When a Latin American-based manufacturer of high-tech imaging equipment reached out to Marlin Steel for a custom wire hook to use in its electroplating process for the manufacture of night vision and thermal imaging equipment, Marlin’s degreed engineers were faced with a new challenge.

When a Latin American-based manufacturer of high-tech imaging equipment reached out to Marlin Steel for a custom wire hook to use in its electroplating process for the manufacture of night vision and thermal imaging equipment, Marlin’s degreed engineers were faced with a new challenge.

Namely, the challenge was to create a wire hook using stainless steel diamond wires—which was something new for the production team. In most jobs, Marlin’s engineer work with rounded stainless steel wires because they minimize the sharp edges and reduce the risk of damage to parts. This client, however, needed diamond wires that would be more compatible with their existing equipment for their electroplating and parts finishing work.

What Are Diamond Wires?

The term “diamond wires” might be confusing—especially because there is a device known as a diamond wire cutting machine which uses small wires infused with diamonds to saw through hard materials.

However, the term doesn’t refer to the material the wires are made of, but rather to the shape of the wires. Where a normal wire is rounded so as not to have any hard edges, a diamond wire has a square shape to it.

How Working with Diamond Wire is Different

How Working with Diamond Wire is Different

With a rounded stainless steel wire, the angle of the wire coming off of the spool doesn’t make much of a difference. However, with a diamond-shaped wire, the way that the wire is fed into the machine is extremely important for meeting the client’s tolerances.

In many cases, when diamond wire is specified for a custom wire form design, the edges are meant to slot into an existing groove. If the edges are off-center, then the wire form won’t work properly, and the part will have to be rejected.

Also, the act of bending wires along an edge can blunt the edge. In some designs, this can be tolerable, but not in all of them. Preserving these edges while bending diamond wires is a challenge that requires specific wire bending equipment and know-how to pull off with consistency.

Making Custom Diamond Wire Hooks for Electroplating

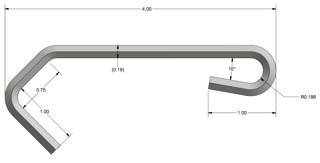

For this particular stainless steel diamond wire hook, the client needed the edge of the wire to be on the inside edge of the bend, and to remain semi-sharp. Blunting the edge of the wire would have made it less compatible with the client’s existing equipment. Also, each piece of wire needed to have three bends—one tight, rounded bend to be semi-permanently slotted onto a basket, and two looser bends that would make it easy to slip the hook over (or off of) other objects.

To achieve the tight internal bend without blunting the wire’s edge, the wires needed to be bent from the outside of the bend rather than from the inside—which is how most of Marlin’s robotic wire bending armatures work. So, Marlin’s production team used a CNC press brake to finish the rounded bends.

The press brake was able to bend numerous wires at once with each operation by taking wires that were partially bent using the wire bending armatures and completing the bend by pressing the wires from the outside edge. This helped to minimize the blunting of the inside edge of the wire so it would fit into the grooves of the client’s basket more easily.

Want to know more about how Marlin Steel can help you meet your production needs with a custom wire form? Contact us today to speak to an experienced mechanical engineer. Or, learn more about custom wire forms by reading our free guide at the link below:

.gif)