Aerospace parts must withstand extreme stress from a variety of forces, including air pressure, inertia forces, and impact stresses during takeoffs and landings. Known as loads, these forces and movements can apply extreme stress to an aircraft’s structural integrity. Aerospace parts must be able to continuously withstand these stresses to keep the aircraft intact and its passengers and crew safe

It’s not surprising then that aerospace manufacturing must abide by the strictest of manufacturing requirements. One way that aerospace manufacturers ensure their aircraft parts can stand these tests is through Finite Element Analysis (FEA) testing – and using FEA-tested custom wire baskets for transporting and washing aerospace and aviation parts.

QUICK LINKS

- What is Finite Element Analysis (FEA)?

- Why is FEA Important?

- How is FEA Used By Marlin Steel?

- Why Marlin Steel Uses FEA Testing for Aerospace Baskets

- Case Study: FEA in Custom Wire Baskets

- Case Study: FEA in Aerospace

What is Finite Element Analysis (FEA)?

Finite Element Analysis (FEA) is a simulation tool that is used to analyze and test components and systems strengths and behavior under environmental conditions. In aerospace manufacturing, FEA software is used to predict how aerospace parts will react to structural and thermal loads.

According to the Autodesk website, FEA is “a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects.” By using sophisticated simulation technology, like FEA, extra material models are not required for traditional testing, which saves time and money.

Why is FEA important in Aerospace?

Finite analysis software is used to predict how a product will withstand its environmental stresses by simulating the conditions it will be placed in. These conditions can include real-world forces such as temperature, vibration, points of contact, distribution of weight, quality of welds, and exposure to certain chemicals. These factors can affect the structural integrity of the product. In aerospace manufacturing, there is no room for error. Aerospace parts must be tested thoroughly before being released for distribution.

Since FEA tools test multiple elements at once, it makes for a more effective analysis than traditional methods. There are several other advantages to using finite analysis software vs physical prototype testing, including:

- Faster testing speed (minutes or hours instead of weeks or months)

- Reduced materials expense because of the ability to test designs without needing multiple physical prototypes

- Reduced labor because less manpower will be needed to conduct a simulation vs physical testing

- Ability to simulate years or decades of use, increasing test thoroughness and predicting future aerospace product behavior

How is FEA Used by Marlin Steel?

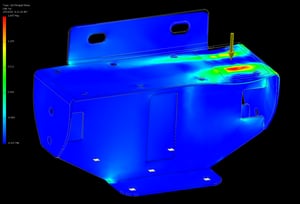

Marlin Steel uses special Autodesk FEA software to conduct virtual physics simulations that emulate the effects of different stresses on our basket designs. The simulation takes a 3D basket design and breaks it down into thousands (or hundreds of thousands) of “finite” elements—such as cube shapes.

Next, the software runs these finite elements through a comprehensive series of mathematical equations to simulate the effects of different stressors and conditions on each part of the basket. The cumulative effects of these various factors are tallied up on the computer that's running the software and applied to a simulation of the object as a whole. This provides an accurate and reliable simulation of how a stainless steel basket will react under stress and other environmental conditions. Plus, this process of conducting virtual steel analysis takes mere minutes—saving considerable time, labor, and materials compared to manual testing processes.

For many major industrial parts handling/processing applications, such as those in the aerospace and aviation industries, the load-bearing capacity of baskets holding parts is the most pressing concern. If the baskets don’t have a sufficient load capacity to hold the parts, then they’ll break apart under the weight.

However, there are many elements that can affect the ability of a wire basket to safely carry a particular load. For example, the distribution of weight, points of contact, quality of welds, ambient temperatures, and exposure to certain chemicals can all affect how well a basket is able to bear a given load.

This is why, when a customer asks Marlin to make a heavy-duty custom wire basket for parts handling or washing applications, our design team always runs an FEA on the basket design, checking every last welded joint to see if it would bear the weight of the parts to be held. This is important because the distribution of a heavy load isn’t always consistent—sometimes parts could be loaded in a way that changes where the majority of the pressure from their weight is applied to the basket. If a welded joint or piece of wire isn’t strong enough to take the majority of the load weight, then it could easily fail despite the basket as a whole having a maximum load limit well in excess of the parts load.

