With many manufactured products, any kind of deformities in the surface condition of a part or in the angle of a joint can ruin the part’s functionality.

With many manufactured products, any kind of deformities in the surface condition of a part or in the angle of a joint can ruin the part’s functionality.

For example, say that a welded joint in a part is completed in a manner that causes the welded parts to be misaligned by a few degrees. This deformity could cause other pieces that are supposed to be joined to the welded part not to fit properly, preventing completion of assembly.

The end result is that you have to either completely scrap the part, wasting any time, labor, and materials that have already been poured into it, or spend resources fixing the part so that it is usable.

In short, deformities in your products increase your costs and reduce your productivity.

With this in mind, how can you prevent deformities in your manufacturing process? Here are a few ideas:

Review Your Manufacturing Techniques

Before you go about the task of fixing your manufacturing process to eliminate the causes of deformities in your products, it’s important to do a thorough review of your production process to see where the majority of deformities are being introduced and what their causes are.

Hopefully, you already have a system in place for recording when a part is rejected and why. This will help you identify where deformities are being introduced to parts quickly so you can address the issue.

For example, if you notice that a majority of your deformity-related parts rejections occur right after your parts washing process completes, you know that there’s an issue with that process which might be causing damage.

Or, to recall the earlier example of weld-based deformities, you notice that your welding process leaves parts frequently misaligned or laden with excessive spatter. You might be able to prevent further deformities by changing the welding techniques and equipment you use.

Minimize Manual Processing of Parts

Even the best workers make mistakes. This is especially true after said workers are several hours into a shift of tiring, repetitive, labor-intensive work. This naturally leads to errors in the exact angle of a metal bend or in the placement of a weld, leading to small variances and deformities.

For parts where consistently precise measurements in the part area must, using automated manufacturing equipment is enormously beneficial. Robots, unlike their human counterparts, don’t get tired or sore after a few hours of labor and start making bad parts. Manufacturing robots will keep making parts with identical bends from dawn till dusk every day.

This helps to prevent the common human errors that lead to major deformities in parts.

Keep Parts Separated During High-Intensity Finishing Processes

Many times, a part is manufactured to near perfection, only to suffer scratches and dents during the parts finishing process.

Many times, a part is manufactured to near perfection, only to suffer scratches and dents during the parts finishing process.

Why? Because parts end up colliding with one another during the finishing/cleaning process.

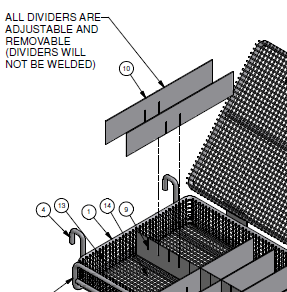

Here, one of the best ways to prevent surface damage to parts is to keep them separated by using a parts washing container with dividers, or a wash basket that is custom formed to hold parts securely in place throughout the wash process. This keeps parts from colliding and damaging one another.

This, naturally, may require a redesign of the parts handling baskets/trays that you use for your production line.

Find out how you can improve your manufacturing team's productivity with a well-optimized custom steel wire basket by checking out the link below:

.gif)