Expanded Metal Material Benefits

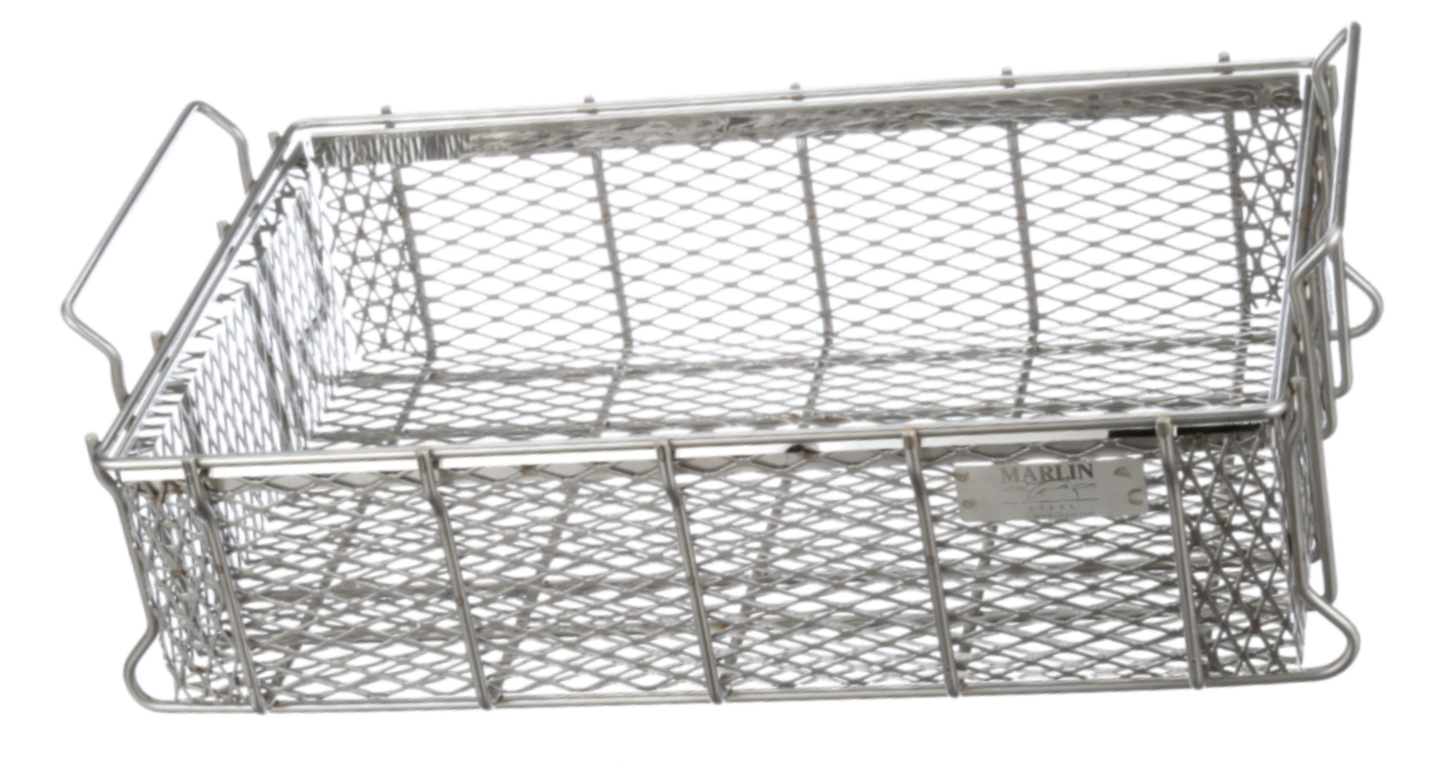

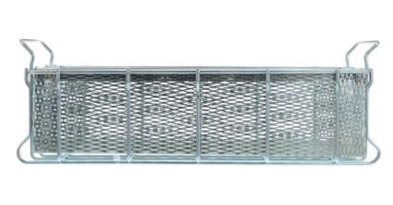

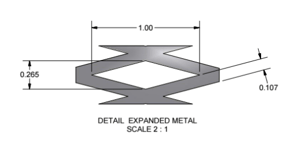

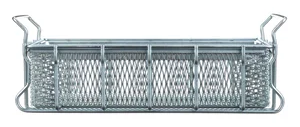

Expanded metal is a single piece of metal stretched to form a specific shape. This type of material requires less welding and is stronger than wire mesh of the same thickness. Expanded metal baskets also offer more open space and are more economical than perforated sheet metal since very little metal is scrapped in the expanding process. Due to these benefits, baskets made from expanded metal are ideal for environments where strength, durability, resistance to harsh environments, and effective sanitization are important.

