“Fast Delivery, Incredible Quality”

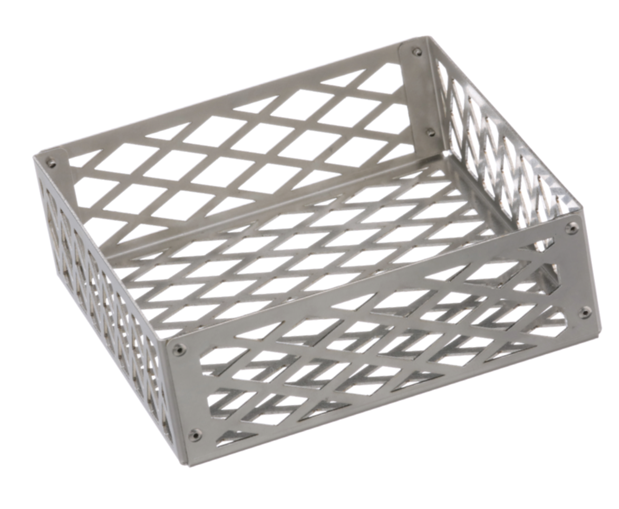

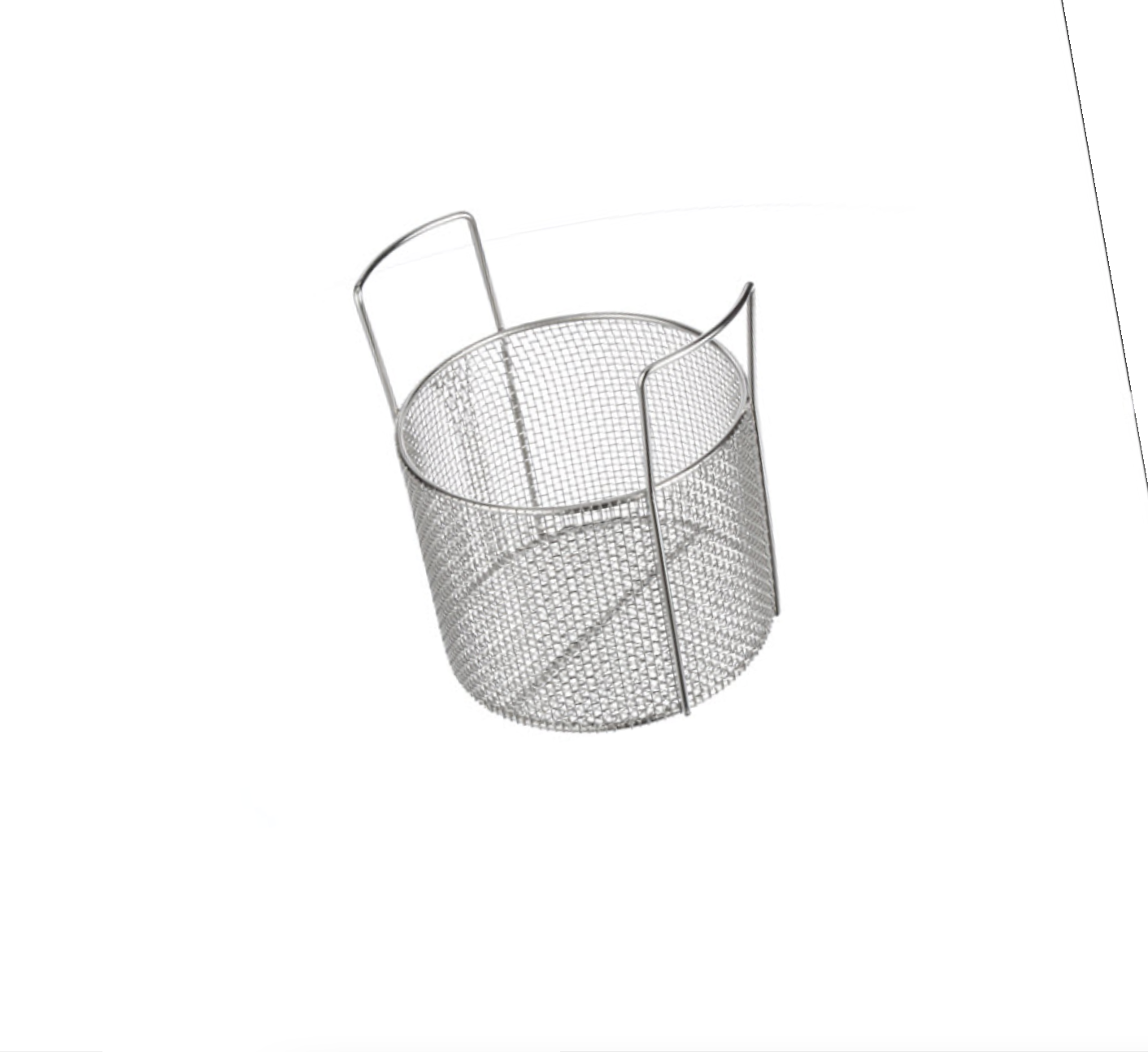

Marlin Steel Wire Products LLC is a leading manufacturer of high-performance sheet metal and steel wire forms and baskets, working with a diverse client base since 1968. To meet widely varied needs, we produce and stock standard baskets for fast order fulfillment while offering custom wire basket fabrication services to deliver solutions tailored to your specific requirements for shape, size, material, and basket features or properties. Our custom-made wire baskets will last you for years or even decades with proper material composition and care, reducing expenses on basket replacements over time.

