick focusing on big robotics automation so we can really push out products quicker than our competition so we can run laps around China. Lots of robotics. A lot of people talk about robotics is going to take over all of our jobs. I disagree with them. I think like in that Indian example I was telling you about earlier, we're going to hire three people because we're hiring we're building bringing in more robots. Now in India over here they're going to get to facilitate but over here in America we're going to be growing jobs because of robotics. Robotics I think increases jobs and it makes makes sure that you're not going to become extinct which means you'll have zero jobs. The the key thing about robotics is you want to kill things that are high uh chance safety incident. You want to also get rid of things that are repetitive and boring.

So the bottom line is thank you so much for attending. Thank you so much for spending some time with me. It's critical that you uh join us and try to help us change Washington. I hope you get a chance to text tonight uh that number so we can improve the policies in Washington. Thank you so much.

I am very passionate about USA manufacturing. I think it's the key to pulling up people from poverty to bringing them into the middle class. Having a strong and thriving manufacturing system will really uh improve the the the life of so many people and you're the key. We're the key. And I'm going to talk today about basically two topics. The first one is policy things, things that are going on in Washington just to keep you up to date with what's happening. And the second thing is some techniques that we've used at Marlin to improve employee engagement, to improve uh the ability to uh be competitive in a very challenging uh environment where you have Chinese competitors, Mexican competitors, Canadian competitors that are very formidable. We use a number of techniques that I believe you can use. you can uh cut and paste into your facility. So th those will be the two elements that we talk about today.

Uh for starters, as we stressed, American manufacturing creates jobs in our country and they're great jobs. They're amazing jobs. This is Maxi. She's an employee at our factory. She's in charge of all making all the fixtures and out of wood and and materials like aluminum uh that make the molds that hold our baskets that go down the production line. Why is American manufacturing so critical? Because it's a middle class job. $82,000 a year, you can see right there, is the average wage of a manufacturing worker. $82,000 a year. If the company is an exporter, on average, they're paying $93,000 a year. This is extraordinarily good money. 97% of American manufacturers pay health insurance. These are good middle class jobs. They offer health insurance. They offer 401ks. This is the way to pull yourself out of poverty.

First, we're going to talk about policies. What's cooking in Washington? Being competitive is critical. We have to have a team, a factory that can thrive and prosper in a very competitive environment against countries where they don't pay the their employees well, where they foul the environment. We take great care of our environment. But how do you do that? We have to have a more competitive uh uh playing field. Uh I think John F. Kennedy said it great. Uh he said this to the National Association of Manufacturers in 1961. We cannot afford to wait and see what happens while the tide of events sweeps over and beyond us. We must this use this time as a tool, not as a catch.

I had the privilege of meeting President Trump to talk with him about what small and mediumsiz manufacturers need and what's cooking in Washington. This picture happened uh that's me right there handing his him his card right before we walked into the Oval Office. We had I had the privilege of chatting with him and discussing with him initiatives and things that we need as manufacturers to grow our economy and to help manufacturing in our nation. The reason why we were there was because we were sharing with him the results of a survey that the National Association of Manufacturers takes quarterly. And this this result asks, are you optimistic or pessimistic about the future? And in this quarterly poll that over 93% of American manufacturers were optimistic about the future. That is the highest poll numbers in in the since the inception of uh manufacturers being pulled uh about what their enthusiasm is about the future. 93.3% by the way that poll now been done three more times during the Trump administration. And again it's stayed above 90% on average during those three polls.

Why is that? Well, by the way, it's not just manufacturers that are enthusiastic. It's small business in general and it's the consumer. Everybody is getting more and more optimistic about the future. This is actually a tweet from the meeting. Uh you can see me standing right there and uh this is actually a positive tweet. A lot of times president does some tweets are not so positive. This one happened to be a positive tweet talking about American manufacturers visiting. This is a group of uh uh small manufacturers that visited uh with the president. I've also had the privilege of meeting uh a well-known Indian hooer uh vice president Pence and we talked right before he was sworn in and we also talked uh once he was already president and each time we talked for an hour about small and mediumsiz manufacturing and ways that we could grow uh our nation's manufacturing.

