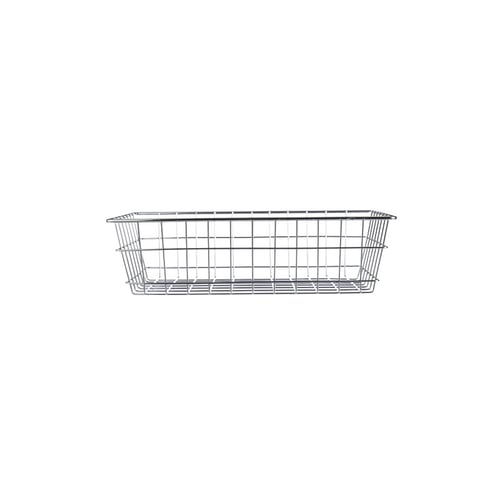

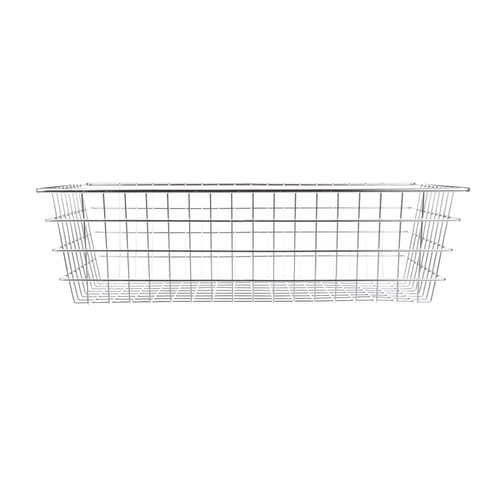

Metal Wire Food Baskets • Custom & In-Stock

Wire Food Baskets From Marlin Steel: Improve Food Processing Safety, Speed, & Cost Efficiency

Wire Food Baskets From Marlin Steel: Improve Food Processing Safety, Speed, & Cost Efficiency

Any business that produces, processes, or transports consumable goods is subject to strict regulations that govern product quality, safety, and hygiene. With a background in serving the food and beverage sector, Marlin Steel Wire Products LLC got its start in commodity bagel baskets, giving us vast industry and regulatory knowledge to support your operations. We specialize in standard and custom wire and steel products, offering durable food-grade metal wire baskets and more for clients in food processing. Our team can assist you in adhering to regulations while supporting your timeline and budget requirements.