Discover the advantages of custom wire baskets for various industries, and learn how Marlin Steel's team of mechanical engineers can help support and streamline your operations by designing, perfecting, and producing high-quality custom baskets for your application. Additionally, Marlin Steel's ISO 9001:2015 and ISO 13485:2016 certifications demonstrate our commitment to quality and regulatory compliance, ensuring that our customers receive products that meet the highest industry standards.

Companies big and small rely on Marlin Steel for custom metal wire basket solutions. Each of our baskets is:

At Marlin Steel, we take a collaborative approach to design, working closely with your team to develop custom wire baskets that meet your unique requirements. Using sophisticated virtual testing software such as Autodesk to vet basket designs, our degreed engineers eliminate the time-consuming process of making endless prototypes that wouldn't work, saving you time and money.

We'll build your wire baskets quickly and with a level of consistency that manual labor simply can't match. Anything you need can be precision-manufactured with rapid delivery thanks to the speed, efficiency, and accuracy of our automated fabrication solutions.

We incorporate robotics into our wire mesh basket manufacturing process to achieve uniform quality in high-volume production runs. These robots assemble wire forms morning, noon, and night without getting tired. This allows for not only fast production of your baskets but also ensures that each basket meets your tolerances, from the first to the last. Our team also works with such advanced factory automation solutions as wire-bending robots and a medium-frequency direct current welder generating the best welds in the USA.

Our team is experienced in working with a range of high-quality materials so that we can provide you with options suited to your wire basket applications. Our selections include:

When you partner with Marlin Steel for your custom metal baskets, you can select from more than 40 different coating and finishing options to enhance their performance and aesthetics. Our mechanical engineers will help you find the ideal coating or finish for your project, with common examples including:

Critical industries worldwide depend on Marlin Steel to design and manufacture custom metal baskets to their exact specifications and tolerance requirements. Our versatile metal wire baskets are ideal for numerous applications, including parts and material handling, high-temperature sanitation and sterilization, ultrasonic cleaning, aqueous parts cleaning, and vapor degreasing. They're beneficial for such industries as:

As your custom wire basket manufacturer, Marlin Steel provides rapid global delivery of 100% USA-made products as part of our focus on Quality Engineered Quick®. We integrate industry expertise, extensive design and production services, a team of highly skilled degreed engineers, and state-of-the-art factory automation to produce custom metal forms with precision.

As evidence of our commitment to quality, Marlin Steel is an ISO 9001:2015-certified and ISO 13485:2016 company, and upon request, we have our ASME BTH 1 2008 standard compliance form available. We've also received OSHA's SHARP award for our achievements in workplace safety.

Looking for a quote or trying to determine which type of wire basket is the best fit for you? Our wire baskets are custom designed to suit your specific needs! Reach out to one of our experts to discuss your options today.

For medical device manufacturers, sterility, repeatable performance, and surface integrity are non-negotiable. The surgical instruments, implant ...

Read More

At Marlin Steel, reshoring has helped create and sustain good jobs for American workers. These are people building meaningful careers in ...

Read More

In medical and pharmaceutical environments, reliability isn’t optional; it's required. From sterilization trays to washing baskets and transport ...

Read More

Using virtual testing software such as Autodesk to vet basket designs, Marlin Steel engineers eliminate the time-consuming process of making endless prototypes that wouldn’t work, saving time and money.

By employing advanced factory automation, including:

Marlin Steel can build wire baskets very quickly and with consistency that manual labor simply can’t match effectively. They can be custom designed to suit your specific need. These robots assemble wire forms morning, noon, and night without getting tired. This allows for not only fast production of your baskets, but ensures that each basket meets your tolerances, from the first to the last.

Marlin Steel crafts unique custom basket designs for clients in many different industries all across the globe. Clients in the automotive and aerospace industries rely on Marlin Steel’s factory automation know-how and tools to manufacture custom metal forms to exacting tolerances.

Businesses both large and small count on the knowledge of Marlin Steel mechanical engineers to perfect every aspect of their custom wire basket’s design, from the shape of the basket to the materials used in it. With the right materials, your baskets will last you for years or decades so that you only have to pay for them once instead of having to waste money year after year on reorders.

Anything you need can be precision-manufactured with rapid delivery thanks to the speed and consistency of our automated manufacturing equipment. Any style of metal basket can be engineered to meet your specific needs. There are a wide range of finishes and coatings that our mechanical engineers will help you select.

Looking for a quote or trying to determine which type of wire basket is the best fit for you? Our wire baskets are custom designed to suit your specific needs! Reach out to one of our experts to discuss your options today.

At Marlin Steel, we are known for our precision-engineered wire baskets that keep production lines moving efficiently. But many manufacturers ...

Read More

Ultrasonic cleaning for parts plays an important role for many of today’s manufacturers. It saves them time and money, and compared to manual ...

Read More

Aircraft maintenance, repair, and overhaul is a vital component within the aerospace industry. After all, in aerospace, the margin of error is ...

Read More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

Looking for a quote or trying to determine which type of wire basket is the best fit for you? Our wire baskets are custom-designed to suit your specific needs! Reach out to one of our experts to discuss your options today or fill out the form below:

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797