President Trump when we were in the Oval Office said to us, "We're going to bring back manufacturing to the US." Vice President Pence told us, "It's unbelievable how anemic our economy has been over the last decade or so. It's unacceptable. We should we have to get to four and 5% growth." You guys got to remember there was a quarter under Reagan's time where it was over 7%. This is doable. We should not be complacent and think a 2% or 1 and a half% GDP is acceptable. It's unacceptable. Yet this is how you pull people out of poverty. I created this acropolis, what I call the jobs acropolis. These are the things that I think the the reason why people are so enthusiastic. So why is small business, why is manufacturing so optimistic about the future? It's built on these columns. These seven columns are what is driving this excitement of why there's going to be good news in the future. Let's go through each one.

The first one is uh let me step back a second. when I had the privilege of meeting uh uh then governor but now Vice President-elect and then ultimately Vice President Pence, he said, "The reason why America is going to thrive and prosper and our manufacturing sector is going to prosper is because we're going to cut and paste what we did in Indiana for the nation." And he said, "You know what the three things were that we did so well in our state? The three things we did so well was number one, we were a right to work state. Number two, we were a low tax state. And number three, we're a low regulation state. Because of those three things, our manufacturing uh uh culture was extraordinary. And because of that, places like Evansville have a 2% unemployment rate. What a tribute to the community. It's fabulous. You guys are doing a lot of things right here. Well, Vice President Pence said to us, "We're going to use that playbook for America as a whole."

When Vice President Pence was meeting with us, he said to us, he reminded us that both him and his uh and Trump's grandfathers were immigrants. He was talking about how humbled he was to be in this position. He was choked up and described how passionate he was about the American dream. And it was a sense of responsibility that we spread the American dream and and grow the middle class in our country. The bottom line is he said to us, "We've got to make America more competitive so it's a better place to create jobs." Many people in Washington think when when they use the word manufacturing, they think this picture is a picture from the 1950s in Pittsburgh, right? We're all desoiling the environment, we don't treat our employees well. That's what the common sense conventional picture of manufacturing is to many politicians in Washington. Vice President Pence and President Trump don't think that way. They think we're great job creators and they think we they need more of us to make the economy better.

One other thing I wanted to mention, the majority of manufacturers are small. People don't realize this. Many people think most manufacturers are like the size of General Motors or the size of Honeywell or Emerson. They're big. They're huge. They're very valuable to our economy. But more than 50% of factories in America of of employment in America are those little paths. Matter of fact, there's 227,000 factories in America. 225,000 of us are less than 500 employees. So, we contribute a tremendous amount. Now, the big guys are critical because they're they're our best clients, but it's the little guys that's where most of the action is.

So let's talk about why the economy is going to pick up and let's talk about why is the optimism justified. Why are jobs going to be created throughout the nation? Number one, US energy. I had the privilege of speaking with one of your colleagues in the room uh that works for a coal company. There's been tremendous reduction in regulations for coal. there's been tremendous uh ability for uh America to start unleashing our unbelievable uh what we have underneath the ground. Uh and we're allowed to exploit that again. That's going to drive down the price of energy and that's going to make our um the value ad that we offer easier because the price of energy is much more expensive in Korea. It's much more expensive in China. It's much more expensive in Europe.

This is only one of the differences. And if we unleash the American uh energy system, the America the the unable untapped value, everything from shale to fracking to coal. Our costs will be lower and we'll have a more resilient economy and we'll have a stronger manufacturing base. This right here is James. If you Google New York Times James Branch Marlon Steel uh from October of last year, they did a full piece on James. He runs our wire for one of our wire forming robots. You can see it right there. He's an interesting person and a great case study for why American manufacturing is great. James used to deal drugs on the corner of Baltimore City streets and he made good money, fast money. He also got in big trouble. He did time. He spent time in the big house. He did his time. He left. He reformed. He started working at Popeye's making minimum wage. And then you know what? He said, "I need to make more money." So he started working for a manufacturer and he made so much money that he put his daughter through college. James is one of our best employees and he he runs a quart million dollar a number of quart million dollar robots. That's the kind of good thing that manufacturing does for our society. And there's a thousands and thousands of stories of James Branches and that's what it's all about. Bottom line is domestic energy makes it easier for guys branch to get a job because if the costs are lower for the American economy, for the American factories, he'll get more out of bats, we'll win more jobs and and he'll get more hours. He'll get more overtime.