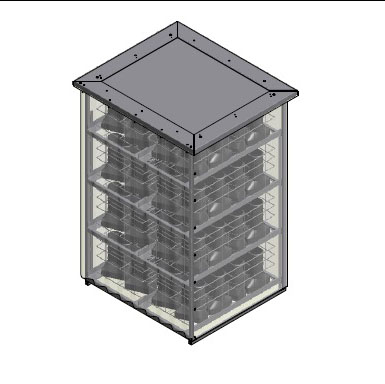

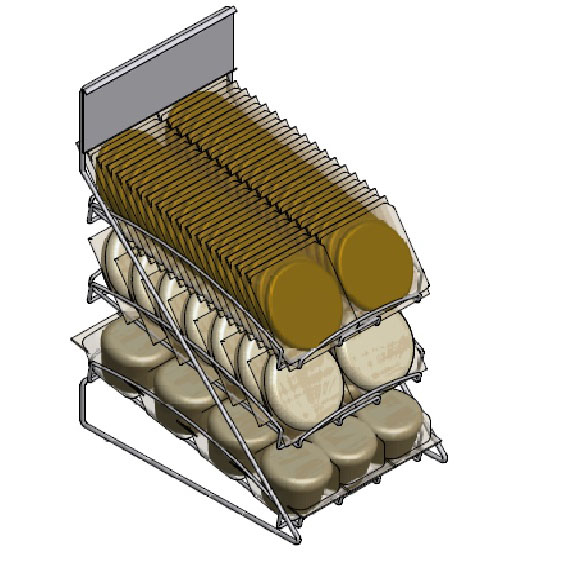

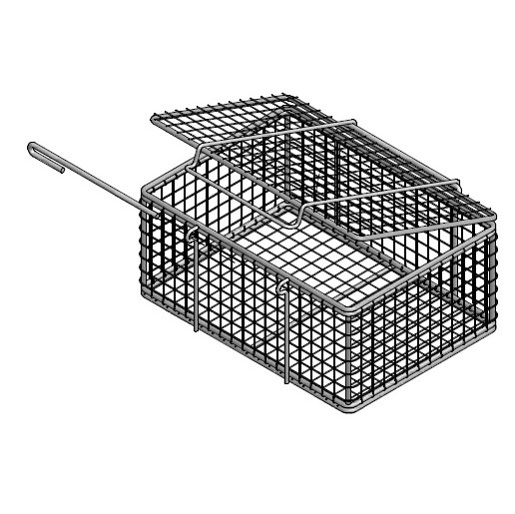

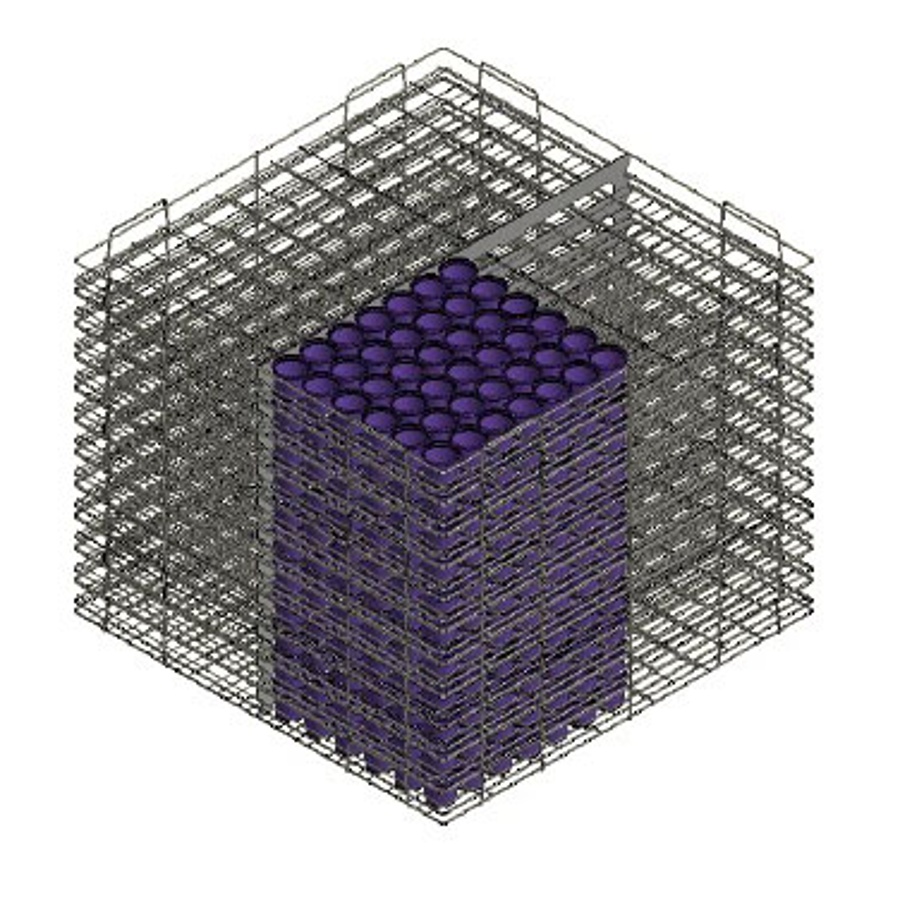

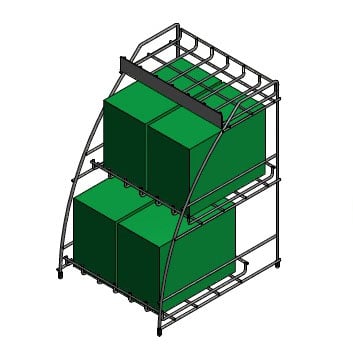

At Marlin Steel, we design our wire products to safely and efficiently handle versatile tasks. From wire food baskets and trays to racks and displays, our food-safe wire forms will support your operation by:

