The American manufacturing industry represents a solid opportunity for American citizens to find jobs that can support a middle-class family. According to data from indeed.com, in 2019, the average annual salary for manufacturing engineers in the USA was $77,313—though many manufacturing engineers with specialist skills and qualifications can easily earn six figures.

The American manufacturing industry represents a solid opportunity for American citizens to find jobs that can support a middle-class family. According to data from indeed.com, in 2019, the average annual salary for manufacturing engineers in the USA was $77,313—though many manufacturing engineers with specialist skills and qualifications can easily earn six figures.

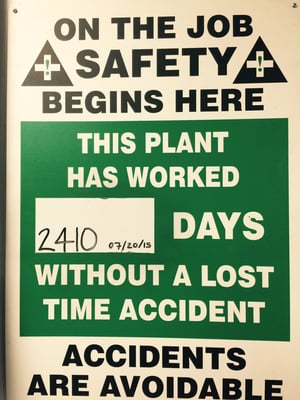

However, American manufacturing companies struggle to find qualified applicants to fill engineering jobs. Part of the problem is that the public image of manufacturing work is still stuck in the industrial revolution. However, reforms in American manufacturing techniques and the oversight of organizations such as OSHA (the Occupational Safety and Health Administration) have greatly improved manufacturing safety in the last few decades.

The truth is that modern manufacturing jobs are among some of the safest jobs in the U.S. An article featured in AJC listed the top 25 most dangerous jobs in America—and manufacturing was not on the list. Instead, trades like fishing, logging, flight engineering, roofing, and refuse/recyclable collection topped the list.

To help raise awareness of safe manufacturing techniques, and to celebrate the company’s history of manufacturing safety, the Marlin team put together a list of safety tips for bending metal forms.

Manufacturing Safety Tip #1: Inspect Bending Machinery Regularly

Sheet metal press brakes and other metal forming machinery are incredibly complex and powerful. For example, some of Marlin’s metal bending equipment can exert more than 40 tons of force and have dies that are attached to equipment weighing several hundred pounds.

So, frequent inspections of metal bending equipment are a necessity for Marlin’s employees. Mechanical engineers routinely inspect metal bending machines before their activation and during the initial startup, carefully recording any issues and recording them in a repair log. This helps to keep Marlin’s press brakes and other equipment in tip-top shape so it can be safely used at maximum capacity.

Manufacturing Safety Tip #2: Make Sure New Degreed Engineers Fully Understand the Machine’s Operation

Marlin Steel invests heavily in employee training to ensure that everyone on the shop floor thoroughly understands how the machines they use work. In fact, many employees train on multiple machines so multiple people can operate the same device—or stop it in case of an emergency.

Even after going through online training in how to use a machine, Marlin’s manufacturing engineers are often walked through the proper operating procedure for a metal bending machine before they use it for the first time. Having an experienced engineer walk new users through the use of a piece of heavy machinery helps increase safety by having someone who knows what is or isn’t normal for that equipment supervising.

Manufacturing Safety Tip #3: Leverage Computer-Controlled Automation

Many of Marlin’s metal-forming machines are partially or fully automated—requiring little or no human interference once they’re set up. This allows Marlin’s manufacturing engineers to assume a supervisory role where they can monitor the shaping of metal from a safe distance.

This removes the need for Marlin’s employees to blow out their shoulders, backs, or hands trying to manually shape inch-thick steel with crude handheld tools. Instead, the machine can handle the repetitive motion task. So, there are fewer cases of carpal tunnel and more completed custom wire baskets that meet incredibly tight parts tolerances.

Manufacturing Safety Tip #4: Always Wear Protective Clothing

Even when Marlin’s employees are simply supervising automated equipment rather than actively working with metal, they still wear appropriate safety gear for the process if they’re going to be in the same room as that process.

For many processes, this includes:

- Gloves

- Goggles

- Headwear

- Thick, protective clothing

- Work boots

Other specialized equipment may be required for specific metal forming processes. For example, laser cutting or arc welding processes may require polarized lenses and full face helmets to protect the wearer from stray sparks and flashes.

Manufacturing Safety Tip #5: Periodically Review Safe Manufacturing Practices with Employees

One of the things that Marlin Steel’s leadership does to help encourage employees to keep manufacturing safety top of mind is to empower employees to review safety standards and recommend changes.

There is a safety committee made of Marlin Steel employees who help to oversee the creation of new safety standards based on the observations and recommendations of other employees. Because these new rules are coming from peers who understand the challenges of their work, Marlin’s manufacturing engineers are more likely to listen to these new recommendations. Even better, experienced degreed engineers on a committee like this are more likely to be able to recognize potential problems with a new safety standard that impact its practicality or enforceability.

Everyone at Marlin Steel is proud to be part of an extremely safe and rewarding workplace that value the health and wellbeing of its employees. If you have any questions about Marlin, please contact us.

.gif)