Number two is infrastructure. Our infrastructure is woeful. We have old ports. Our airports, I don't know how many of you have uh traveled overseas, but if you've been to the Beijing airport and Shanghai airport, they're gorgeous. If you've been to Laguardia or JFK in New York, they're they're basket case. They're third world. Our our infrastructure is crumbling. There's a bridge in it right near my factory. It was built in 1916. And when you drive over it, you you know, if you had dentures, they'd fall out. Okay. It's unacceptable how many potholes we have and I think the thing hasn't been repaired since 1916 when it was built. We need to reinvest in infrastructure. That's roads, that's ports, that's uh all elements. Uh and we have not been doing proper investment.You can see this chart. In the 1970s, we're spending almost 3.8% of our GDP in reinvesting in our infrastructure. Now we're down by the under 2% world. The American Society of Civil Engineers is grading our country's infrastructure as a D+. We're America. We should be an A+, right? So this is something that the president is committed to doing is spending over a trillion with a trillion dollars in infrastructure investment. So we have the best potholes, so we have the best roads, so we have the best airports. We deserve it. And that's going to help American manufacturing because there's entities like Caterpillar that is going to make bulldozers for it. And all of us use trucks to drive down these roads or trains that go on these uh uh you know and and moving our products, we can get it faster to market.

Next is tax reform. This is a big topic right now in Washington. Uh all minds are focused on tax reform. It's critical we get this passed. JFK, John Kennedy said about taxes in 1962 when he was pushing to get the taxes cut. He said, "It's a paradoxical truth that taxes are too high today and tax revenues are too low. And the soundest way to raise revenue raise revenue in the long run is to cut the tax rates now. And if you do it, you'll create a more prosperous and expanding economy." JFK did it and it caused a wonderful acceleration in the economy. Reagan did it and pretty soon I believe Donald Trump is going to be doing it. Mind you, the last time we had tax reform, it was this pitch that explained to the American economy why it was a good idea. 1986. There's probably a number of people in this room that were not born in 1986. Okay, that's too long. Our tax code is totally uh inefficient for being a global player.

When Donald Trump went to the National Association of Manufacturers, I was I had the privilege of intro of introducing him and welcoming him to the NAM before he went on stage to announce to the manufacturers. This is not last Friday or Friday before. Here's the the crux of Trump's plan. Number one, he's going to simplify it. Right now we have seven brackets. He's bringing it down to three. Who's the losers? It's going to be our H&R Block. Okay. There's going to be less uh tax accounting which is a wasteful activity. He's going to lower the corporate tax rate specifically from 35% hopefully down to 15%. There's going to be a lot of tax loopholes that will go away. He's going to eliminate the death tax. He's going to also take um the ability to repatriate cash. We'll talk about that more in a couple minutes.

A couple other things it's going to do. What by the way, when we're talking about simplification, we're talking about 90% of American filers will use a postcard. It's that simple. and small businesses. Again, that's 90 something% 97% of American manufacturers who are LLC's, who are PAS students, who are escorts, their rates going to go from the current personal rate, which is 39 plus%. Down to 25%. That means we're going to be more competitive with Canada where they're at 15%. And we'd have instant expensing. Instant expensing means when you go buy a robot or some automation or a tool so your employees can be more competitive against Mexicans or more competitive against Chinese, you can write it off that year rather than spreading it over 5 years, 7 years, 10 years, right? You can write it off that year. It's going to give a lot of testosterone to a lot of business owners to go out there belly up to the bar and make it happen. buy that tool, buy that technology so your employees can be more effective and more efficient. Bottom line is some economists are saying it's going to add $12 trillion to our GDP. We're going to invest $3.3 trillion into the economy and most importantly 6.5 million jobs will be created.

