In industrial applications, the process of impregnation is the sealing of a porous surface so that other materials cannot penetrate that surface. It is often used in the creation of hydraulic parts that need a pressure tight seal or need to simply not absorb held fluids.

In industrial applications, the process of impregnation is the sealing of a porous surface so that other materials cannot penetrate that surface. It is often used in the creation of hydraulic parts that need a pressure tight seal or need to simply not absorb held fluids.

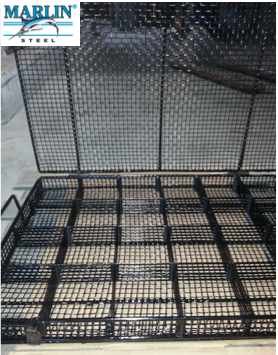

Applying a layer of resin through vacuum sealing or pressure can be tough on the containers used to hold parts through the impregnation process. So, when making a custom steel wire basket for use with impregnation equipment, those baskets need to be sturdy enough to take the pressure—not to mention exposure to the chemical compounds used in the impregnation process.

Additionally, the baskets used to hold parts through the impregnation process need to ensure that the resin or other material being used to seal the porosity of the components can easily access the parts—and not get stuck on the basket.

In one case, a client had impregnation equipment that would rotate the basket and its contents during impregnation. To keep parts from falling out, the basket needed to have a lid that could latch securely closed.

Also, the client needed the baskets to be built to tight parts tolerances, since each basket and its contents would be handled using automated equipment that needed everything to be in a precise layout.

How do Marlin Steel’s design and manufacturing teams handle manufacturing a top-quality custom wire basket for impregnation equipment that rotates the basket and its contents? Here’s how:

1: Send Out a Custom Basket Questionnaire

To ensure that Marlin’s design team can account for all of the chemicals, temperatures, and physical stresses in a client’s manufacturing process, the team first sends the client a custom basket questionnaire asking for details about their process. This is a necessary step for creating a custom basket that is compatible with all aspects of a client’s manufacturing process.

Some key details asked for include:

- A list of chemicals used in the process.

- Process time and temperature.

- An explanation of how the baskets will be moved from one process step to the next (conveyor belts, cranes, by hand, etc.).

- Maximum load weight per basket.

- Dimensions of the smallest and largest parts to be held.

- Dimensions of openings/tanks in the processing equipment.

- Clarification on how parts should be held (loose or in a specific layout).

- Parts scratch tolerance (not a concern, light scratching, or no-scratch).

Getting this information helps the design team optimize the proposed design to better meet the client’s specific needs. Even when two clients have similar processes, there may be slight differences that have a significant impact on the viability of a custom basket design. Also, this information is necessary for creating an accurate virtual physics simulation of the process.

2: Designing, Testing, and Reworking the Impregnation Equipment Basket

Once the design team has access to the completed basket questionnaire, they can begin work on creating a custom wire basket for the client’s impregnation equipment.

Here, the client had a specific need for either grade 304 or 316 stainless steel for the basket. These metals would easily resist exposure to the chemicals used in the impregnation process to keep the basket from corroding.

To keep the resin solution used in the impregnation process flowing through the basket freely, steel wires were used for the frame of the basket rather than sheet metal. This would give the basket plenty of open space for the fluid to reach the parts held by the basket. Also, because these wires were rounded, the resin would easily drain away once the impregnation process was finished.

Since the client specified that each basket needed to hold many small parts in a specific layout (for integration with their automated loading/unloading equipment), the basket needed to use dividers to create many small, separate spaces for each part. This would have the added benefit of keeping parts from touching during the impregnation process when the basket would rotate.

Speaking of rotation: a wire mesh lid was added to the top of the basket to keep parts from falling out as the basket would spin.

After finishing the first draft of the design, it was put through a finite element analysis (FEA) software program to test how well it would hold up to years of use in the client’s impregnation equipment. If the baskets would experience even the slightest deviation (so much as a human hair width), the design would fail and the basket would be redesigned to fix the issue. This process would be repeated until a design was created that could pass the test.

3: Using Manufacturing Automation to Ensure Precise Baskets

Once a design was finalized, it would be passed on to the manufacturing team for assembly. Here, the Marlin Steel manufacturing team—based in Marlin’s Baltimore, Maryland factory—would program a series of wire bending and welding machines to automate the assembly process.

This automation helped to ensure that every basket Marlin made based on the design would be identical in every way without deviations. This was important because the client’s own automated machinery would not be able to function properly if the dimensions of the baskets were off by even one inch from one basket to the next.

Also, because Marlin Steel’s factory is based in the USA, shipping to an American client could be completed quickly—without the wait for customs processing or slow overseas shipping.

Need a custom wire basket for a specialty application as soon as possible? Contact the experts of delivering Quality, Engineered Quick® at Marlin Steel today!

.gif)