Also, the virtual test allowed Marlin’s degreed engineers to simultaneously test for more than just load distribution—it allowed for the testing of a load under different temperatures and during exposure to different chemicals. This makes for more effective comparison of the basket’s ability to bear a load to its actual use conditions. Basically, our production team subjects a basket design to every conceivable kind of stress a basket may endure in a completely virtual environment!

Why Marlin Steel Uses FEA Analysis Testing for Aerospace Baskets

Here are a few reasons why finite element analysis testing helps ensure a better overall design for custom aerospace baskets.

- It keeps designers from making assumptions. One of the most dangerous things an aerospace basket designer can do is make assumptions. Aircraft steel analysis and stress testing designs eliminate the need for assumptions and spots issues that designers might fail to anticipate.

- It ensures more thorough testing than prototype tests. The ability of virtual testing to simulate years of use provides a more thorough analysis than with a physical prototype. This also helps uncover issues that would only appear after months of use.

- It allows for faster design iteration. Because many custom designs need to be completed on a tight schedule, the delays of physical prototyping may lead to corners being cut, leading to only one or two design iterations being created. Because FEA completes in minutes, dozens of design iterations can be tested to ensure that the final product’s design is as safe and polished as possible.

Case Study: FEA in Custom Wire Baskets

When a customer has concerns about the ability of a basket design to withstand the stresses involved in their processes, an FEA helps Marlin to ease those concerns. In one recent custom basket order, the client had some concerns about the load-bearing capacity of vertical bars that would be lifted via hooks for moving the basket. The client’s primary worry was that because this would put all of the basket’s weight on just a couple of points (where the hooks would contact the bars, and where the bars were welded to the wire frame), the chances of the basket suddenly breaking would increase.

So, Marlin’s engineering team ran a finite element analysis of the vertical bars and the attached wires to verify the ability of the design to hold up to being hoisted on a hook. In this test, the yield strength of the components and the weld was set at 50% (16,534.6 psi for the grade 304 stainless steel bar in question).

The vertical force exerted on the basket was 1,500 pounds of force from the weight of the parts to be held. According to the results of the test, the safety factor for the welded joint and metal bar was between 1.13713 ul at minimum and 15 ul at maximum. This meant that the design would be able to take anywhere between 1.137 and 15 times the level of force exerted in the test.

In short, the test showed the basket could easily take the stated load with room to spare. After completing the test, Marlin’s engineering team organized the results into a PDF document for the client to review. This helped to put the client’s concerns at ease, allowing production of the basket to resume in a timely fashion.

Case Study: FEA in Aerospace

A major aerospace company recently came to Marlin after having worked with another custom wire basket maker. The wire mesh on the competition's baskets was too weak to handle the client's heavy parts and would break after minimal use. On top of that, the broken wires would curl up and scratch the client’s delicate aerospace parts and allow parts to fall through the basket.

To understand the needs of this particular aerospace basket, Marlin gathered information from the client about:

- Weight of parts

- Processing equipment

- Chemicals used

- Temperature levels

- Basket handling preferences

Armed with this information, Marlin’s engineering team quickly completed an initial draft of the basket’s design and put it through the FEA process. In minutes, the simulator had projected the basket’s performance after years of exposure to the client’s manufacturing processes.

By using virtual physics software, Marlin’s degreed engineers were able to design, test, and refine the basket until it was perfect in just a day or two. Normally, such thorough testing would take months or years to achieve the same level of refinement.

Part of what the FEA testing revealed was that the old wire basket simply had too much open space between the wires to handle the client’s unevenly distributed parts. The weight would all rest on one or two wires, causing them to bend easily since they had little to no support to distribute the stress. So, Marlin’s new wire basket with handles used a much tighter wire mesh with extra-thick support wires making up the frame beneath it.

Because of this testing, Marlin’s degreed engineers were able to create the perfect basket for the aerospace company’s needs without wasting time and materials on a physical prototype. Read the full case study here.

Need a custom wire form for your aerospace manufacturing application? Contact the experts at Marlin Steel to get a quote, or for more information about Marlin’s American-made custom wire baskets.

.gif)