Bottom line is tax reform is critical to manufacturing jobs. There's a little chart and I'm going to provide this uh PowerPoint slideshow to uh Shannon and the team and she'll share it with you. But you can watch tax reform going through and if it's tracking on these days ballpark we're going to it's going to work out. So green is what's behind us and you can see every single week or every single milestone where we are. So you can see whether or not this is going to play out. Bottom line is right now we're the red number. Okay, that's our marginal top tax rate for uh our companies 39%. The average is down here. It's hard. If you're a GE, how do you compete with Seammens? Right? You can't. You can't because their rate their rates are so much lower than us. So that means our employees are going to win less jobs and they have less opportunities. We have to make this right so our employees can have a level playing field. Bottom line is a forward-looking tax policy is an economic imperative.

This is Kenny. He's our fixture maker. He makes the samples. This is a basketball making for Volvo. I can't stress enough to you how important this tax reform is in order politicians have to get in line so that it can protect our interests so that we can grow our jobs and grow our economy. Rarely do you hear of somebody who's speaking to you say to you, "Please get out your cell phones right now. Please, I implore you and go to go to that number and text act on tax." They will support. They will give you updates and they'll help you get your politician to make a change and hopefully vote the right way so that we don't have a situation where we have an antiquated tax system. I encourage you to text to 52886 and give this to your employees and have them do it. Text act on tax. No spaces. act on tax. Please do that because that way we can get the message out so manufacturers have a better shot at being more competitive and we can grow our economy. So again 52886 act on tax no spaces.

Next is repatriation. So part of this tax reform is that we have three to 5 trillion, it's unclear,3 to5 trillion of cash parked overseas. What does that mean? So if you make cash profits, let's say in Switzerland or in France overseas and you're a company, if you bring it back, not only do you get taxed at the French rate, but you also get taxed when you bring it home. We're the only country that does this. Everybody else has what's called a global tax system. We actually tax a second pass. So you know what happens with our companies? They don't bring it back. It sits overseas. They're waiting for that cash to be tax in a rational way. This new tax plan allows them to bring home that money. It's called repatriate that money back into our system.

This is part of the reason why I believe the American economy is so optimistic about the future because soon 3 to 5 trillion, nobody knows exactly 3 to 5 trillion is going to come home. And when that comes home, you know what they're going to do with it? They're going to buy new factories, build new factories, buy new equipment, hire more people, hire more PhDs, hire more engineers, do a new marketing campaign. They're going to do something with the money. Now, some of it will be used for dividends, some of them will be used for cash buybacks, but that's good for your 401k, right? Right? That's good for the pensioners, right? So, what's going to happen is uh this is going to be another element for why there's optimism and what justifies 93.3% of small manufacturers and manufacturers in general being enthusiastic about the future. This is going to be a sugar rush for the economy when this happens.

Next is trade. So bottom line, trade is very good for America and a lot of times you'll hear people badmouth trade. So you can see um the blue line is manufacturing output and the red line is how much our manufacturers are exporting. So you can see despite the bad mouthing of NAFTA, despite the badmouthing of WTO, Korean uh free trade agreement, all those things, what goes up pretty consistently, except for the bad recession of 2008, pretty consistently, we're shipping more and factories really count on exports. We need a thriving trade. We need thriving exports. And you can see how important it is to all of us as that own factories and run factories. It's almost 50% of American factories output is actually exported. So the blue line is total output of all factories. The orange line is what we export.