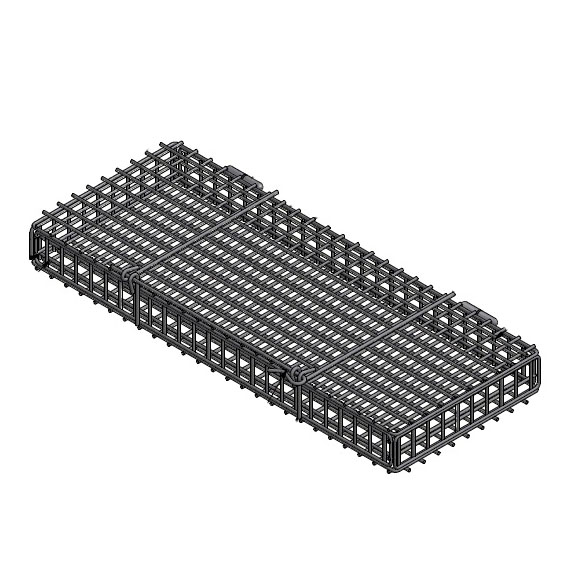

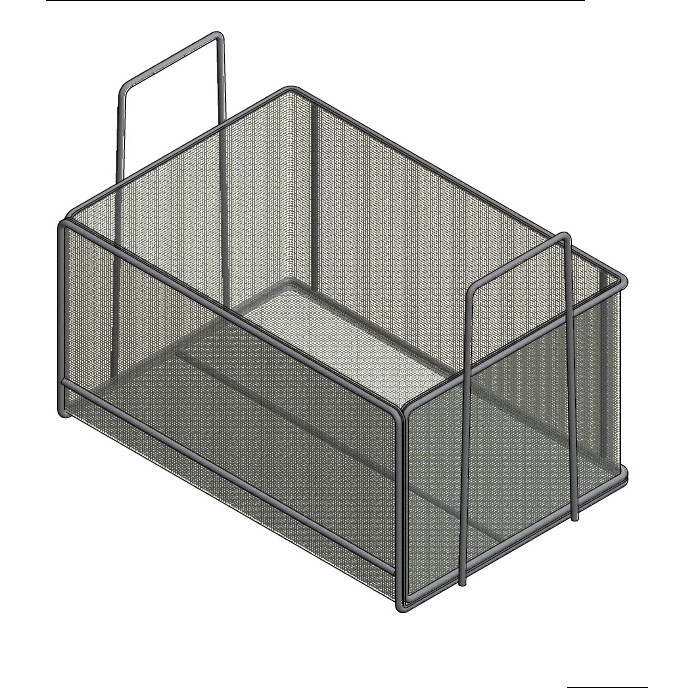

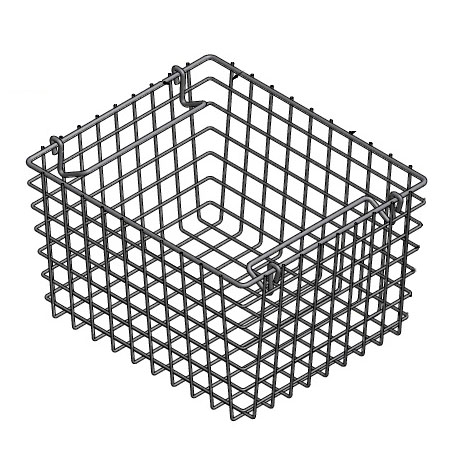

We can make our stainless steel baskets with an electropolished finish. This finish smooths the basket on a microscopic scale so germs and food byproducts won’t stick to the metal. Also, food-grade stainless steel has a very high melting point, so it can withstand heat-based sanitizing methods with ease.

Our food-grade wire baskets offer enormous customization opportunities, specifically in regard to the wire spacing. This allows for the creation of a food-grade wire basket with optimum air flow to speed your processes along or allow byproducts to drain easily. This prevents liquids from pooling in the basket, eliminating a major contamination risk.

Marlin’s stainless steel food-grade wire baskets can be customized to withstand a variety of temperatures and chemicals. This allows the same baskets to be used with the majority of your equipment—from oven to freezer. Being able to keep your food in one processing basket from start to finish minimizes handling time and increases your production throughput.

Partnering with Marlin Steel will help ensure that your metal wire food baskets adhere to industry regulations for food-safe operations. All of our food baskets, trays, racks, and related products are 100% made in the USA and backed by Marlin Steel's 55+ years of experience. We believe in Quality Engineered Quick®, offering high-quality products tailored to your application to meet your needs for performance, fast delivery, and cost-effectiveness.

Contact us to learn more about our in-stock and custom food basket solutions, or request a quote today to get started.

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797