The gun manufacturing process must balance efficiency with precision. As any flaws in gun manufacturing can negatively impact the quality of the firearm, gun manufacturers are constantly striving to ensure product quality is maximized.

The gun manufacturing process must balance efficiency with precision. As any flaws in gun manufacturing can negatively impact the quality of the firearm, gun manufacturers are constantly striving to ensure product quality is maximized.

Fortunately, there are gun manufacturing methods that can be implemented to ensure precision and sterility. Ultrasonic cleaning has grown in popularity among manufacturers across industries as a way to remove any debris or dirt from the manufacturing process. From aerospace engineering to automotive parts manufacturing, ultrasonic cleaning can remove normally hard-to-clean oil and contaminants from narrow gaps and ridges.

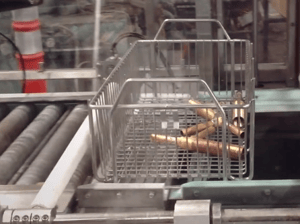

For gun manufacturers, ultrasonic cleaning offers numerous advantages when it comes to keeping firearms clean from contaminants that may otherwise compromise the integrity of the product. Wire baskets specifically designed for ultrasonic gun cleaning can streamline operations and ensure the firearms are protected throughout the whole process far more than traditional alternatives.

How Ultrasonic Cleaners Work

Ultrasonic cleaners utilize high-frequency sound waves to physically shake a caustic cleaning solution. These sound waves are powerful enough to induce “ultrasonic cavitation,” the formation of small bubbles within the caustic solution.

When these bubbles burst, they essentially produce a shock wave against the object placed in the cleaning solution. These shock waves are strong enough to clean the surface of the object by loosening contaminants from the surface. Cavitation is able to penetrate hard-to-reach areas, such as narrow recesses, that conventional cleaning methods are unable to access. Ultrasonic cleaning also improves the abilities of the cleaning solution so that the objects being washed are as debris-free as possible.

Choosing Wire Baskets for Ultrasonic Cleaning

Wire baskets can enhance the ultrasonic cleaning process and increase operational efficiency. The firearms parts being cleaned are loaded into the basket, which is lowered into the ultrasonic cleaning solution. After the operation, the basket is lifted out so the newly- cleaned parts can dry.

cleaned parts can dry.

A high-quality wire basket can deliver numerous benefits for gun manufacturers. Here are some of the top advantages wire baskets can deliver to ultrasonic gun cleaning:

Corrosion Resistance

Wire baskets for ultrasonic cleaning machines must be able to resist corrosion from being completely submerged in the cleaning fluid repeatedly. Cleaning solutions for ultrasonic cleaning processes are extremely caustic, with pH levels low enough to remove lime deposits, oil, grease, dirt, oxide layers, and any other debris.

If wire baskets without enough corrosion protection are used, they can develop rust, which may rub off on the gun parts being held and damage them. The rust may even weaken the wire basket enough for it to break mid-operation. High-quality baskets should be made out of durable materials, such as stainless steel, to prevent corrosion.

Resistance to Vibrations

The high-frequency sound waves used in ultrasonic cleaning are powerful enough to damage weak baskets. Wire baskets need to be durable enough that repeated exposure to these intense vibrations won’t weaken them. This may mean baskets are made with thicker steel wires with lots of welds than typical metal baskets.

The design and durability of your ultrasonic baskets will depend on your intensity of your generators. Ultrasonic cleaning machines will have different levels of intensity for their ultrasound generators. The stronger the generator, the more intense the vibrations and the thicker the basket will need to be.

Protection for Held Parts

Baskets help to protect the small and delicate parts being washed. Otherwise, they may fall out or damage themselves during the cleaning process. Depending on how delicate the parts being washed are, baskets can be customized for added protection so there is no part-to-part contact and a risk of scratches or dents.

out or damage themselves during the cleaning process. Depending on how delicate the parts being washed are, baskets can be customized for added protection so there is no part-to-part contact and a risk of scratches or dents.

It may even be necessary to prevent any part-to-metal contact. Baskets can be made with soft polymer coatings to cushion the impact when parts hit the inside of the basket and prevent damage.

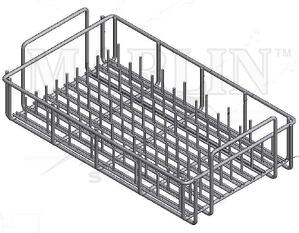

Why Marlin Wire Baskets Are the Right Choice for Gun Manufacturers

When you need a high-quality wire basket, Marlin Steel has everything you need. Marlin’s baskets are made of stainless steel to prevent corrosion and designed to withstand repeated impacts from ultrasonic cleaning vibrations.

Additionally, any of Marlin Steel’s baskets can be customized to fit your exact ultrasonic cleaning needs. This means it will be properly designed to fit the exact dimensions and protection requirements for your gun parts. Marlin’s engineering team has years of experience in crafting custom stainless steel wire forms and can design one customized with your specific gun manufacturing needs, including taking into account the weight of the held parts, the thickness of the wires in the mesh, and the intensity of the ultrasonic vibrations of your machine.

So, If you are ready for more efficient gun manufacturing with Marlin Steel wire baskets, or if you need advice for picking the right stainless steel basket for your needs, reach out to the team at Marlin Steel.

.gif)