It's a huge contributor to our well-being. So, for example, we make baskets for caterpillar. We ship it to Poria. We ship thousands and thousands of baskets to this caterpillar plant, but it's a little misleading. Why? Well, because more than half of the tractors, the bulldozers that Caterpillar makes, they export. So, really those baskets are used for exports. One thing we talked about with Vice President Pence was tell us about this trade topic because for years I was a big proponent of NAFTA. For years I was a big proponent of TPP, the 14 countries of that are on the Pacific Rim coming together to make a huge multilateral deal. I thought this was going to be great for our factories. I thought this would be great for America. And I asked uh we asked Vice President uh Pence why is President Trump so much against the TPP was one of the first things he did was get rid of it. What's the reason? And he said it's real simple.

When you get into a deal with 14 people, Peru, Vietnam, Japan, America, Canada, etc. You water down the impact of America. We're a huge country, but if we're at the table with 14 13 other entities, we're watering ourselves down. We're even Japan gerilla if it's US versus Peru bilateral or US versus Vietnam bilateral. So, Vice President Pence explained to us the benefit of doing a series of bilateral deals is going to be much better for the American factory worker. It's going to be much better for the American factory because a series of bilateral deals where we are the 800 lb gorilla is much better than being watered down on a multilateral deal like TPP or Trans-Pacific Partnership. So that was the justification. It sounded interesting. It sounded good to me. He changed my mind. But that's his push and that's the reason why they think trade will be better for America because we'll have our interest protected better by a series of many many by bilateral deals as opposed to a few very large multilateral deals where our uh heft is worked down. Again, I got to stress trade is critical. We got to make sure we keep it going. One in three acres in America is exported and more than 50% of American factory goods are exported.

Next is regulations. One of the things we talked about Vice President Pence with is whatever happened with Carrier. And he said, you know, why didn't Carrier leave? Carrier was actually the last company in their industry that was still in America. All the other companies have already fled. They already left to Mexico. They were the last survivor in India. And they were in India, as you know. And why did they why did they decide to close down? Because there was 50 new regulations in the final two years of the Obama administration. It was a straw that brought the candles back. According to Vice President Pence, Trump picked up the phone and said to them, "I'll roll them back. Let me know what they are and I'll get rid of them. and I want you to stay here, America. That apparently, according to Vice President Pence, is the backstory of why carrier state.

Winston Churchill has my favorite line of regulations. If you have 10,000 regulations, you destroy all respect for the law. Here's the problem. American manufacturers have 297,000 regul literally 297,000 regulations on them. It's a lot more than 10,000. Now, I want regulations because I want clean water. I want regulations because I want clean air. I want I've been to China. It's foul. China is you have you you it's scary to breathe in China. Okay. And I I'm from Maryland and I'm a crab bigot. Okay. I can't eat crab cakes anywhere else in the world. All right. So, we want clean water because we have the Chesapeake Bay and that's where our crabs come from. Right? So, we have to have pristine water. So, these are given. You have to have clean water. You have to have clean air. You have to have clean soil. You have to protect your employees, right?

That being said, you still don't need 297,000 regulations. That's over the top. That's tying up our factories. And that's the reason why companies like great companies like Train Leave America, right? Because they're escaping our overregulation. We need rational regulations. This is Chris Elwood. He's one of our mechanical engineers. Bottom line is if we have rational regulations, not over the top, not burns, keep the air clean, keep the water clean, our companies can be competitive. 87% of manufacturers say if we could have rational regulations, they'll invest more into their factories. They'll do more R&D, more wages, more capital into their factories.

This is a big dollar amount. So if you look at the orange bucket right here, the average small manufacturer that has less than 50 employees is spending on average 34 grand a year per employee. So think about your employee who's working. He has 30 here or she has 34 grand of burden that he's carrying or she's carrying when they're working. If we can get that down to $17,000, what a win for the American economy and keep the air clean and keep the water clean, this is what we need so that we can have a more viable economy. President Trump has vowed to have a twofor one ratio. Every new regulation he's going to take away two that don't make any sense. And if we could repeal it at that rate, I think our our this is justifi just justification for why we're going to have an expanding economy.