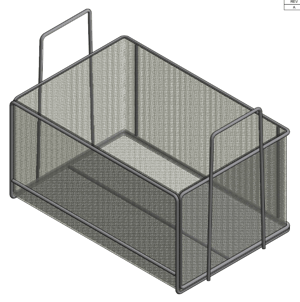

Here is an overview of expanded metal’s notable benefits:- Durability: Expanded metal baskets are made of a single piece of steel, which is a long-lasting, easy-to-clean material that can withstand caustic cleaning chemicals and other extreme conditions. They can also hold heavier items without breaking or bending.

- Versatility: These baskets can be adapted for any heavy-duty material handling application in the food processing, agricultural, manufacturing, or industrial sectors. Casters or handles can be added easily for portability.

- Cost-effectiveness: Because they produce minimal scrap material, expanded steel baskets are less expensive to produce and maintain than wire or plastic baskets.

- Enhanced ventilation and visibility: Designed with diamond-cut patterns, expanded steel baskets allow for excellent visibility and ventilation, which are especially important in food processing. Produce must be washed and dried properly before packaging and shipping. When used for storage, these baskets allow operators to quickly and easily identify contents.

Industrial Applications for Expanded Metal Baskets

Used extensively in the agricultural, industrial, food and beverage processing, and other sectors, expanded metal baskets naturally lend themselves to applications such as:

- Heavy Metal Part Storage: Industries like automotive and aerospace frequently need to hold and move heavy metal parts safely between operations, cleaning, and other treatments. Heavy-duty expanded metal baskets offer the strength, chemical resistance, and airflow to make these safer, more efficient processes.

- Shot Peening Parts: Shot peening involves bombarding parts with small, round balls of varying materials at high speeds. It is designed to reduce fatigue and stress damage on fabricated parts. This process is made easier with durable expanded metal baskets, which easily stand up to the repeated impacts of the shot media.

- Shot Blasting Parts: Similar to shot peening, shot blasting can also polish or clean parts. Expanded metal baskets can tolerate prolonged, repeated high-pressure impacts while parts undergo shot blasting.

- Degreasing and Cleaning Components and Brackets: Removing grease, lubricants, and other contaminants from parts is necessary to prepare these surfaces for additional treatments or to improve performance. Degreasing products typically contain caustic chemicals and solvents, so non-reactive, stainless steel expanded metal baskets enable faster, more effective degreasing without compromising results.

- Aircraft Parts Cleaning is one example of a cleaning process involving extremely harsh chemical cleaners. The aerospace industry requires parts washing baskets made of expanded stainless steel, which resists corrosion and facilitates efficient parts cleaning.

- High-Agitation Parts Washing also uses expanded metal baskets to withstand rough agitation cycles.

- Part Organization/Stacking: Managing and tracking parts and components during manufacturing processes can be simplified with sturdy, versatile expanded metal baskets that maintain their shape and strength during transport, stacking, and nesting.

- Fire Safes for Warehouses: Expanded metal baskets can serve as fire safes to hold cases containing valuable materials, documents, or parts by keeping them safely isolated from the worst damage due to fire.

Contact Marlin Steel: Your Source for Quality Expanded Metal Baskets

At Marlin Steel Wire Products, our decades of experience and commitment to excellence in quality and customer service are demonstrated by our ISO 9001:2015 certification and our numerous awards and recognitions. With our Quality Engineered Quick® approach, our 100% made-in-the-USA expanded metal baskets and other products are fabricated efficiently and delivered promptly. We offer in-stock expanded metal baskets and custom metal basket solutions to fit your unique application.

Contact us or request a quote today to see how we can provide a solution for your project.

.gif)