Over the years, Marlin Steel has produced numerous custom industrial wire products for a variety of uses. From custom steel hooks for mounting other metal forms, to parts washing baskets, to heat treat trays, Marlin’s degreed engineers have conceptualized, tested, and produced hundreds of unique designs.

This extensive experience in handling a variety of production demands, combined with extensive training to keep up with new developments, has helped Marlin’s degreed engineers consistently overcome the unique challenges by finding the right combination of wire materials, features (handles, lids, etc.) and more for each design.

Some of the notable industrial wire products that Marlin’s degreed engineers have created include:

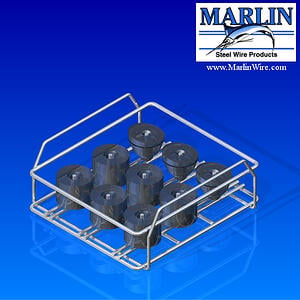

Material Handling Basket 288004

This basket was designed to hold a series of hollow, cylindrical objects through a simple parts finishing process. This process required that the parts being handled not be obstructed in any way—the chemicals used required free access to the parts and also needed to be able to drain away just as easily.

This basket was designed to hold a series of hollow, cylindrical objects through a simple parts finishing process. This process required that the parts being handled not be obstructed in any way—the chemicals used required free access to the parts and also needed to be able to drain away just as easily.

So, this basket uses a series of pins around which the cylindrical parts would rest instead of a wire mesh cage. This would let the parts rest on the pins with little to no wire mesh to interfere with the finishing process.

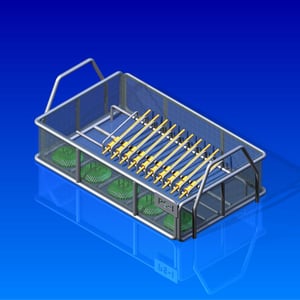

Medical Instrument Tray 02235002

This wire mesh tray was designed for a medical product manufacturing process involving syringe and disc-shaped objects that had to meet extreme sterilization requirements. Using a series of offset wires allowed the syringes to be set at an angle so that runoff from the sterilization/cleaning process could drain away easily. The other components in the tray were held in place with just a few pieces of wire to prevent them from sliding during processing.

This wire mesh tray was designed for a medical product manufacturing process involving syringe and disc-shaped objects that had to meet extreme sterilization requirements. Using a series of offset wires allowed the syringes to be set at an angle so that runoff from the sterilization/cleaning process could drain away easily. The other components in the tray were held in place with just a few pieces of wire to prevent them from sliding during processing.

Two handles on the outside of the frame made the tray easy to carry by hand for staff in the cleanroom, and even served as guides for stacking the baskets neatly. The frame of this medical industry tray used grade 304 stainless steel to keep the temperatures and chemicals used in the sanitation process from damaging the basket.

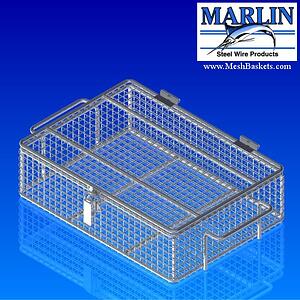

Ultrasonic Parts Washing Basket 1151001

This industrial wire form was created for a heavy-duty ultrasonic parts washing process where the basket and its contents were expected to be rotated upside down mid-wash. The sheer strength of the ultrasound generator would shake apart weaker, thinner wires over time—which mandated the use of strong, thick, securely-welded wires for the design.

This industrial wire form was created for a heavy-duty ultrasonic parts washing process where the basket and its contents were expected to be rotated upside down mid-wash. The sheer strength of the ultrasound generator would shake apart weaker, thinner wires over time—which mandated the use of strong, thick, securely-welded wires for the design.

To keep parts from falling out when the basket would be flipped, a strong wire mesh lid was added to the basket and secured with a heavy latch that would keep it from coming loose. Keeping the open space between wires as wide as possible helped minimize their interference with the ultrasound vibrations—helping maximize the effectiveness of the cleaning process.

The ultrasonic cleaning basket used stainless steel to resist exposure to the mildly caustic cleaning chemicals used in the cleaning process. The corrosion resistance of stainless steel would prolong the useful life of the basket—helping the client save money on the cost of having to replace them every few months.

These are just a few of the examples of custom wire forms that Marlin has made for different industries. See more examples of how Marlin Steel helped other manufacturers meet their goals by checking out the Case Study Compilation at the link below.

.gif)