By the way, the reality so far to date, he's actually been cutting 16, not a 2:1 ratio. He's beating his record. He's he's cutting back 16 to one. There's already been some wins. He's done pipeline, Dakota pipeline. These are 80,90 $100,000 a year welding jobs that are being created that would never have happened because they would have been scuttled because of regulations. He's also ended the war on coal. This is good for our country because it makes uh our um our feed stock the the you know the energy that we need to power our economy. There's another thing that people haven't talked about when we talk about regulations. It's the judges. He promised he would have a Scaliaike pick for his judges. Well, already there's a Supreme Court Justice Gorsuch that was picked who's in the mold of of Scalia, which is a good thing. And he's already nominated 60 people and there's 160 that are going to be filled real soon. and the the the regulations, how they're interpreted, how the judges are interpreting the rules, that's going to have a big impact. And it's not just for a year or two. These judges sit on these benches for 15, 20, 30 years in some cases. This is going to have in 2040, 2030, we're going to have people still interpreting rules because of uh his picks that he's making.

Now, lastly, is healthcare reform. This is Nathan. He runs one our wire forming companies. And uh he was actually not last Friday, the Friday before he actually was in the Oval Office and uh President Trump signed the proclamation for manufacturing day on October 6th and gave the pen to Nathan who was standing behind him. So Nathan runs our wire forming machinery. Right now there's taxes on health insurance companies. There's taxes on our medical device companies. There's taxes uh when you uh for for the companies so that they have to raise their rates to us. Uh for example, in Arizona, the premiums have gone up over 116%. I know our premiums have gone up over 100% over the last 8 years. And I know that we've lost our health plan four different times in the last eight years.

So, where are we with healthcare? Well, it's it's not as as rosy as we would hope at this point. Uh the House succeeded in putting across the line a bill. The Senate failed. We had the privilege of meeting uh Senator McConnell uh from uh Kentucky, Leader McConnell from Kentucky, and the way he put it is, are you guys familiar with the 8020 rule? He said to us and all manufacturers generally are familiar with the 8020 rule. He said 80% of my time is spent with four senators. Okay. He is constantly negotiating kissing up to these four senators trying to get them to pay and bottom line is three years show voting and that's what scuttled it in the Senate.

Um, recently, the other day, President Trump just used his pen and is now allowing us soon to buy health insurance from other states. That should be a very good thing because competition is a good thing. I know in Maryland we're down to like four companies that we can buy health insurance from. If I could buy from Kentucky or if I could buy from Indiana, you guys might have a better plan than what I'm getting. So, it's going to open up the game and I I I won't have a cartel that I'm dealing with. It's got to be good for me and hopefully in reciprocal uh Indiana and Kentucky will have a better deal.

So, again, if these policies are important to you, and I hope they are, uh there's an organization called Friends of Manufacturing, and you can text Friends to 52886 and you can get on their list. So you can be uh advised of updates of new policies and things that are happening in Washington so that you can hit the senator or the congressman at the right time. Hey, text now about this matter and you'll be on the list and you'll be and you'll be engaged. And I implore you to text 52886 the word friends and you'll be uh enlisted into this army. We need an army of people alerting the congressman, alerting the senators about sensible policies to protect manufacturers.

So, that's basically a policy update, policy briefing on what's cooking in Washington. I'd be happy to answer any questions about that. Uh afterwards, but first, I was going to talk about employee engagement. I understand uh Evansville is uh um dealing with 2% unemployment. What a wonderful problem to have. But it is a problem, but it's a it's a testament to uh a wonderful economic system you got going on here. Uh how do you attract talent? How do you retain talent? How do you engage talent when you have a 2% unemployment? That's really tough. Oh, I'm sure if they're skilled, it's probably a half a percent. If they're a skilled employee, probably even worse. So that I'm going to share with you some techniques that we find useful. But the bottom line is the way to keep manufacturers healthy, it's all in the people. It's all about people.

One of the most important elements that makes American manufacturing unique and different is how productive our employees are. They're extraordinarily productive. This is a chart of some of the biggest countries in the world and how productive their employees are. And you can see here um for example India they're less than 20 grand a year revenue per employee. Uh this is value added and you can see up here Holland is close but number one by far is the USA.

This is an incredible document because it shows how unbelievably productive the American employee is and the American worker is. I'm going to share with you some techniques that Marlin uses to get them even more productive, to get them even more engaged, to get them even more dedicated, to get them to have less turnover, to have less churn.

Just to scroll back a second, this is what my factory looked like the day I bought the company. Just so you guys know, a little context. The company was established in 1968, Marlin, and I bought it in 1998 when it was 30-year-old company. It was at 5,000 square ft. We had three people without fingers. We had two people without eyes. It was a Charles Dickens model. Okay. Uh there was a little sign. You can see it right here. It says, "Be careful. Watch your step." This is a picture I took on the very first day. What a what an omen. Okay. I should have really looked at that sign a little more carefully. Uh there was no rules about safety glasses. Um you could see the M. This right here, that was a hand bending machine. So we had eight guys that take wire and put the wire down and they would hand bend every bend.

We made bagel baskets. So when you go to like a bagel shop and you order a bagel that the little wire baskets that hold the bagels, these this is we made we were the biggest bagel basket manufacturer in the world. And we made these bagel baskets all day long. And we had eight guys with enormous arms like pot size. Their white worm was the size of Popeye. And they would bend 300 bends an hour. And then you know what they would do the rest of the other seven hours? 300 more bends an hour. And then you know what they do the next day? 300 bends an hour. They would do that the next week, the next week. And that was their livelihood. We had eight guys with enormous arms. They also occasionally would miss and they' hurt their fingers and it was plus or minus a quarter of an inch.

But it worked. Do you know why? Because when you're in the bagel basket business, your client bagel shop, they don't even own a tape measure. So, their tolerance is plus or minus a bagel. Okay? If the bagel doesn't fall out of the basket, success, good quality. Okay? That was the world that I bought. Okay? And it was a fine world because we were I don't know if you guys recall, but in the '90s, the bagel basket business was um doing very well. was exploding because all of a sudden everybody was starting to eat bagels became highly common and they started it wasn't just a New York City thing. It wasn't uh it was just expanding across the nation. So we were uh shipping bagel baskets all over the place and uh it was working out really well for us. Um and this is what I'm talking about. This is what the bagel baskets look like. That's what it looks like.

So, we were making thousands of these bagel baskets and everything was perfect and then two terrible things occurred. This happened right after I bought the company. I had no idea this was going to happen. The first thing was the Atkins diet. I don't know if you guys recall the Atkins diet. This is a diet where you're not allowed to eat carbohydrates. What's the world's biggest carbohydrate? A bagel. Okay. So, what's the first thing you do? You stop going to the bagel shops, which means that all my clients start going bankrupt. It was terrible. Who would have known this? Okay, because we just came out of this bagel fat where everybody's eating bagels like crazy. People that never ate bagels before all of a sudden are eating bagels. All of a sudden, nobody's eating bagels.

Second terrible thing occurred. China, they figured out, hey, we can go after this commodity market. We can sell these baskets into America because the quality doesn't matter. It's just got to be plus or minus a bagel. That's the kind of world China likes to be in, right? That was the world we were in. But they didn't even notice us until they noticed us. And unfortunately, that's right after I bought the company. That is a bad place to be. Okay. So, we had two horrible things occur soon after I bought the company. All of a sudden, sales started plummeting. All of a sudden, we were hemorrhaging cash.

And just to show you how bad it was when I talk about Chinese impact on us. So, we were selling bagel baskets for like 12 bucks a th $7 in steel. And I made, you know, the variable was basically five bucks. That's for the rent, that's for the Christmas party, that's for the 401k, that's paying for the fax machine, right? We lived on the five bucks, right? China started delivering bagel baskets into Manhattan for six. That's no business, right? Because if your competition is coming in at six and your material cost is seven, you know what that's called? Death. We were dying. We were just plunging down, hemorrhaging cash, and it was a very bad situation. I didn't have any ideas and I was in a bad way because I had all these employees and I had no business model and we were floundering around trying to figure out what the heck we were going to do next.